Premium performance for premium quality products

Valmet ThruAir Bonding

All Valmet ThruAir® bonders are designed with proven results and using one of our system models that have been tailored to meet the specific needs of the wide range of nonwovens applications.

Flexibility for superior quality

Valmet is the leader in through air technology; manufacturing rotary and flatbed Thru-Air systems for a full range of products. Thanks to our air flow and temperature distribution system designs, through air systems from Valmet provide the highest thermal efficiency and the lowest temperature and through air velocity variation in the industry. Machine speed, temperature, and air speed through the sheet are easily regulated, optimizing the drying process for superior quality of the final product.

We look forward to talking with you about how partnering with Valmet can move your nonwovens production forward!

Put quality first with the ThruAir Bonder

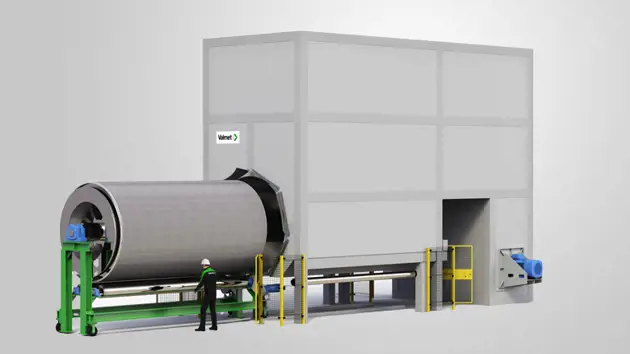

Nonwoven web producers now have an opportunity to invest in cost competitive equipment without compromising production quality. The Valmet ThruAir Bonder is a high-performance, cost-effective solution for producing premium quality nonwovens products.

Valmet has been supplying high-performance bonders since 1968; the latest design is derived from Valmet’s years of experience in through-air bonding and is designed to provide maximum value to the producer.

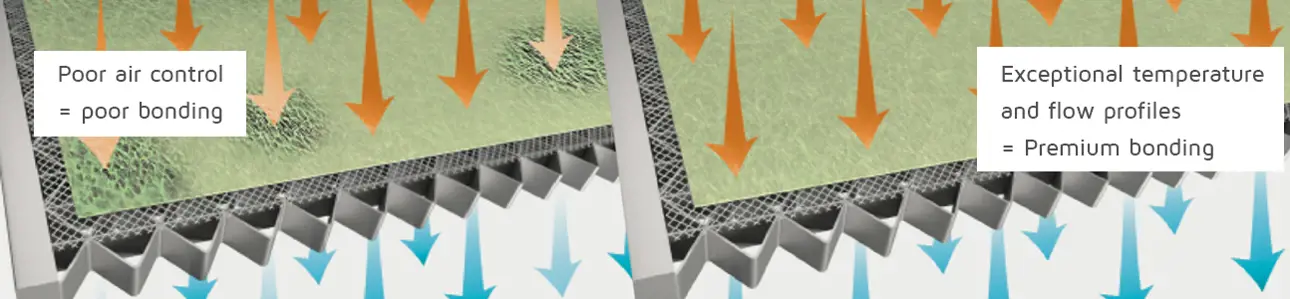

The Valmet ThruAir Bonder allows for premium bonding because of the exceptional temperature and flow profiles. It has a compact size which enables efficient space utilization. The roll-out design allows for easy and accessible maintenance as safety is always a priority.

Further, the Bonder is designed to support carbon neutral operation by accepting alternate heat sources.

Explore the new ThruAir Bonder

With this invention, we can now offer the opportunity to make premium grade products at a competitive cost, which in turn can lead to an increased market value for you as a nonwoven web producer.

BrochureHONEYCOMB® THRU-AIR thermal bonding

Valmet designs systems to meet all your thermal bonding needs. The revolutionary design of the HONEYCOMB ROLL, with 96% open area, is the heart of Valmet's advantage. With diameters ranging from 16 ft. (4.9 M) down to 12 in. (0.3 M) and encompassing applications from drying and hydro-entanglement to tensioning and web transfer, our custom designed shell construction meets the most demanding process requirements.

Learn more about the Valmet HONEYCOMB THRU-AIR thermal bonding systems