Reliable consistency measurements for pulp and paper

Valmet Consistency Measurements

Valmet has designed and engineered an optimum set of tools to control consistency in any application. Over 70 years of research and development, including independent verification and levering a fully TAPPI-standardized lab, stand behind every solution. Consistency transmitters are developed especially for pulp and paper processes aiming to provide reliable, accurate, and durable sensors that tolerate process disturbances and harsh conditions. Valmet’s consistency portfolio covers all the pulp and paper applications; from chemical pulp mill digester to dryer machine and repulper, to paper, board, and tissue machine pope reeler.

Higher consistency control performance

Improved end-product quality and process efficiency

Savings in raw materials, chemicals, and energy

Continuous and stable real-time measurement improves predictability

Our consistency solutions

Valmet Measurement Advisor

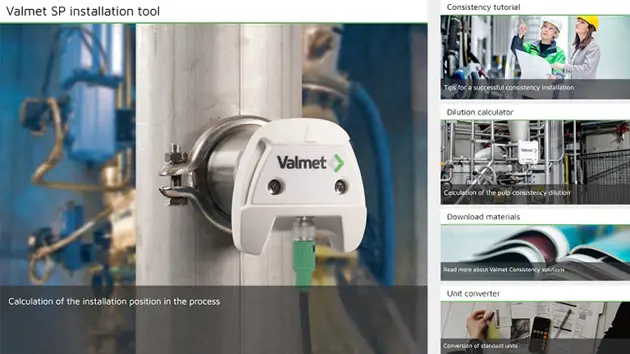

Valmet Measurement Advisor is a tool developed to help you select the most applicable installation position for Valmet Blade Consistency Measurement in the process.

Read more