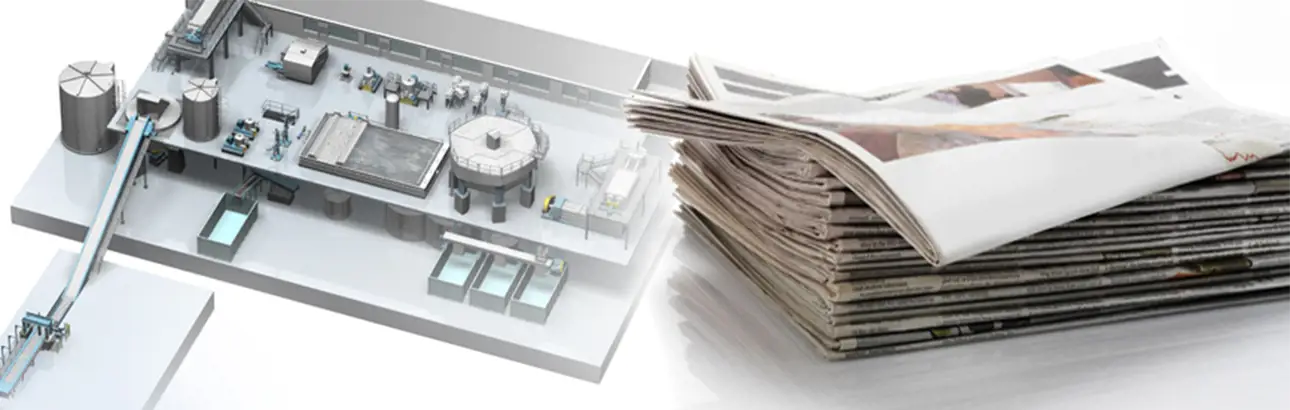

Deinking Plants

The production of high-quality printing papers, newsprint, and tissue from recycled fiber is challenging and mills need to handle more furnish variability, as paper qualities get mixed and contaminated with non-fiber materials.

Valmet offers innovative deinking technologies and cost-effective subprocesses, from pulping to stock preparation for efficient impurity removal, high yield, controllable ash content, and high brightness gain.

Advanced process controls from Valmet further maximizes your process performance to ensure stable quality furnish for the production of high-quality paper grades.

You can also come to visit Valmet Fiber technology Center and test various opportunities to improve your competitiveness through pilot trials.

Valmet solutions