Innovative top forming unit boosts quality, capacity and dewatering

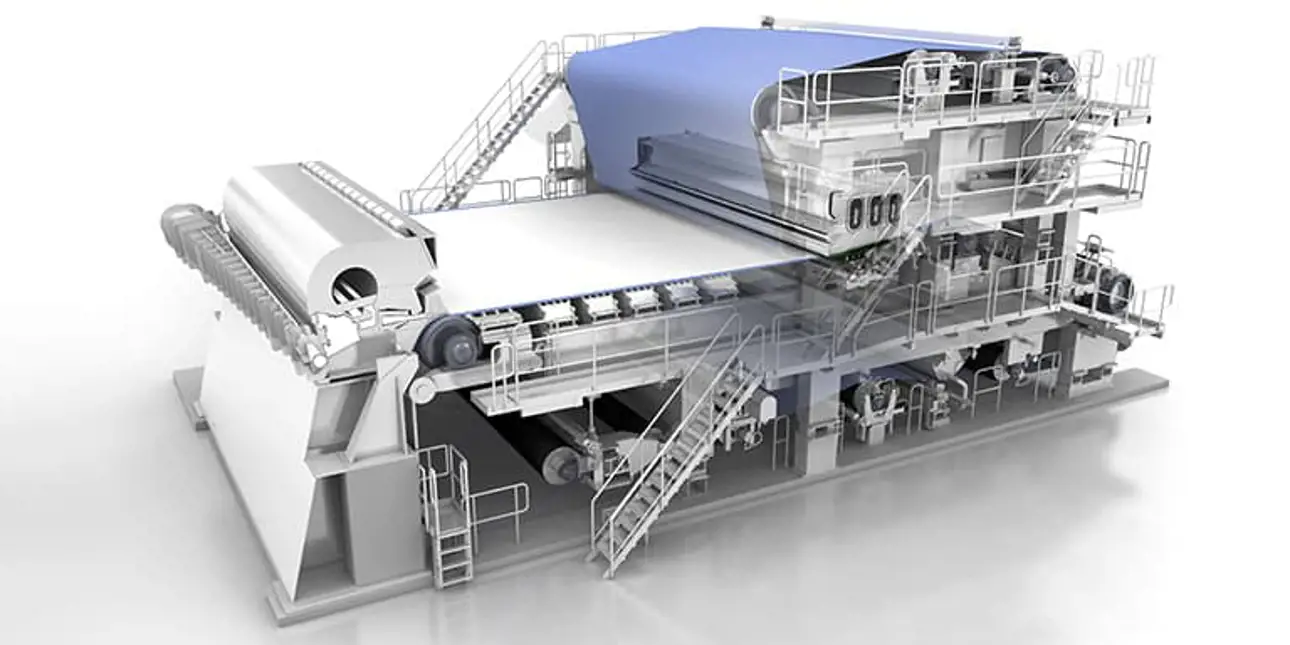

OptiFormer Hybrid with shoe and blade forming section

Valmet's proven solution for hybrid forming is OptiFormer Hybrid, a former equipped with shoe and blade technology. OptiFormer Hybrid utilizes unique VacuShoe technology to boost the output quality and capacity of new and rebuilt paper and board machines over a broad range of machine speeds and basis weights.

Easy operation within a wide operating window

Superior and controllable dewatering

Improved paper quality, especially the formation

Potential for fiber cost savings

High drainage capacity and forming section runnability with hybrid former

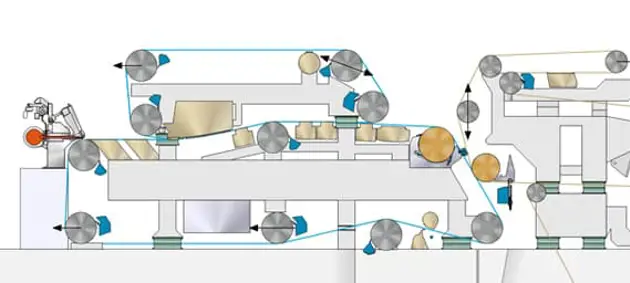

VacuShoe is a curved vacuum-assisted dewatering element that is mounted on the top side of the sheet. With VacuShoe technology, paper can be produced at greater speeds without running into drainage capacity limits. The water removal capacity of VacuShoe facilitates the use of lower headbox and top former inlet consistencies than earlier hybrid former solutions.

OptiFormer Hybrid with shoe and blade forming section allows machine speeds to be increased past the speed limits of conventional top former units. Good controllability, together with the ability to use a shorter forming table, also improves the runnability of the former.

OptiFormer Hybrid with shoe and blade technology was previously known as ValFormer.

OptiFormer Hybrid shoe blade forming technology has been applied with excellent results also in Fourdrinier rebuilds. An OptiFormer Hybrid rebuild can greatly increase output and end-product quality, and there is also great potential for fiber cost savings. This kind of rebuild offers a way to improve both capacity and quality, resulting in shorter payback time, for both paper and board machines.

Want to talk to our forming section experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact forming section expersSee the shoe and blade technology in action

The video displays the shoe and blade technology in Valmet forming sections with both paper and packaging grade applications. In addition, we show multiple different forming section layout options where shoe and blade technology has been used.

Looking for forming fabrics?

Valmet has constantly improved their forming fabric technology and created fabrics providing excellent runnability, high wear resistance, long running time, good paper profiles and good retention. Specialized forming fabric designs for packaging grades continue to improve drainage.

Read morePlanning a grade conversion?

The world is changing fast; the consumption of newsprint and printing paper is decreasing and the consumption of containerboards or cartonboards are increasing. An old paper machine can be updated with a grade conversion rebuild to produce more profitable products. Turn a new page for your paper machine with the help from Valmet.

Discover moreHow do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. But where do you start? Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Download e-bookExplore our latest board and paper press releases

- Jun 13, 2025Dr. Jin-Doo Kim awarded with a Medal for Extraordinary Achievement for decades-long work for promoting board and paper technologies

- May 26, 2025Valmet to supply a fifth Advantage tissue production line to Lila Group in Turkey

- May 21, 2025Valmet to supply a major paper machine rebuild to Sylvamo in North America

- Mar 27, 2025Successful start-up of Zhejiang Forest United Paper’s PM 6 production line

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China