New lines

Sustainable papermaking process with innovative technologies

Defining suitable production capacity is the key to ensuring the highest possible return on paper machine investment. Our focus is on supplying the right scale papermaking lines with sustainable solutions to serve local as well as global markets. Production can be focused on those products where demand and prices are the most profitable.

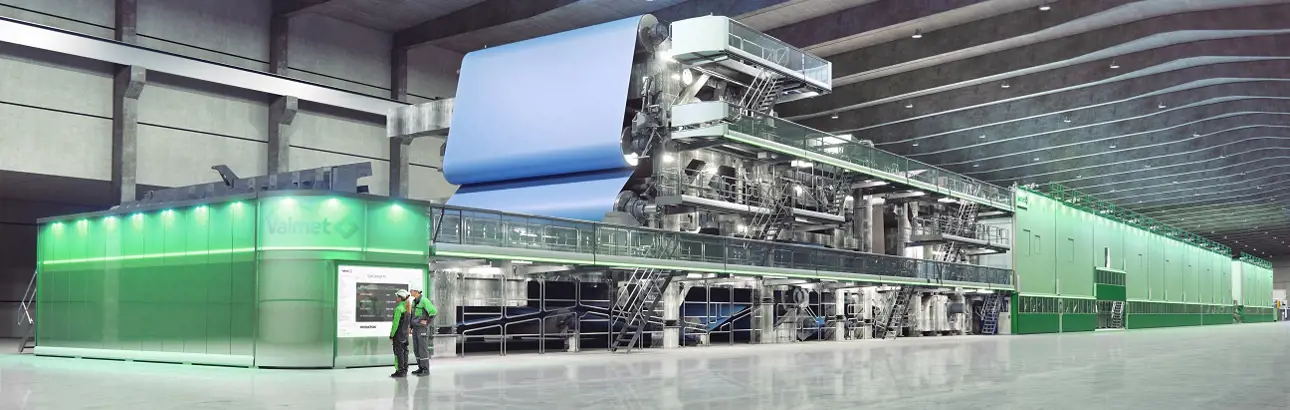

OptiConcept M - Maximum efficiency with minimum operating costs

OptiConcept M is a modular paper machine concept for sustainable papermaking. OptiConcept M family suits containerboard, cartonboard and fine paper production – simple, well-functioning solutions that meet customers’ needs.

OptiConcept M paper machine keeps costs down by increasing energy, raw material, and chemical efficiency. It provides improved flexibility in grade changes and enables efficient operation and maintenance-friendly design that maximizes productivity and minimizes downtime. OptiConcept M stands for economy, safety, and the environment.

Secure your investment with pilot trials

Valmet Paper Technology Center provides the world's most comprehensive offering of testing and piloting services to paper and board manufacturers worldwide. Our pilot facilities have the entire paper machine process covered, from stock preparation to coatings and everything between, providing customers with excellent service and reliable results to support in investment decisions.

Follow the activities in the trials on site or remotely through live streaming cameras. Pilot trials are very cost-efficient compared to expensive tests in paper and board maker's own production. Naturally we work under strict confidentiality.

Read more about Paper Technology Centers and pilot trial opportunities

Accelerate start-up and optimization with Industrial Internet solutions

The start-up and the further optimization of a new paper machine can be supported remotely from Valmet Performance Center. Data-based and proactive remote support is a fast and efficient way to ensure that the machine is meeting the planned start-up curve. During the ramp-up phase, the advanced monitoring and prediction applications help to optimize end-product quality, energy consumption, and productivity.

Our expertise is easily available for you through the Performance Centers. Our specialists have a deep understanding of machinery, processes and automation and with remote connections and tools, we can offer the needed support and guidance without delay – and more broadly than before.

Want to talk to our board & paper experts?

If you wish to get further information like technical specifications or details, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsExplore our latest board and paper press releases

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States

- Jul 8, 2024Discover Valmet MTC Wizard at Tissue Innovation Days 2024: the latest technology enhances Client benefits in Tissue Folding

- Jul 2, 2024Valmet to supply a high-capacity winder to Wuzhou Special Paper in China

- Jun 26, 2024Valmet to supply both a papermaking line and a paper machine rebuild to a customer in Asia-Pacific

- Jun 25, 2024Valmet to deliver a tissue machine to Andhra Paper in India

- Jun 19, 2024Valmet receives the second order of converting lines to Metsä Tissue in Mariestad, Sweden

- Jun 13, 2024Valmet and Flootech enter partnership to advance water treatment for the board, paper and tissue industry

- May 30, 2024Valmet enters joint venture with Körber to advance the digital offering to the tissue industry

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China