Keeping machines in top condition

Valmet Condition and Runnability Monitoring

Valmet’s comprehensive services for condition and runnability monitoring include everything from audits to planning, analysis and diagnosis with expert specialist support. Our in-depth know-how helps you ensure board and paper, tissue, pulp as well as energy production applications run smoothly.

Improve machine safety - Avoid failures and operational risks by planning and executing maintenance safely

Increase process availability - Reduce unexpected and maintenance-related downtime with proactive analysis

Boost maintenance efficiency - Shorten maintenance time and reduce costs with the right skills and spare parts

Prevention drives productivity

Prevention of unexpected downtime is more than just avoiding production breaks and high repair costs. Improving equipment reliability and availability is about ensuring productivity. With our broad and deep knowledge of both systems and components, we can deliver everything required for true runnability monitoring.

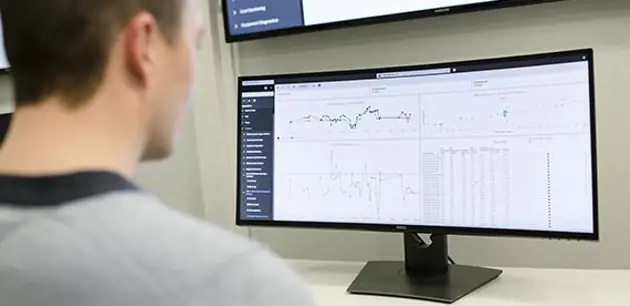

Our experts and advanced tools analyze and diagnose issues, remotely or on-site, across entire application processes. We take the standard elements of condition monitoring, such as vibration and lubrication monitoring, and assess how they impact process performance.

By analyzing vibrations and process performance, we can determine how interactions lead to possible interferences. With detailed insights, we ensure the components critical to product quality are in tune for optimal productivity.

From turnkey monitoring to targeted problem solving

Our services can be an integral turnkey function in your monitoring program or part of a targeted effort to resolve issues or improve performance. We can easily customize services to suit requirements according to location, application process area, or specific machinery.

System-wide services include leveraging Valmet online measurement solutions to pro-actively maintain system performance. We conduct system audits to identify improvement opportunities. Our experts can also help you plan and develop your condition monitoring methods and practices.

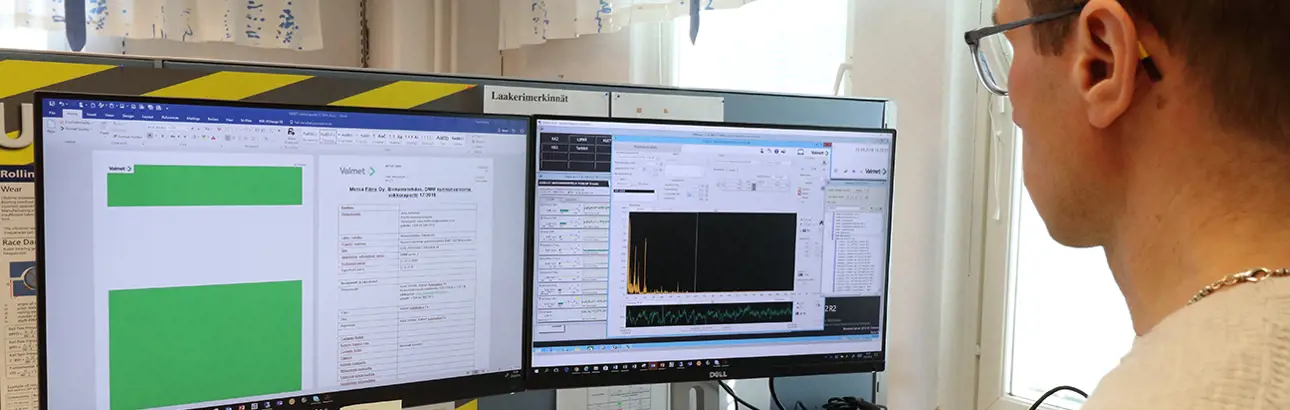

Our Analysis and Diagnosis service can be as simple as remote expert support for your condition monitoring organization, or Valmet can carry out regular online or periodical offline monitoring for you. Specialist Services include technical support for specific problems, such as bearing or gear wear, or full system maintenance using online vibration monitoring. For internal teams, we also offer a range of training services to help your operators carry out monitoring tasks themselves.

Our condition monitoring services:

- Condition Based Maintenance Audit

- Condition Monitoring Planning

- Analysis and Diagnosis

- Specialist Services

Condition monitoring offering