Get the most out of your automation processes

Valmet Process Performance Services

Sustainable performance starts with your existing installation. Valmet Process Performance Services help you eliminate weak points and improve performance through process optimization and better automation control.

Increase production capacity while decreasing harmful emissions

Optimize end-product quality and reduce variability

Reduce raw material and maintenance costs

Identify all the opportunities for improvement

When performance improvement is on the agenda, the Valmet Performance Study service is a good place to start. The study evaluates the improvement potential in your processes using Valmet’s advanced measuring capabilities.

The study can include just data gathering, or you can get full analysis and action planning with benefits calculations. Once opportunities are identified, we can craft solutions to help you meet precise goals.

Gain full control of your automation

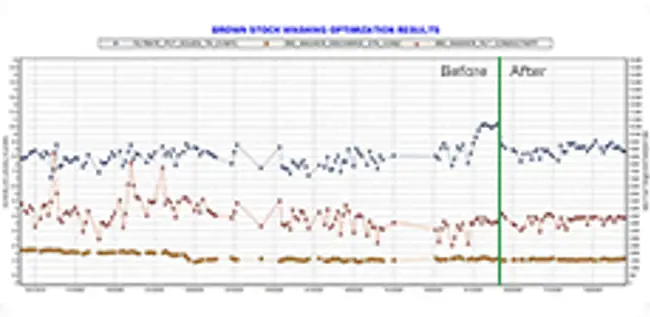

Our process performance work centers around Valmet Process Optimization services, covering Analysis and Diagnosis, Performance Optimization and Control Performance. By stabilizing process variability and improving performance, we help you reduce raw material usage and achieve greater overall sustainability.

Process optimization services provide early warnings of potential process upsets with proposals for corrective actions. We help properly tune control loops for higher efficiency and better end-product quality. Regular monitoring and performance control also provides insights and suggestions for longer-term process development opportunities.

Trusted expertise that makes the difference

Our customer focus and commitment to continuous improvement underly all Valmet Process Performance services. We use our process and control know-how, add deep data analysis experience and tools, and help you identify the best actions with the highest returns.

If you need additional resources or special skills to carry out process performance actions, we can also provide on-site expert support. With our On-Site Expert service, you can be certain to have continuously available assistance for mutually agreed assignments and targets. Valmet’s on-site personnel are fully supported by our global network of automation experts.

Process Performance services

- Performance Study

- Process Optimization

- Analysis and Diagnosis Services

- Performance Optimization

- Control Performance

- On-Site Expert