Steam treated pellets

“Steam treated pellets or Black Pellets” is the name for a thermally-treated biofuel pellets intended for substitution of fossil-coal in heat and power production. Steam treated pellets can be produced from basically all cellulosic materials such as wood, wood residues and agricultural residues.

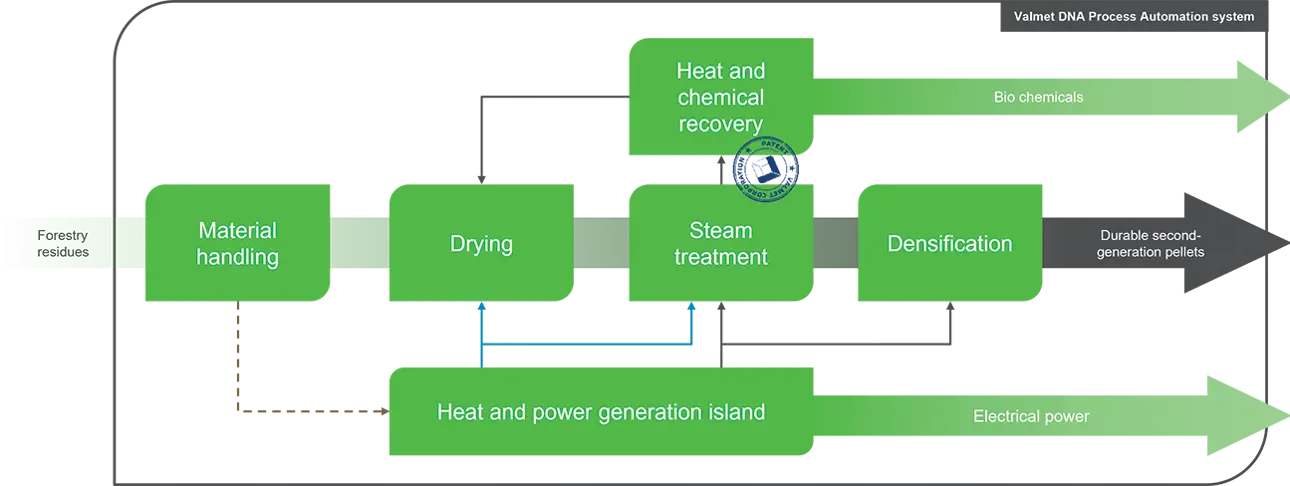

Valmet provides all technology steps needed from raw material infeed ending through to discharge of pellets including integrated Heat and Power plant for generation of energy for the process as well as export of electricity to the grid. Our wide range of offering also include Valmet DNA automation system for control of the process. A system for heat and chemical recovery is well integrated into the concept. The chemical recovery provides a second revenue stream by separating out renewable based furfural from the biomass.

The main benefit with steam treated pellets are:

- Moisture resistant

- High dry and wet durability

- About 30% higher energy density compared to white pellets

- Saves cost in logistics as a durable pellet

- Saves cost as little to no need for rebuild at heat and power plant when changing from coal

Valmet's potential offering

A complete steam treated pellet plant with CHP integrated

Our expertise is at your service

Our focus is to bring your performance forward. Get in touch with us through our website, or through your local Valmet office.

Contact us