Microfibrillated Cellulose

Allows for lightweighting

Increased strength

- Bond

- Burst

- CMT

- SCT

- Tensile

Increased surface smoothness

Improved barrier properties

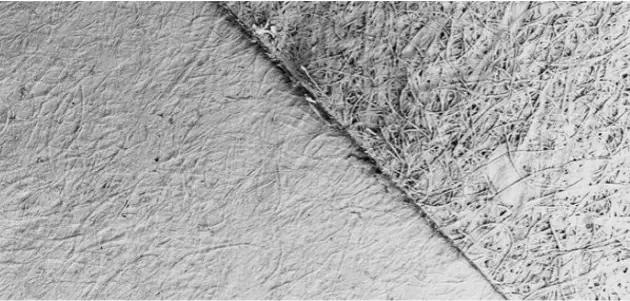

Microfibrillated Cellulose (MFC) is a natural material made up of cellulose fibrils that have been separated from a source, such as wood pulp. MFC fibers bond together and create strength, that when added to the paper-making process, can produce a wide range of benefits including increased tensile strength, improved barrier properties, smoother surfaces, and more.

Leadership in MFC Technology, Research & Development

Valmet is taking a leading role in expanding the role that MFC can play in the pulp and paper industry. From R&D and pilot trials to proven tools for MFC production and innovative solutions for applying MFC to the wet end of the paper machine, Valmet is the technology partner you can trust to help you realize the benefits of MFC.

A renewable, low cost resource

Are you looking for an environmentally responsible way to increase the ink absorbency, porosity, and smoothness of your paper grades?

Contact usMFC PRODUCTION AND APPLICATION

Valmet has pioneered a unique, refiner-based technology for MFC production. The production process combines advanced refiner and plate technology with an innovative control system designed to maximize production efficiency.

Valmet MFC can use disk or conical refining technology to produce MFC in either a batch or continuous refining process. Valmet MFC can be used for pilot trials using a trial skid that is available to rent.