Bark handling

Turn your bark into useful energy

The bark from the debarking process can be transformed into useful energy in a mill's power plant. The energy value is dependent on the dry content of the bark. Valmet has supplied several hundred bark presses, systems and equipment for handling and storage of bark worldwide. Equipment like: Wood saver wood recovery systems, Bark shredders, Bark crushers, Disc scalpers, Bark presses, Belt dryers, Receiving pockets, Bark silos and Bark stockpiling and stackers.

Low maintenance cost

Low operational cost

Valmet Biomass Chipper - Chipper for stringy bark

The Valmet Biomass Chipper DPC is designed for cutting stringy bark and other wood residues when conventional crushing is not enough. High capacity and innovative design allow feeding and chipping of large irregular volumes of material with high efficiency and productivity. Biomass Chipper cuts stringy bark into optimally sized particles with excellent cutting performance. Horizontal feeding ensures safe and trouble-free operation.

Valmet Bark Hog - Gravity feed crusher for stringy bark

The Bark hog is a compact size equipment designed to cut/crush bark and other wood-based materials. It is specially designed for spruce, acacia and eucalyptus species.

Valmet Bark Shredder - Turning your bark into perfect size

The Bark Shredder is designed to reduce bark into optimally sized particles, ready for various applications. The shredder successfully combines high capacity, excellent shredding performance and space-saving design.

The design incorporates simple robust construction, a one-piece fabricated frame, vertical rotor, large in-feed opening and centrifugal discharge. The rotor knives are pivoted to avoid damage by foreign particles such as small stones and metal pieces occasionally found in the bark.

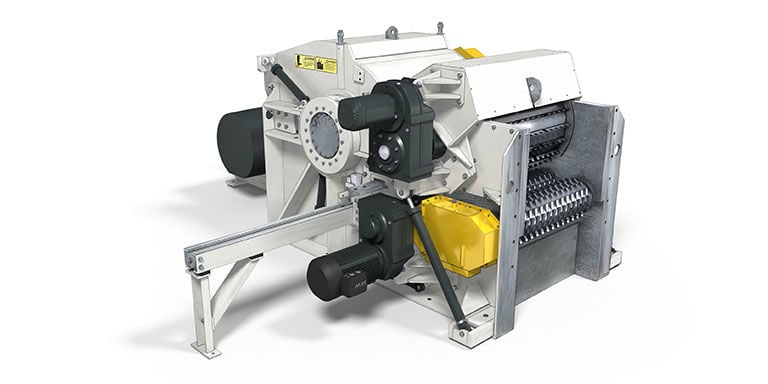

Valmet Bark Crusher

The Valmet Bark Crusher is designed to reduce bark into optimally sized particles, ready for further processing. The crusher combines high capacity with excellent crushing performance.

Bark is fed through a feed chute into the crusher. The horizontal rotor is equipped with pivoted hammers attached to the shafts. While rotating, the hammers crush the bark through the bottom grate. The fraction size of the crushed bark can be changed by adjusting the size of the hole of the bottom grate.

Valmet Wood Saver - Maximize wood-usage efficiency

Valmet Wood Saver is a special roll conveyor system designed to maximize wood-usage efficiency in debarking lines. The system saves wood by separating usable wood pieces from the bark line and returning the recovered wood back to the process, instead of burning them as waste together with the bark. Wood saver can also be installed in existing lines to increase the wood-raw material yield of the mill.

Simple construction

The construction of Wood saver is simple and functional. The recovery system consists of a separating roll conveyor, a chute for bark and debris, and an adjustable inclined conveyor for stone removal. Stone removal enables the mill to minimize the damage and wear of the bark crusher and its knives.

Valmet Bark Press - When high dry content matters

Valmet Bark Press is a reliable solution for transforming bark into a valuable energy source for pulp mills. Maximum bark dryness is achieved through efficient water removal and the highest capacity and dry content available on the market.

Individually moving pressing bars, efficient water removal, and optimal pressing time guarantee the highest possible dry content. Pressing time is automatically maximized according to the incoming bark flow. Water is removed through perforated plates on both sides of the machine.

Valmet Bark Press can withstand foreign objects, like stones, making it the only self-protecting bark press. The combination of unique technology and non-plugging design ensures smooth and reliable operation.

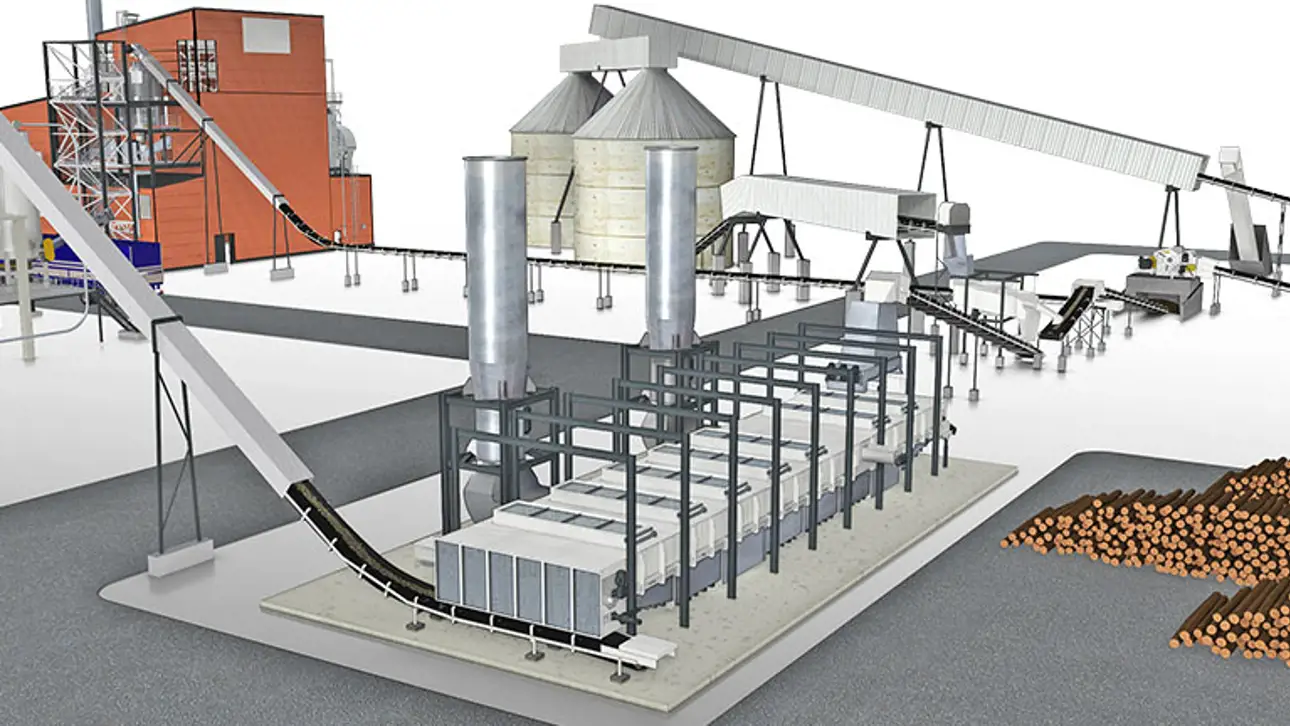

Storage systems for bark, biomass and chips

Valmet offers several storage and reclaimer solutions for chip, bark and biomass handling to meet diverse customer needs. These storage systems are essential for ensuring the optimal supply of materials to the processing operations.

-

Silos with rotary reclaimers

-

Storages with traversing reclaimers

Biomass drying

Valmet Belt Dryer offers low temperature drying for biomass, such as bark, forest residue, sawdust and bagasse. Dried biomass can be utilized as a valuable energy source in gasification processes, pelletizing and power boilers.

The reliable technology of the belt dryer ensures high dryness of the end material. It is easy to maintain and handle. The dryer utilizes secondary heat – no primary energy is needed.

Our expertise is at your service

We at Valmet are committed to moving our customers performance forward and ensure smooth, disruption-free operation, supporting you all the way.

Contact us