Valmet impingement drying

Revolutionary drying technology for effective drying

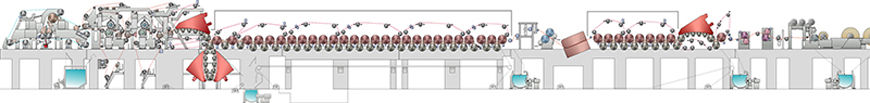

Impingement drying is a very efficient way of drying the paper web that uses air as the drying medium. Effective drying is gained by blowing hot, high-velocity air onto the sheet and circulating the air back to the dryer. This method yields a considerably higher specific evaporation rate than conventional cylinder drying thus enabling shorter paper and board machines and machine rooms. The drying air is heated with gas providing flexibility for drying energy concepts.

Different solutions for replacing and improving traditional cylinder drying

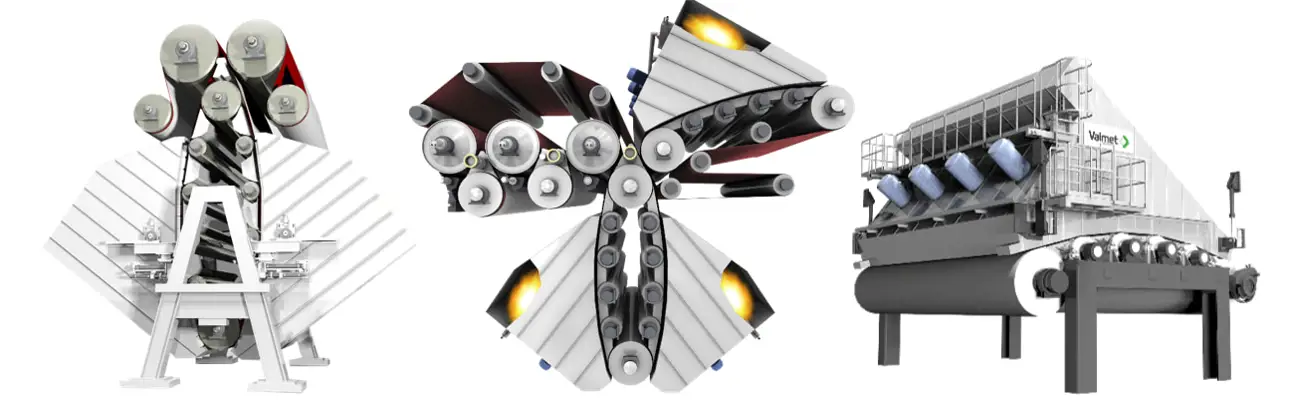

OptiDry impingement drying technology has been developed both to replace and to improve traditional cylinder drying technology. It is the most effective way to dry paper. We have three impingement drying solutions offering different benefits for papermakers.

The revolutionary OptiDry Twin represents impingement drying technology that provides superior drying efficiency. Resulting in excellent runnability, enhanced draw control and increased bulk. OptiDry Vertical is the rebuild dryer increasing drying capacity without adding machine length. It is placed under the existing dryer section with minimal changes to current layout. OptiDry Curl offers energy efficient curl control for single felted dryer sections.

One example of the superior qualities of OptiDry impingement dryers is Zhanjiang Chenming PM 1 in China with OptiDry Twin and OptiDry Curl impingement dryers and world record speed.

Valmet impingement drying offers an advanced and sophisticated way to increase machine production, efficiency and end product quality, in an energy-efficient way, on both new and rebuilt paper or board machines.

Want to talk to our drying experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our experts

How to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. But where do you start? Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Download e-bookExplore our latest board and paper press releases

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States

- Jul 8, 2024Discover Valmet MTC Wizard at Tissue Innovation Days 2024: the latest technology enhances Client benefits in Tissue Folding

- Jul 2, 2024Valmet to supply a high-capacity winder to Wuzhou Special Paper in China

- Jun 26, 2024Valmet to supply both a papermaking line and a paper machine rebuild to a customer in Asia-Pacific

- Jun 25, 2024Valmet to deliver a tissue machine to Andhra Paper in India

- Jun 19, 2024Valmet receives the second order of converting lines to Metsä Tissue in Mariestad, Sweden

- Jun 13, 2024Valmet and Flootech enter partnership to advance water treatment for the board, paper and tissue industry

- May 30, 2024Valmet enters joint venture with Körber to advance the digital offering to the tissue industry

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China