Valmet forming sections

High efficiency and excellent runnability

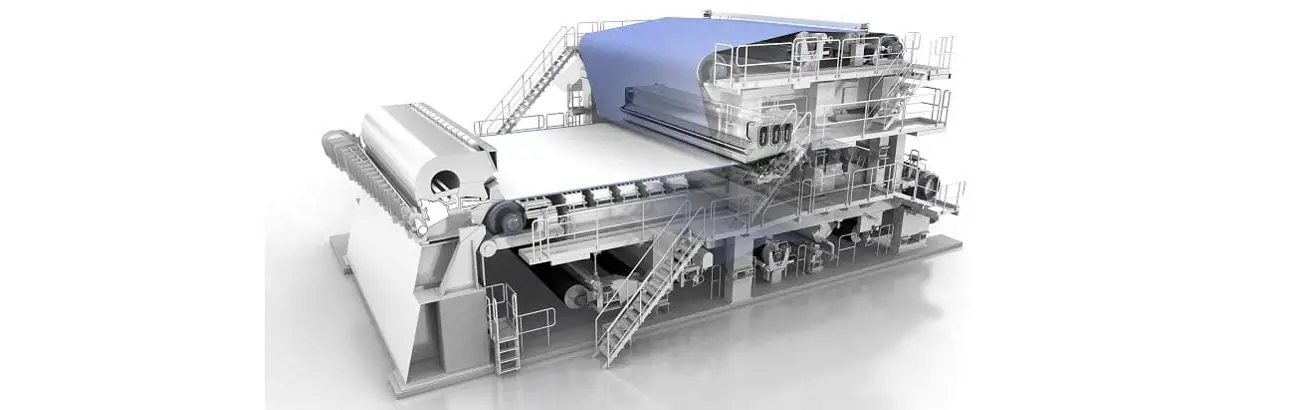

Valmet provides a comprehensive range of paper machine forming section applications for the varying requirements of different board and paper grades and speed ranges. The forming section concepts include solutions for gap forming, hybrid forming and Fourdrinier applications which can be used for new line installations and rebuilds alike.

Discover Valmet forming section solutions

Get to know our forming section product family OptiFormer forming sections. Click on the link below to read and find out more.

Wet end pilot trials for forming sections

We offer the opportunity to experiment and develop paper and board products and processes at Valmet Paper Technology Center without having to put your own production on hold. This is very cost-efficient compared to expensive tests in your own production. You can follow the activities in the trials on site or remotely through live streaming cameras.

Valmet Paper Technology Center provides the world's most comprehensive offering of testing and piloting services to paper and board manufacturers worldwide. Our pilot facilities have the entire process covered, from stock preparation to coatings and everything between, providing customers with excellent service and reliable results to support investment decisions.

Wet end forming section rebuilds

Rebuilding a paper or board machine, or a section of it, can improve the competitiveness of your business and your processes. But where do you start? Over the years, we have gathered plenty of experience and expertise in rebuilding all kinds of machines. We asked our experts to provide tips, advice and industry insight to help you demystify the rebuild process and created a practical guide book.

Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Want to talk to our experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsLearn more about OptiFormer forming sections

OptiFormer product family provides flexible forming solutions for all board and paper grades and a broad range of machine speeds, widths and capacities. OptiFormer forming sections provide the end product quality you need with highly efficient water removal, excellent runnability, and cleanliness.

OptiFormer forming section concepts include solutions for gap forming, hybrid forming and Fourdrinier applications, which can be used for new line installations and rebuilds alike.

Planning a grade conversion?

The world is changing fast; the consumption of newsprint and printing paper is decreasing and the consumption of containerboards or cartonboards are increasing. An old paper machine can be updated with a grade conversion rebuild to produce more profitable products. Turn a new page for your paper machine with the help from Valmet.

Discover moreServices and automation solutions for forming sections

Explore our latest board and paper press releases

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China

- Sep 26, 2024Metsä Board Simpele improves working conditions and safety with Valmet Fold-up Wall

- Sep 5, 2024Valmet to start change negotiations in Finland in its Paper business line’s Board and Paper Mills business unit

- Aug 16, 2024Valmet and Spinnova Plc sign a partnership agreement regarding process equipment for textile fibre production

- Aug 1, 2024Valmet closes the agreement to acquire majority shares in FactoryPal, a subsidiary of Körber

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States

- Jul 2, 2024Valmet to supply a high-capacity winder to Wuzhou Special Paper in China

- Jun 26, 2024Valmet to supply both a papermaking line and a paper machine rebuild to a customer in Asia-Pacific

- Jun 25, 2024Valmet to deliver a tissue machine to Andhra Paper in India