VII for Production Capacity for energy

Are you using the full production potential of your power plant? Valmet’s Industrial Internet for Production Capacity is a solution for maximizing and minimizing the boiler load and thus increasing your plant flexibility and profitability. Discover your improvement potential with the help of our process expertise.

Real-time follow-up of production capacity remotely

Using cheapest fuel mix

Reduction of heat and electricity production cost

Maximum use of the most cost-efficient power production in real-time

- Operator guidance

- Automatic with advance process controls

Enables running the minimum load during low demand season

Production Capacity for energy

There are three key solutions to increase your annual production capacity.

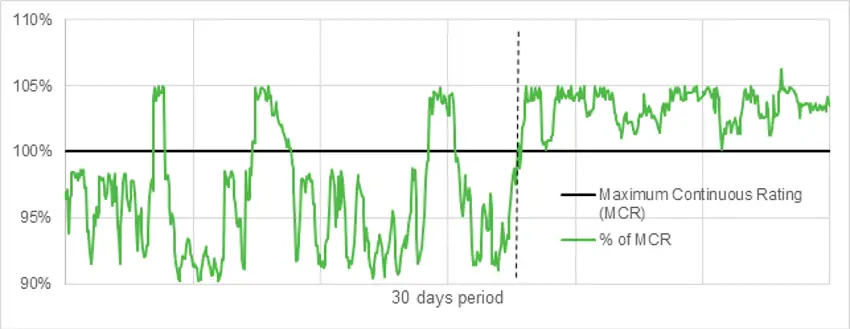

1) Operating at maximum boiler load without production limits

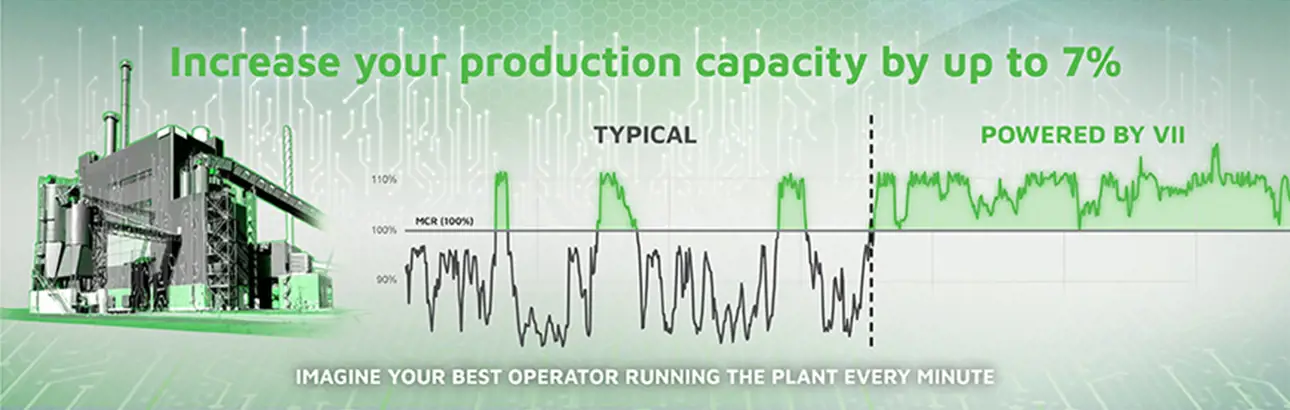

With Valmet’s Industrial Internet (VII) for Production Capacity, you can increase your maximum electricity/heat production capacity by up to 7% in your current process. The solution is based on process bottleneck analyses and operating against the first limiting factor using process knowledge.

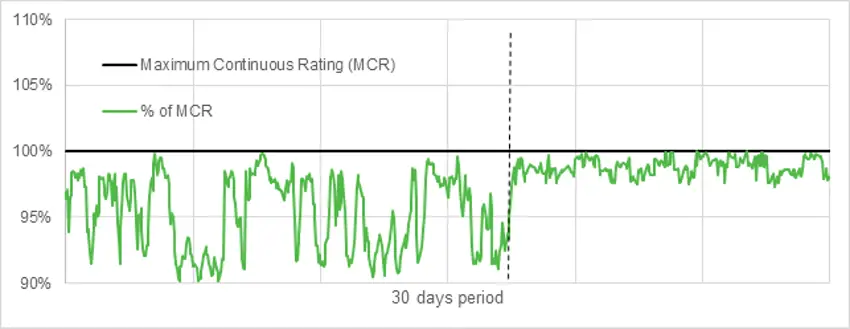

2) Operating at maximum boiler load within production limits

You can increase your production capacity, even with production capacity limitations, for example, in a case where electricity production has been limited to 50 MWe. A production capacity increase of up to 2.5% in the current process can be achieved by stabilizing the load and continuously operating the plant close to its operating limits.

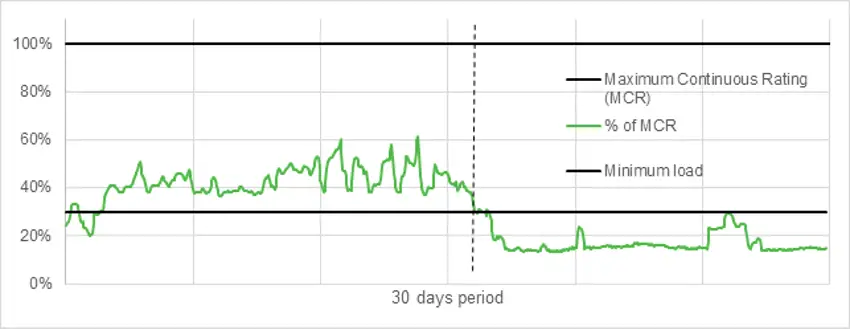

3) Operating at minimum boiler load

A decrease of up to 30% in minimum load can be achieved in low-demand events. It is possible to ensure more operational hours at the plant as well as decrease the amount of condensed heat and unnecessary shutdowns. The solution is based on process bottleneck analyses and operating against the first limiting factor using process knowledge.

The solution can be implemented as an operator advisory or automatized with advanced process controls. Further capacity modifications are possible through Valmet’s modernizations and upgrades with the help of our process expertise.

The payback of the production capacity increase varies case by case. Contact us to find out the improvement potential of your plant in its existing conditions.

Applications and services included in VII for Production Capacity solution

Performance Center |

|

Customer Portal |

|

Contact us for more information

Want to learn more about Valmet Industrial Internet (VII) offerings for energy? Contact us via link below and get in touch with our experts.

Contact us