Second generation bioethanol and biochemicals

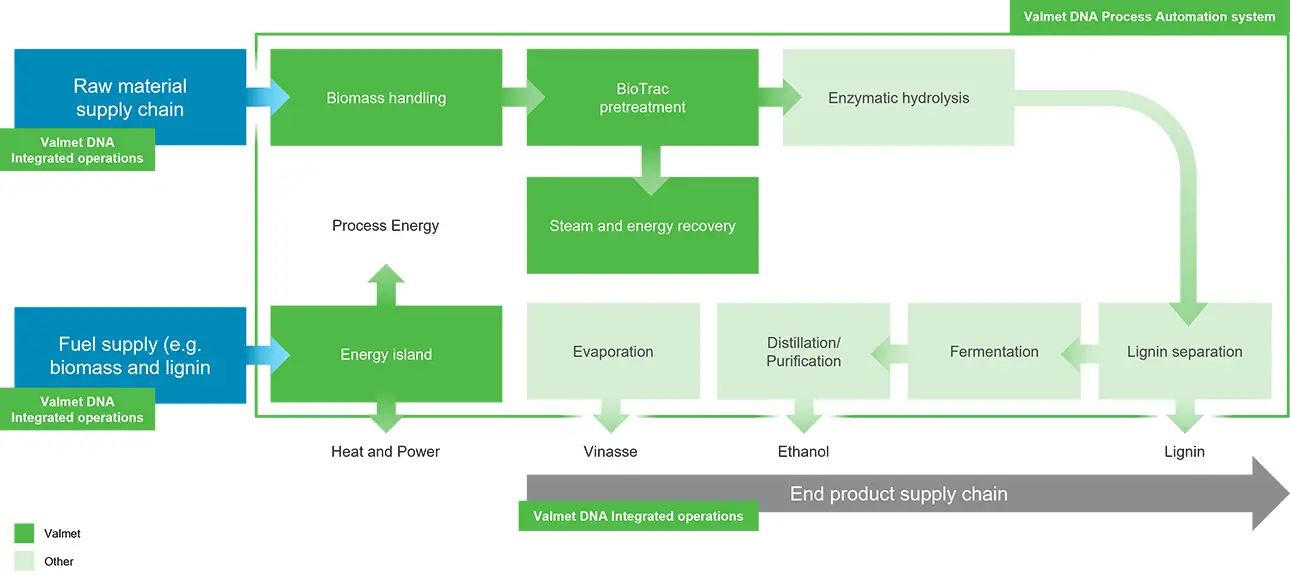

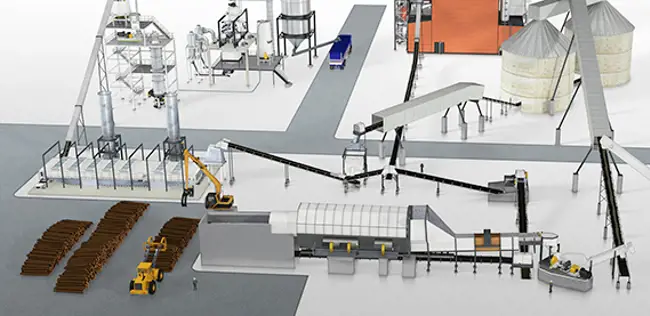

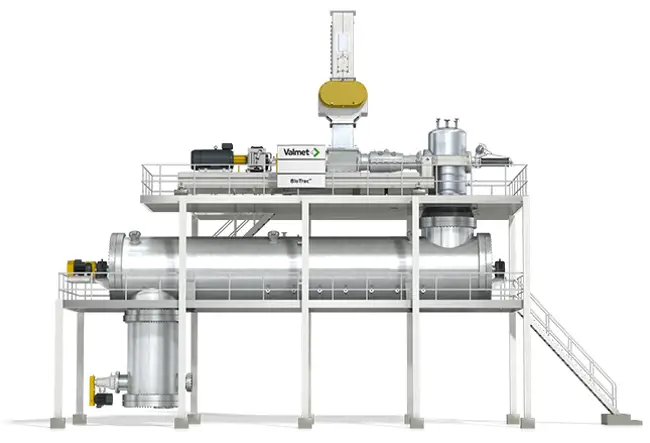

Valmet provides front-end technology for the production of second-generation bioethanol (2G ethanol) and biochemicals. 2G ethanol is a renewable biofuel that reduces the use of fossil-based petrol/reduces emissions of fossil carbon dioxide without interfering with food or feed production. Our technology can in the same manner be applied for production of biochemcials targeting to replace fossil-based alternatives used in production of for examples plastics.

1st generation bioethanol

Produced from sugar or starch produced by food crops (e.g. wheat, corn, sugar beet, sugar cane, etc).

2nd generation bioethanol

E.g. cellulosic ethanol is produced from agricultura residues (e.g. straw, corn stover), other lognocellulosic raw materials (e.g. wood chips) or energy crops(miscanthus, swithgrass, etc).

Valmet offering 2G ethanol, 2G sugar, biochemical

Our expertise is at your service

Our focus is to bring your performance forward. Get in touch with us through our website, or through your local Valmet office.

Contact us