Mondi Ružomberok PM 19 – A complete delivery from OCC to board

Jun 7, 2023

Mondi Ružomberok started up a new containerboard machine at their mill in Slovakia with support from Valmet.

Project background

The city of Ružomberok lies in a beautiful region of Slovakia, surrounded by the forests, hills and rivers of the Liptov region and the Low Tatras mountain range. The Mondi Ružomberok mill is on the outskirts of the city, and it is one of Mondi’s largest plants. It is the biggest integrated pulp and paper mill in Slovakia.

“We were looking for a supplier that could deliver reliable, state-of-the-art technology,” says Peter Demčák, Operations Director, Mondi Ružomberok. “The main factor which led us to decide on Valmet was their technology and its flexibility, and how they could adapt the design of the machine for the product and quality we needed.”

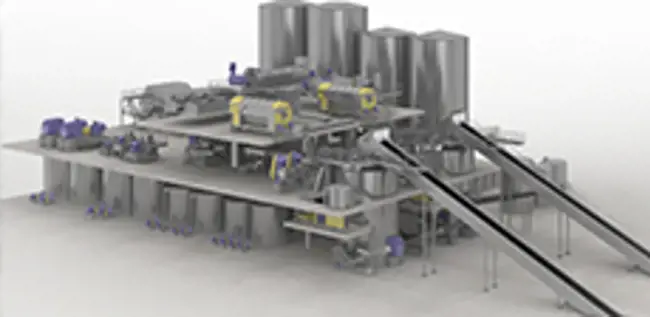

For the OCC line, the delivery included a complete OptiRefiber recycled fiberline, as well as the whole stock preparation line. The PM 19 delivery included a complete Valmet OptiConcept M containerboard line and an OptiWin Drum two-drum winder with Dual Unwind.

We were looking for a supplier that could deliver reliable, state-of-the-art technology.”

Pilot trials optimize the machine concept

Mondi’s new PM 19 machine produces a new containerboard grade, kraft top white, with a white virgin fiber top layer and a recycled fiber bottom layer. The challenge was to have proof for the concept, where the white top layer runs “on the bottom.” Valmet supported Mondi with pilot trials at their Paper Technology Center in Finland. “The experience with the pilot trials was excellent,” says Ľuboš Líška, Production Manager, PM 19, Mondi Ružomberok. “We tested the dewatering in the forming section and saw the behavior of paper properties with the Sleeve roll technology. We tried many adjustments. Quick results and new ideas for improving our product helped a lot.”

Several important technical solutions enable the machine to produce high-quality kraft top white. “It has a combination of a hybrid former on the print ply and a gap former on the back ply,” says Líška. “As well as three-nip press and size press concepts, there is a simple film press, which contributes well to strength properties.”

In describing the performance of the PM 19, Líška concludes: “From a runnability perspective, this paper machine is extraordinary. The paper machine has a big operational window and possibility to keep the paper on.”

The machine has an excellent design from a runnability perspective.”

Industrial Internet and automation solutions ensure successful start-up

To help Mondi start up both lines successfully, Valmet delivered the world’s first Virtual Paper Mill with interactive training modules and provided remote support for the start-up from the Valmet Performance Center. The Virtual Mill is an interactive digital design twin of the customer’s machinery and surrounding facilities. It can be used to train operators and maintenance workers, both before the initial start-up and during major shutdowns. “During the pandemic, we trained our operators on our virtual machine’s 3D model, so they were much more prepared and ready for the start-up,” says Demčák.

The delivery also included Valmet Advanced Process Controls (APC) with strength property optimization and on-demand expert support from the Valmet Performance Center. Advanced Process Controls are used to calculate and continuously optimize process parameters to ensure stable quality at the targeted level. “We have a virtual model for all three main parameters – SCT, burst and kheops – and all of them are working well,” says Demčák. “I am especially pleased that we developed the kheops measurement with Valmet, as this measures appearance and mottling.”

Valmet also delivered the full automation package, including Valmet DNA Distributed Control System (DCS) and a Valmet IQ Quality Management System. “The automation system is very easy to use,” says Marek Slamka, Automation Specialist, Mondi Ružomberok. “Having just one system gives us the opportunity to combine trends and analysis tools for different areas like QCS and DCS or QCS and MCS.”

Good performance from a successful project

With the new machine, Mondi can produce a completely new product, ProVantage Smartwhite, which is an alternative to white top kraftliner that has never previously been on the market. The Ružomberok team is very pleased with the machine’s performance.

Being well prepared is one of the keys to a successful start-up and a successful project. “We enjoyed good cooperation with Valmet, and we’ve been working as a single team, with a single target: a successful start-up,” says Demčák.

“For me, as the responsible person of production, a successful project means keeping the timeline and staying on target,” says Demčák. “The target is always to supply the customer with the paper they expect in the time that they expect it. And with PM 19, we achieved that goal. For me, that’s a successful project,” concludes Demčák.

Text: Peter Cura, Elsa Sinjaga