Valmet reeling

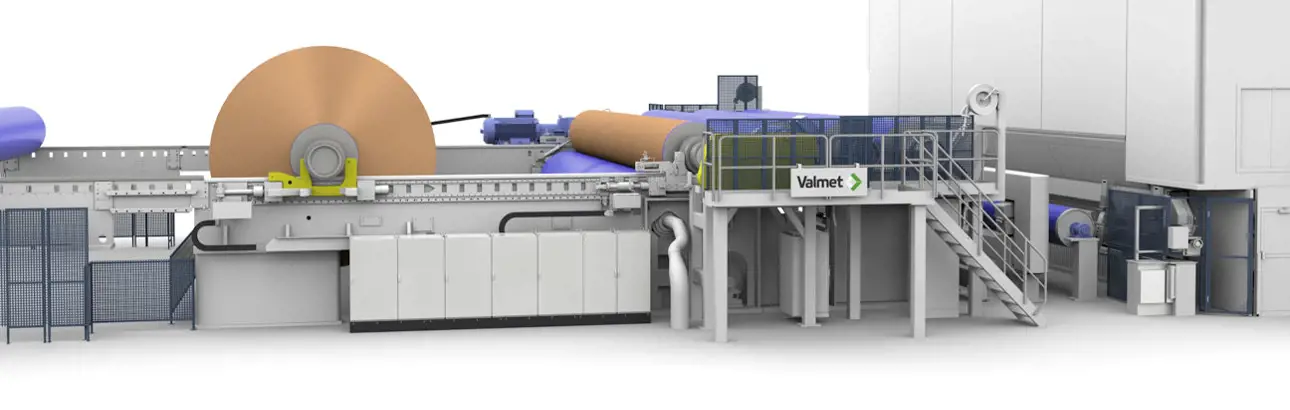

Improving production efficiency and line capacity

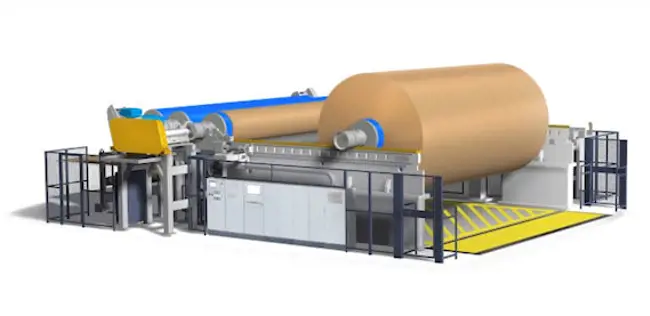

There is usually clear potential for improving production efficiency and line capacity in the finishing area. By letting Valmet help you in selecting the right reel for your grade, machine speed and web width, you can make full use of this potential. Valmet provides all paper and boardmakers with a wide range of reels to match their specific needs and various reeling challenges.

Discover Valmet reeling solutions

Get to know our two reeling product families: OptiReel reeling soluctions and IntelliReel reeling solutions. Click on the links below to read and find out more on our reeling solutions.

Reeling process and reeling parameters

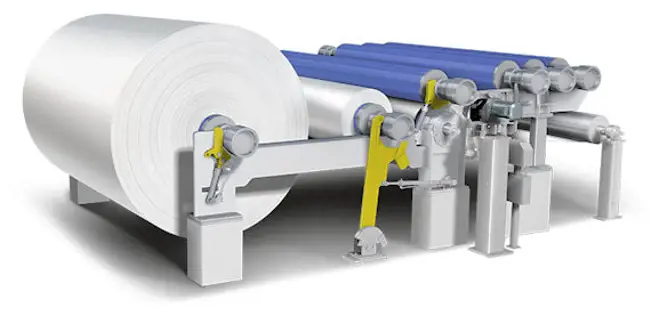

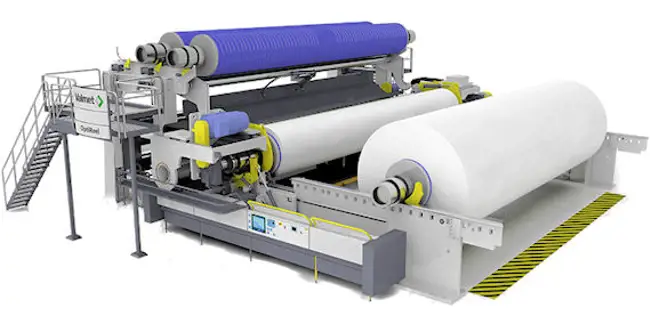

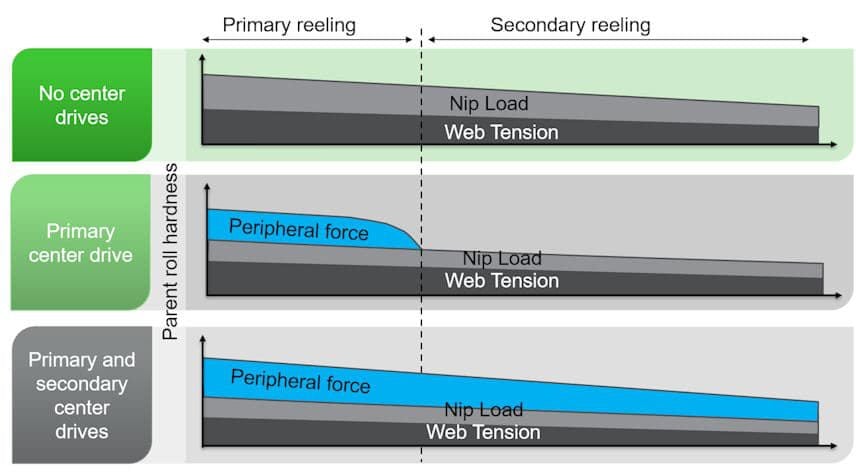

Reeling process becomes more demanding if the operating speed and reeling width are high, parent roll diameter is big and/or the paper or board grade requires more sensitive reeling. With the level of difficulty in reeling in mind, the reel types can be divided into two groups. Depending on the reeling process conditions, there are either reels without center drives or reels with center drives.

Reels without center drives are ideal for reeling required by grades and operations with less demanding reeling conditions. Reels with primary or primary and secondary center drives are aimed at the more challenging grades and high-speed production lines typically with online calendering and/or coating.

Parent roll hardness is directly affected by the center drives

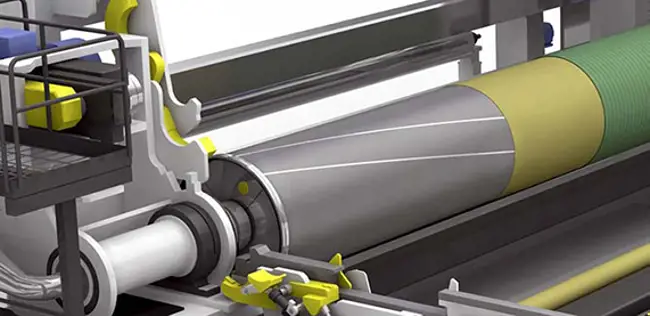

Bulk-saving reeling and winding

Reeling and winding are the two steps in the boardmaking process where the bulk of produced board can be either preserved or ruined. Nip loads that are too high are the main reasons for losing bulk. Valmet’s combination of bulk-saving reeling and winding are essential for e.g. coated board makers.

Valmet's center-driven reels – precise load control and use of center drives minimize bulk loss and the uniques OptiWin Belt – the ultimate winder for FBB, nip loads are less than 50% compared to a two-drum winder.

The total bulk saving potential is up to 4% with a combination of OptiReel center-driven reeling and OptiWin Belt winding.

Want to talk to our reeling experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsInterested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsHow to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookLearn more about the services and automation solutions for reels

Explore our latest board and paper press releases

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States

- Jul 8, 2024Discover Valmet MTC Wizard at Tissue Innovation Days 2024: the latest technology enhances Client benefits in Tissue Folding

- Jul 2, 2024Valmet to supply a high-capacity winder to Wuzhou Special Paper in China

- Jun 26, 2024Valmet to supply both a papermaking line and a paper machine rebuild to a customer in Asia-Pacific

- Jun 25, 2024Valmet to deliver a tissue machine to Andhra Paper in India

- Jun 19, 2024Valmet receives the second order of converting lines to Metsä Tissue in Mariestad, Sweden

- Jun 13, 2024Valmet and Flootech enter partnership to advance water treatment for the board, paper and tissue industry

- May 30, 2024Valmet enters joint venture with Körber to advance the digital offering to the tissue industry

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China