Maintenance development and outsourcing services for heat, power and gasification plants

Team collaboration to optimize processes and operations onsite for energy production

Whether you’re running an new or existing energy plant, the optimal target is to maximize reliability and optimize performance. To help you reach your targets, we work together for continuous success. In greenfield mills we can help to secure world class start-up curve and speed up the return of investment. At existing mills we can help customers to:

Reduce maintenance costs by 10-20%

Increase efficiency by 5-10%

Safe and sustainable maintenance operations

Let us walk you through how we helped our customer to reach their targets

This energy plant customer had challenges to secure world-class start-up curve, meet operation and maintenance targets and establish and train an operator- and maintenance team to become multiskilled powerplant operators.

Are you ready to succeed with us?

Our experts are here for you and ready to discuss your challenges. Answer a few questions and we will contact you shortly.

Contact usHow to maximize reliability and optimize performance with maintenance development and outsourcing services?

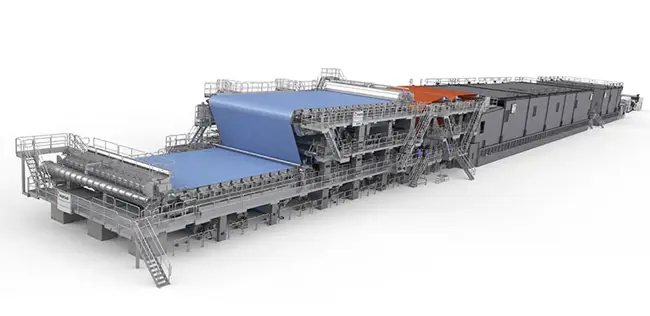

We are continuously challenging ourselves to develop our maintenance development and outsourcing services. The best results are achieved by working together. To help energy producers reach their targets, together we set-up a dream team with modern maintenance processes and mindset committed to safe and sustainable maintenance operations. A team ready to take on your site's everyday challenges. Reliable maintenance operations will make your energy plant run optimally throughout its lifecycle, allowing you to focus on your core business.

Maintenance development support to site maintenance organization

We continuously develop our maintenance procedures, our way to manage maintenance and new maintenance solutions to meet your needs. The team is connected to our global network of expertise 24/7.

Benefits with maintenance development for energy plants:

- Efficient and disturbance-free production

- Systematic and efficient way to operate

- Maintenance cost efficiency

- Less unplanned maintenance-related shuts

We see that our customers are facing challenges related to limited development resources, insufficient maintenance data at the plant, limited time, low availability due to many unplanned shutdowns or breaks and inefficient cost analyzing and planning.

All maintenance development services can be main portions inside the wider agreements like outsourcing, performance, maintenance, reliability, turn-key CMMS, etc.

70+

maintenance data deliveries

100+

maintenance audits delivered

Maintenance management services a systematic approach for more efficient operations

Maintenance operations agreements are the advanced cooperation we have with the customer. Our committed maintenance professionals provide maintenance management and technical support services for the customer.

Benefits of maintenance management services can be turnkey solutions for systematic and more efficient operations. Using Valmet’s knowhow on maintenance, process technology and automation, processes can be taken to the next level, whether outsourcing existing or new maintenance management operations.

Are you ready to succeed with us?

Our experts are here for you and ready to discuss your challenges. Answer a few questions and we will contact you shortly.

Contact usMaintenance outsourcing services to take on full responsibility of the energy plant's maintenance and workshop operations

With our maintenance outsourcing services we take full responsibility of the mill's maintenance and workshop operations, including inventory management on-site and the hiring of required maintenance personnel.

Benefits of outsourcing services include turnkey solutions for systematic and more efficient operations, allowing the mill to focus on its core business. Using Valmet’s knowhow on maintenance, process technology and automation, processes can be taken to the next level, whether outsourcing existing or new maintenance operations.

Why maintenance outsourcing services improves your productivity?

- Mills can focus on their core business

- Systematic and efficient operations

- Valmet's knowhow and expert services in use

Long-term collaboration to optimize maintenance costs and process availability with outsourcing agreements for existing energy plants

In the case of existing maintenance operations, an outsourcing process starts with a maintenance audit that covers both financial and operational aspects of the current maintenance operations. This study reveals the realistic development potential of the energy plant in terms of maintenance costs and process availability.

The typical scope of an outsourcing agreement covers:

- Daily maintenance and shutdowns

- Maintenance development

- Maintenance materials management

- Maintenance supplier network management

Establishment of maintenance for new energy plant

For new mills, the service scope includes setting up the organization and maintenance processes. This is always an extensive project and related planning should start already at the pre-engineering stage. The following issues need to be addressed before start-up:

- Collection of required technical data and documentation

- Creation of preventive and predictive maintenance plans

- Implementation of a Computerized Maintenance Management System (CMMS)

- Recruitment and training of maintenance personnel

- Set up of maintenance supplier network

- Set up of maintenance facilities, such as workshops and storage

- Purchase of maintenance tools and equipment

- Spare parts selection and procurement

Articles and references