Pulp cleaning

Are you looking to remove unwanted particles such as sand, glass, metal, plastic, and polystyrene from your pulp?

Increased fiber accept

Improved runnability

Industry-leading technology

Optimal impurity removal

Expertise in Cleaning

Pulp and paper mills invest in hydrocyclone plants to improve efficiency and drive performance. Our global team of experts has vast experience optimizing hydrocyclone solutions for an installed base that includes thousands of hydrocyclone systems worldwide. Whether your goal includes removing heavy or light weight impurities or recovering fiber/thickening stock, a Valmet expert is close to you with solutions and support.

Valmet’s hydrocyclone technology removes unwanted particles such as sand, glass, metal, inks, certain unwanted organics, plastics, wax, and Styrofoam down to 50 microns. The result is cleaner pulp, better quality products, and the protection of process equipment downstream.

Optimize your cleaning performance

Lets work together to increase your fiber retention and reduce plugging.

Contact us

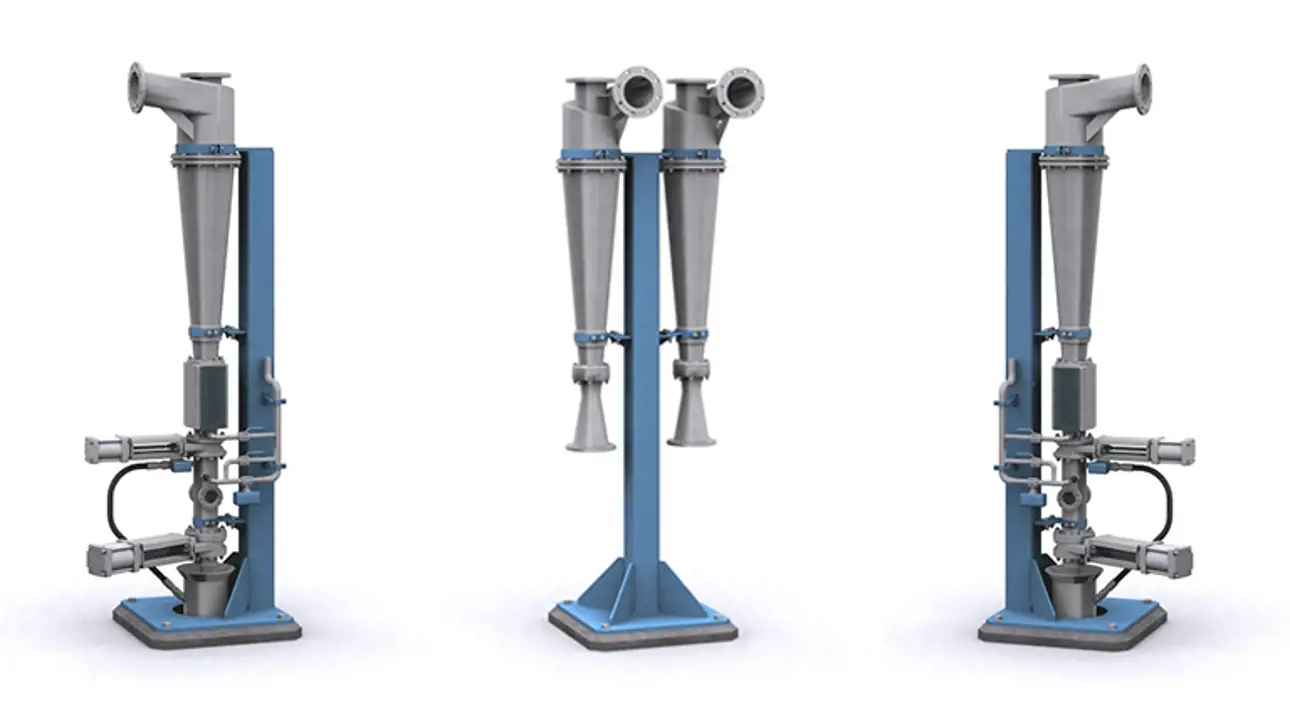

Low consistency hydrocyclones

Low consistency cleaning involves removal of fine debris such as sand, ink, specks of bark, wax or bits of Styrofoam. The typical low density hydrocyclone operates at 1% consistency and is available in different configurations depending on the specific gravity of the unwanted particles.

Explore our low consistency hydrocyclones |

| Valmet low consistency hydrocyclones |

| Forward hydrocyclones |

| Reverse flow hydrocyclones |

| Parallel flow hydrocyclones |

| Combination hydrocyclones |

Medium consistency hydrocyclones

Valmet offers medium consistency hydrocyclone technology that is designed to optimize efficiency. Typical medium consistency cleaning applications involve sand removal at approximately 2% consistency.

Explore our medium consistency hydrocyclones |

| Valmet medium consistency hydrocyclones |

| Valmet Twister Hydrocyclone |

| Valmet Hydrocyclone A1600 |

High Consistency Cleaners

Valmet offers high consistency cleaning solutions that meet requirements for various pulps with applications for both single-stage and two-stage systems.

Explore our high consistency hydrocyclones |

| Valmet high consistency hydrocyclones |

| Valmet Hydrocyclone A3000 / A5000 |

| Valmet Hydrocyclone HC |

Valmet Green Line Cleaners

Developed in cooperation with an industry-leading plastic manufacturer, Valmet Green Line Cleaner technology was produced using a carbon-neutral plastic material.

Learn more

Hydrocyclone Optimization

Valmet offers high consistency cleaning solutions that meet requirements for various pulps with applications for both single-stage and two-stage systems.

Improve your pulp cleaning |

| 5 important parameters for pulp cleaner control |

| Improving pulp cleaning performance |

| Hydrocyclone optimization |