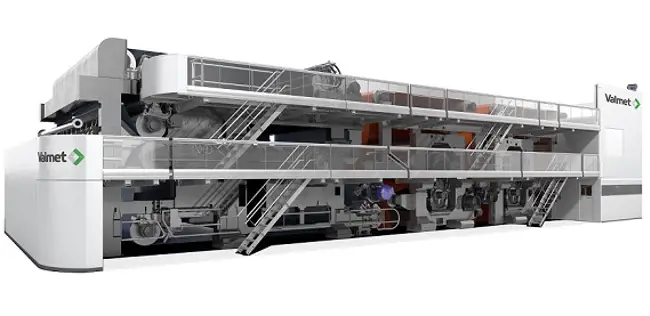

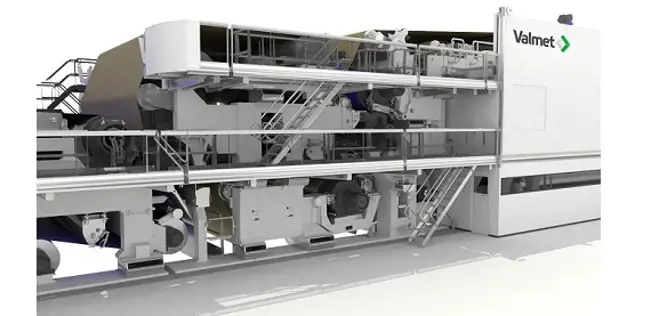

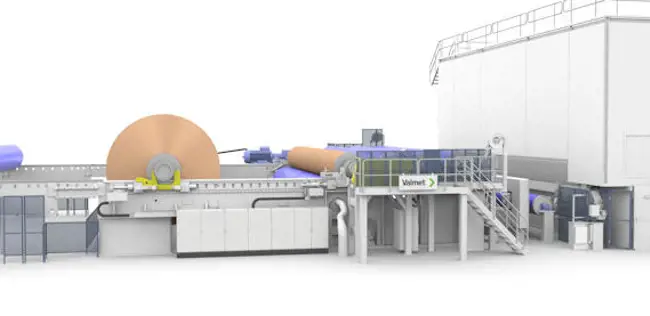

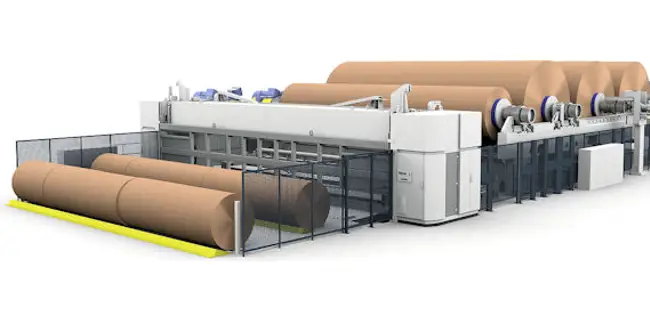

Board and paper machines

Did you know that 40% of the paper and board in the world is produced with Valmet's paper machines? We value the possibility of staying in close collaboration with our customers so that we can continuously develop new products and papermaking processes that meet customers' needs in energy efficiency or using raw materials more efficiently. By choosing original Valmet machinery and products, you guarantee that your operations – and profit – stay up and running. Uninterrupted.

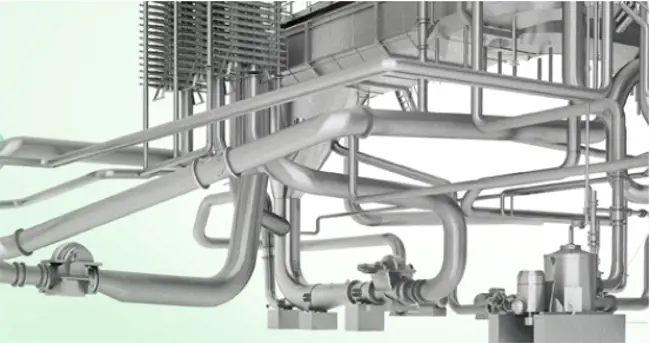

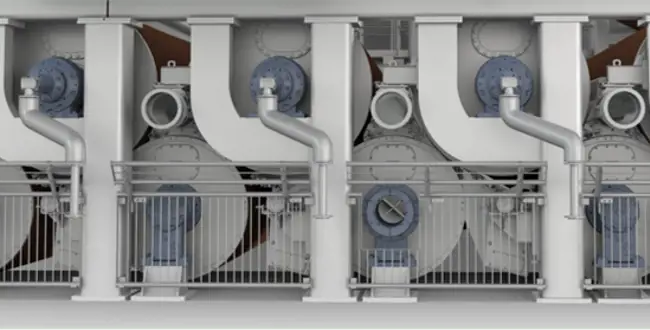

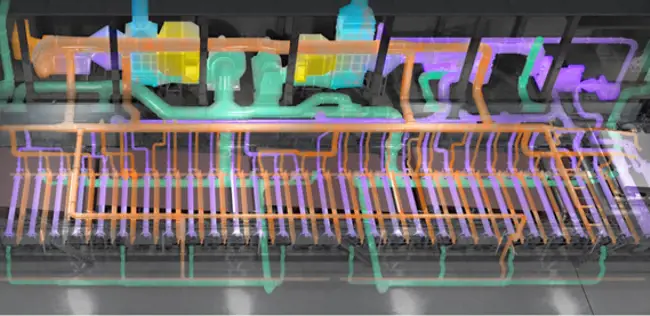

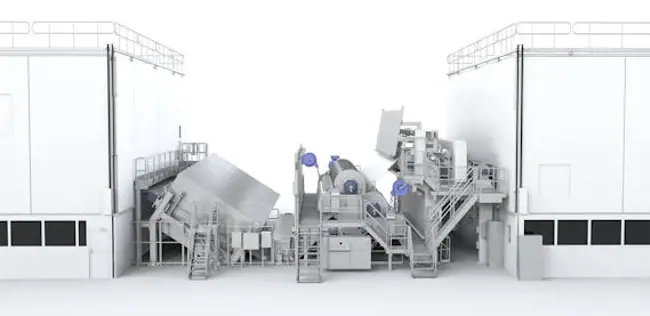

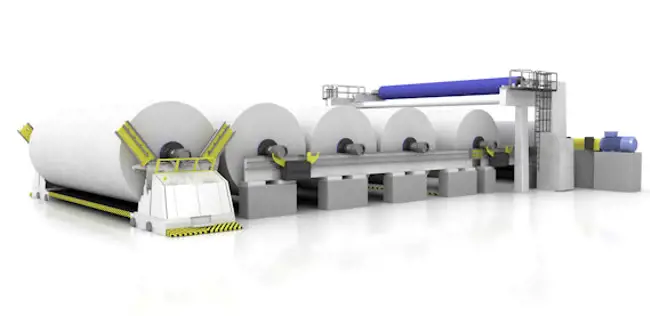

At Valmet we have the expertise and technology to understand your production-specific papermaking process, from furnish preparation to paper and baseboard making, sizing, coating, coating drying, calendering, reeling, winding and wrapping needs. Our experienced and skilled people support and guide you from initial planning to the project phase, through commissioning and start-up to continuous production – throughout the entire lifecycle of the paper machine line.

Want to talk to our board & paper experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our experts

Explore our latest board and paper press releases

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States

- Jul 8, 2024Discover Valmet MTC Wizard at Tissue Innovation Days 2024: the latest technology enhances Client benefits in Tissue Folding

- Jul 2, 2024Valmet to supply a high-capacity winder to Wuzhou Special Paper in China

- Jun 26, 2024Valmet to supply both a papermaking line and a paper machine rebuild to a customer in Asia-Pacific

- Jun 25, 2024Valmet to deliver a tissue machine to Andhra Paper in India

- Jun 19, 2024Valmet receives the second order of converting lines to Metsä Tissue in Mariestad, Sweden

- Jun 13, 2024Valmet and Flootech enter partnership to advance water treatment for the board, paper and tissue industry

- May 30, 2024Valmet enters joint venture with Körber to advance the digital offering to the tissue industry

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China