Forming fabrics for board and paper machines

To improve drainage in board and paper making

Valmet's forming fabrics comprise a wide range of excellent forming fabrics to fulfill all customer expectations. Valmet has constantly improved their forming fabric technology and created fabrics providing excellent runnability, high wear resistance, long running time, good paper profiles and good retention. Specialized forming fabric designs for packaging grades continue to improve drainage. Development work is done closely with Valmet's forming section specialists.

Excellent runnability

High wear resistance

Long running time

Good paper profiles

Valmet Forming Fabric OP for packaging grades

Valmet Forming Fabric OP has excellent dewatering and profile characteristics. Specially optimized for liner and fluting machines, this high-performance fabric improves machine efficiency and paper quality as well as provides major cost savings.

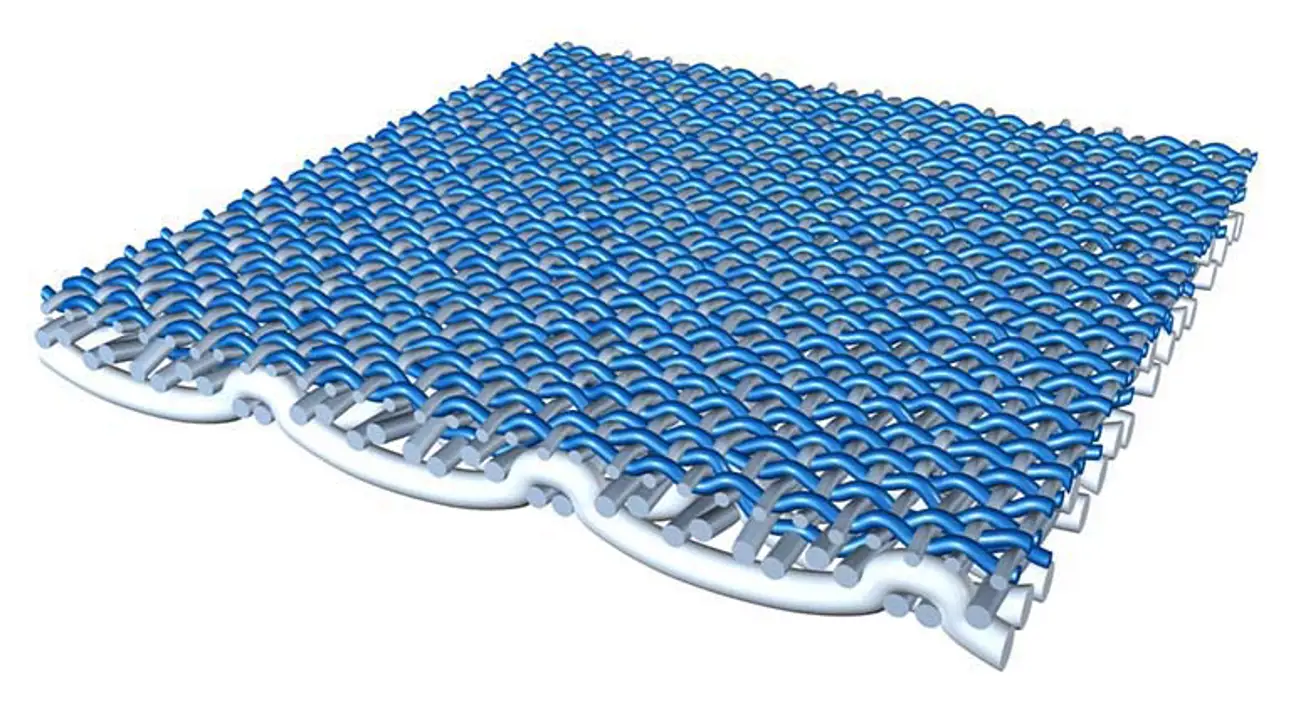

The structure combines a fine paper side and a wear resistant bottom side.

- Cleaner wire loops -> lower break rate

- Long running times

- Lower drive loads -> energy savings

- Higher strength values (CMT, SCT, Burst, Bond)

- Better printability

- More even paper profile

New: Valmet Forming Fabric CSP for packaging grades

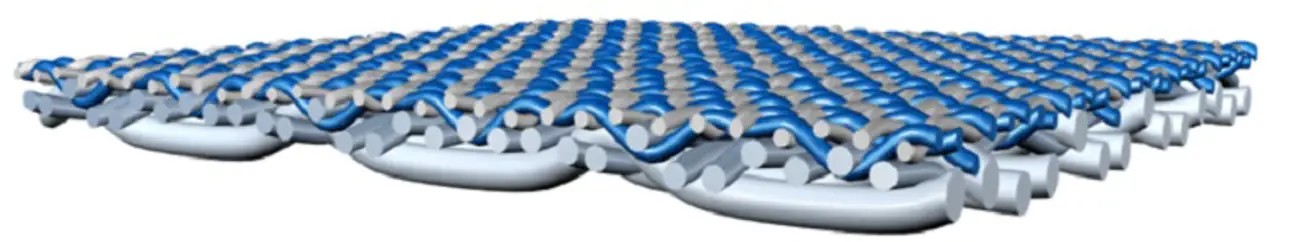

This new generation fabric designed for packaging grade machines improves runnability, in particular, as it runs cleaner. Valmet Forming Fabric CSP has a tighter binding with more binding points. This enables a thin and stable structure with open paper side. On packaging grade machines these fabric properties offer several benefits:

- high drainage capacity and stable dewatering during the whole life,

- less fibre and water carry contributing to cleaner run and improved runnability

- long life

- excellent web properties

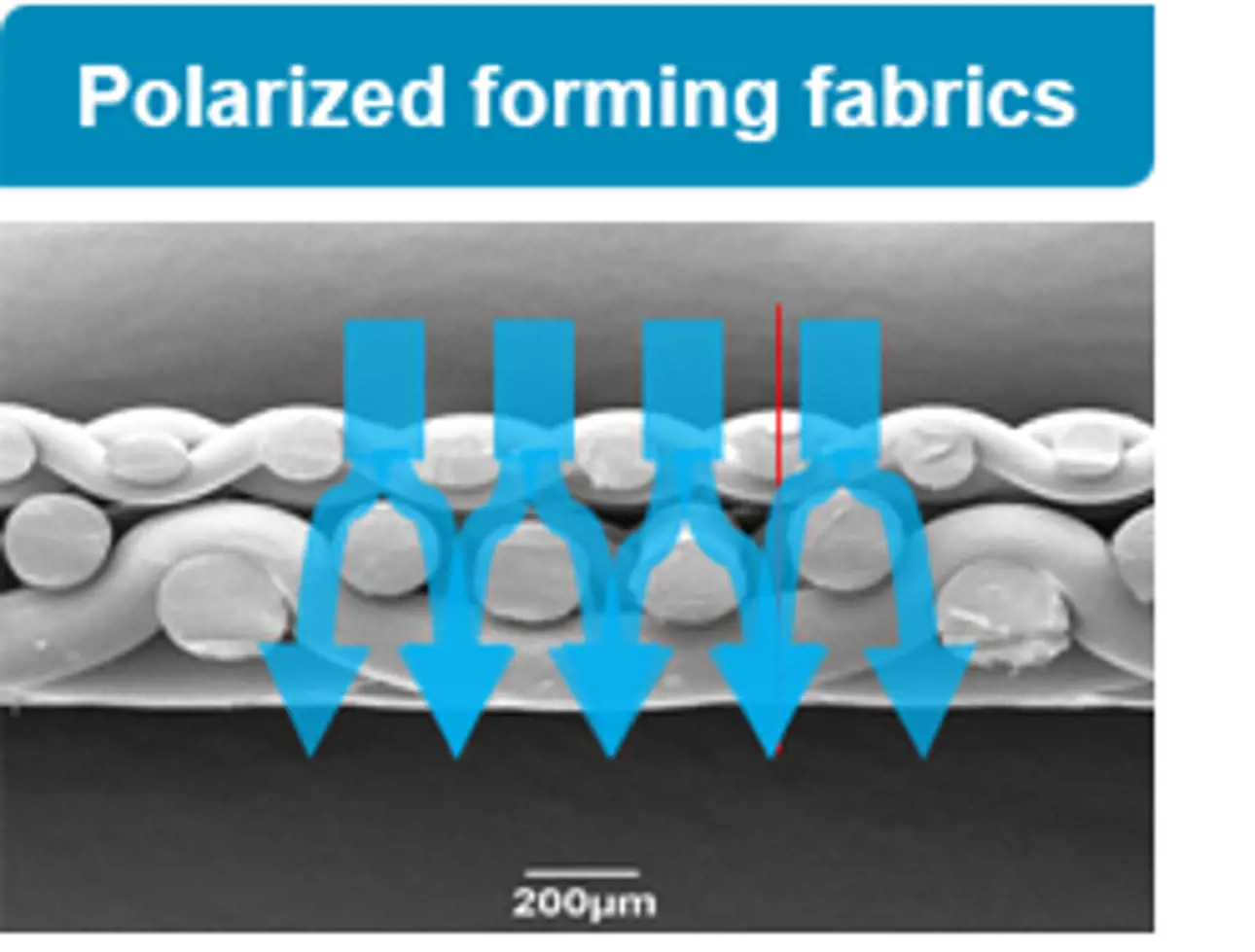

Polarized forming fabrics

Polarized forming fabrics are made with special polarized technology designed to diffuse drainage which results in:

- Very good runnability

- Better cleanliness

- Improved retention

- Excellent wear potential

- Low marking

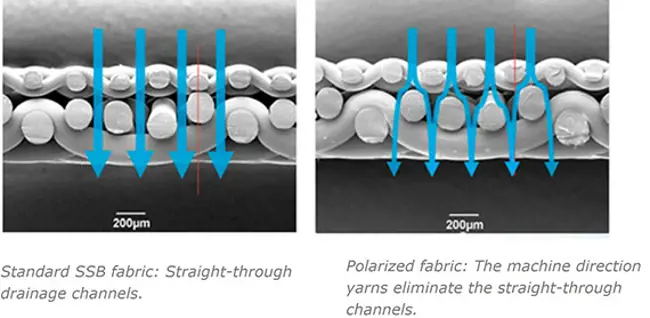

Traditionally, all SSB (sheet support binding) fabrics have had direct drainage channels. In the polarized structure, the machine direction yarns on both the paper side and the roll side are shifted to form an off-stacked structure. This special structure removes the direct drainage channels traditionally used in forming fabrics.

The unique polarized structure allows controlled initial drainage in the paper-making process. That improves retention and helps keeping the machine clean. Good runnability and cleanliness reduce breaks and therefore increase production capacity remarkably. Cost-savings are created by being able to use less chemicals

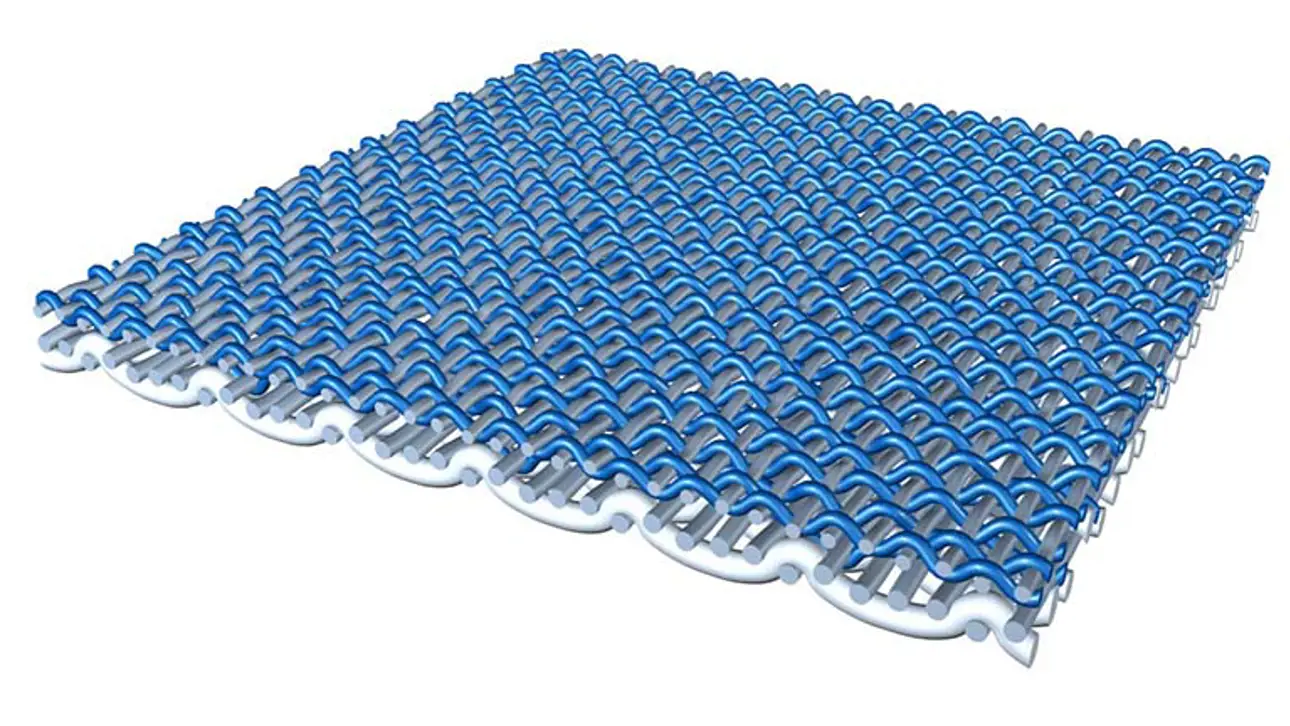

Valmet Forming Fabric GM

Valmet Forming Fabric GM is the widest SSB fabric family on the market and it is designed for:

- Demanding board and paper machine conditions

- Long fabric life

- Even paper profiles

- All printing and writing paper grades

- FBB, liquid and cup boards

Valmet Forming Fabric GM uses polarized forming fabric technology.

In addition to featuring a long lifetime and effective dewatering, the fabrics must have a good retention capability, minimal fiber and water carry, high dimensional and diagonal stability, as well as good fiber support."

Pekka Kortelainen, Product Technology Manager for Forming Fabrics at Valmet

Other Valmet Forming Fabrics:

Valmet Forming Fabric PM:

Durable SSB triple layer fabric for packaging paper and board machines

Valmet Forming Fabric OPA:

Stable SSB fabric with high wear resistance

Valmet Forming Fabric CS:

Thin and stable, providing improved formation, excellent sheet dryness and a clean run

Articles and success cases