The most robust kappa measurement available in the market today

Valmet Brown Stock Analyzer

The most robust kappa measurement for high yield and brown pulp, designed to measure the coarsest pulp starting from cooking blow line.

Precise process controls with dual sampling

Reduce Kappa number variations for higher pulp yield

Improve recovery boiler performance and lower operational costs

Real-time analysis for digester and washing control

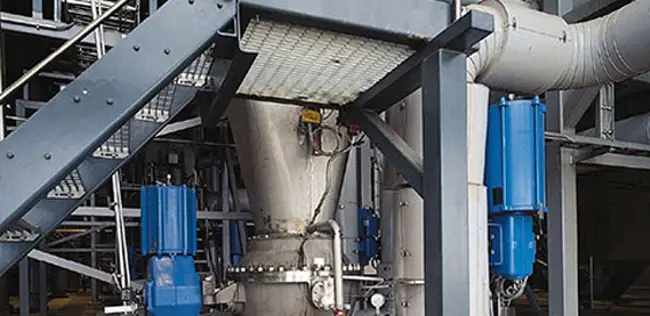

The Valmet Brown Stock Analyzer provides high-frequency Kappa analysis for digester and brown stock washing control in kraft pulping. Designed for high yield and brown pulp, the analyzer can measure the coarsest pulp starting from the cooking blow line.

Utilizing well-proven sampling technology, the Valmet Brown Stock Analyzer automatically extracts pulp samples for analysis. After dissolved lignin is thoroughly washed, the pulp is analyzed with advanced optical measurement technology.

Valmet’s offering is a unique solution for dual or single blow line and brown stock washing applications. Getting Kappa numbers right enables precise process control and optimization without delays. Achieve high operational savings through tighter cooking, oxygen delignification and bleaching controls.

Safe and easy implementation

The sampler and sample line installation only require a brief shutdown while the analyzer itself can be placed in a convenient location. The analyzer keeps operators away from harsh process environments.

Innovative sample handling minimizes water consumption and ensures reliability even with high shive content pulps. Pre-calibration with customer pulp samples makes commissioning exceptionally fast, while few moving parts keep maintenance minimal.

With a built-in touch screen display, operating parameters, sequences, and diagnostics are instantly available. Versatile remote connectivity including Valmet Industrial Internet capability enables efficient follow-up and support, both locally and from Valmet Performance Center.

Unique Kappa profile for batch digester

For a Kappa profile measurement, the analyzer is capable of taking multiple samples to the sample line during a batch digester blow sequence. After the blow sequence, the analyzer measures individual samples and provides a Kappa profile from the selected batch digester.

This Kappa profile can be used to optimize the cooking parameters of each digester and further improve yield and pulp quality. Additionally, the analyzer can provide an average Kappa number from several samples.

Downloads |

||

|---|---|---|

| Valmet Brown Stock Analyzer Brochure | ||

Related optimization solutions