Innovative solutions and proven technology

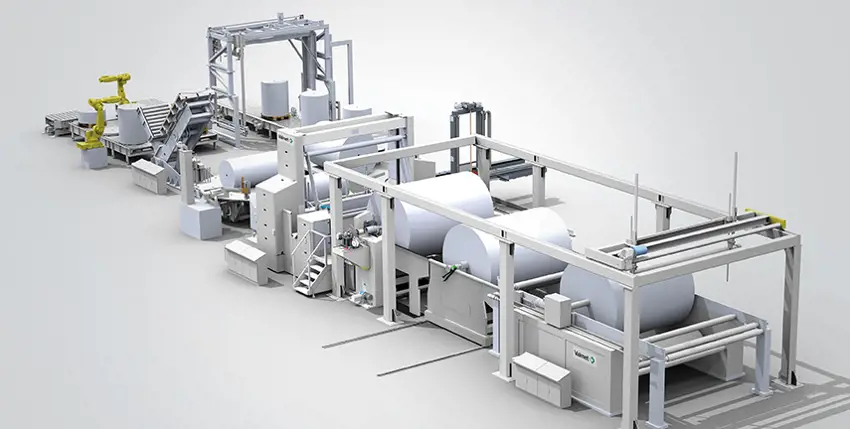

Valmet's nonwovens rewinding lines

With the goal of helping nonwovens producers achieve their desired end results, Valmet has developed a winding and rewinding concept that we term No-Stress

FLEXIBILITY

A large scope of machines that are adaptable and easy to operate.

QUALITY

Preservation of the bulk and improved absorbency. State-of-the art equipments to control properties and quality of the nonwovens products.

PERFORMANCE

High efficiency and production capacity

No-Stress with electromechanical technology

When producing quality nonwoven products it is important to effectively unwind, process, rewind and prepare the new parent reel for delivery to the floor or next stage of the converting process. All this needs to be done in a manner that imparts minimal stress to the web and maximizes the preservation of built in product characteristics.

Valmet has developed a winding and rewinding concept that involves several sections of

the end line: Winder, Slitting/Rewinder, Finished Reel Removal, Handling/Packaging

system and all associated Automation.

Preserving material characteristics

The electromechanical winders are equipped with a tension control system, assuring big dimension rolls with high density, preserving the material characteristics. The proven control system and algorithm to manage the relieving action have been verified and tested in numerous installations.

Rewinder stations from Valmet utilize Electromechanical chucks, carriages and the relieving system for rider rolls. The control system and algorithm to manage relieving action are developed by Valmet specialists. These components are extremely precise and effective, especially on large diameter and high weight finished reels, and they assure perfect automatic control of finished reel density.

An exclusive preview

At the NonWoEvent, Valmet presented the new In-Line Winder Rollite NW1-IN, which is the perfect summary of the electromechanical technology applied to material careness.

Read the articlePulling instead of pushing

For Finished Reel Removal, Valmet developed an innovative system that removes the finished reels from the winding position when the target diameter is reached: “Pulling” the reels out rather than “Pushing” them out.

This system is also Electromechanical and it gently positions the finished reel on a Shuttle that performs all the operations related to an automatic reel change: web cross cut, loading of new cores into winding position and delivery of the finished reel sets to the floor or other handling equipment.

Welcome to run your test trials

Rollite NW1-IN is now installed in the Pescia facilities, Italy. All the features of the machine will can be directly tested during dedicated running trials

Get in touch

Fully integrated automation solutions

Valmet DNA automation system gives you complete control of all your processes and provides user experience and transparency that go far beyond traditional automation systems. Valmet DNA can be applied for process controls, machine controls, drive controls, and quality controls. Information management is an integrated part of the platform along with mechanical and field device condition monitoring. The single system architecture saves on both costs and effort while ensuring open growth for your future challenges.