Dryer fabrics for board and paper machines

Reliable performance throughout the fabric's lifetime

Valmet’s dryer fabrics are trusted by paper and board manufacturers to speed up drying rate, enhance paper quality and increase energy savings.

Durability

Seam strength

Dimensional stability

Easy cleaning

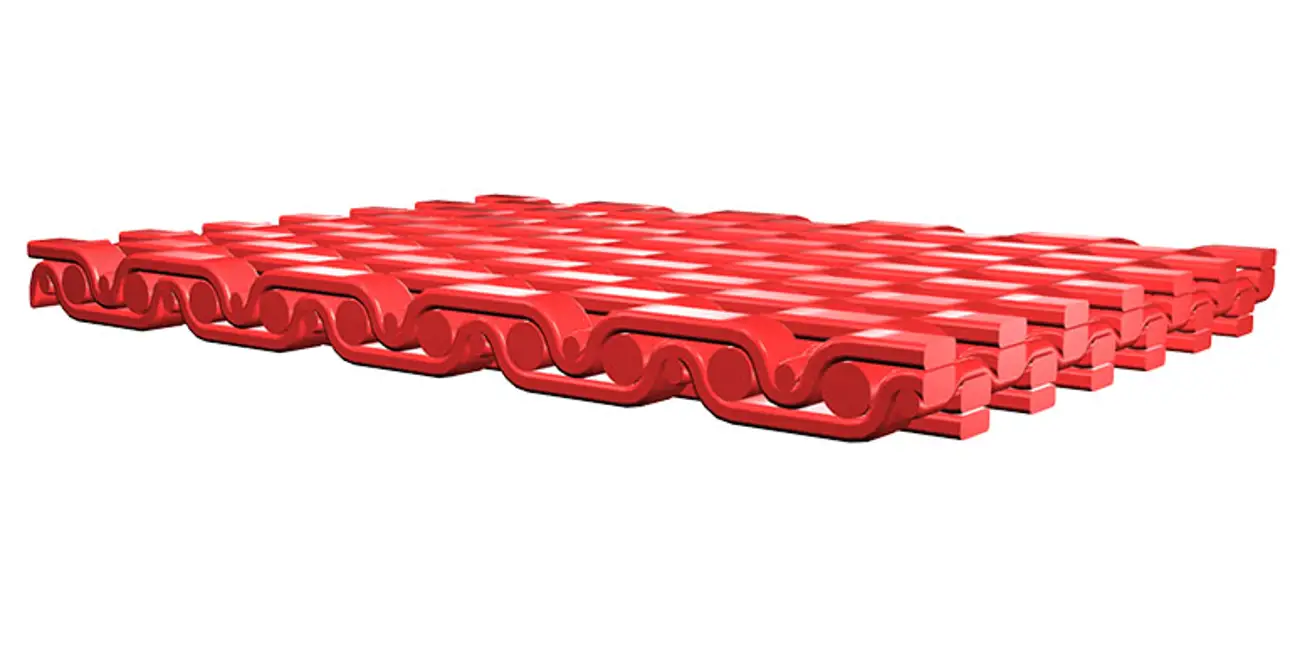

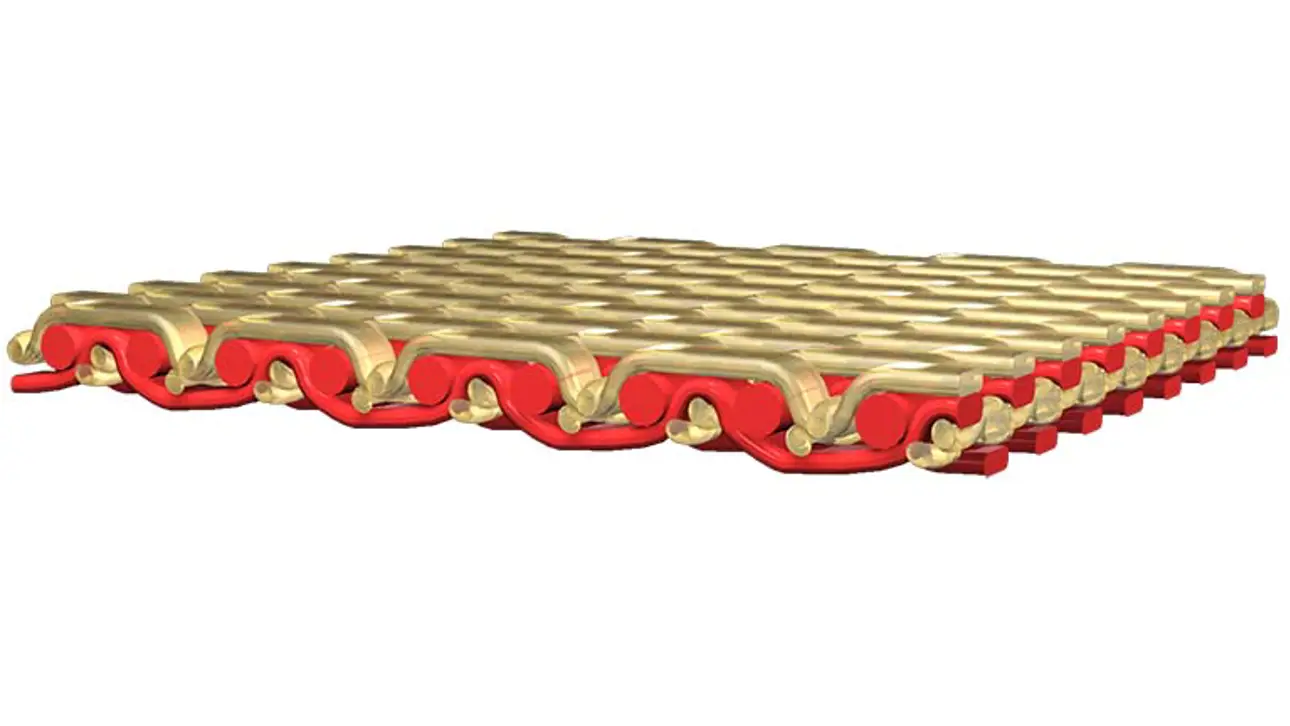

Valmet Dryer Fabric OR

Valmet Dryer Fabric OR is targeted for single felted sections in packaging, printing and writing machines requiring excellent tail threading and runnability. It is a single layer fabric with double warp system featuring:

- High contact surface area and efficient heat transfer

- Excellent wear and jam resistance

- Maximal runnability

- Strong and non-marking warp loop seam

- Flexible and strong edge reinforcement

- Easiness to clean

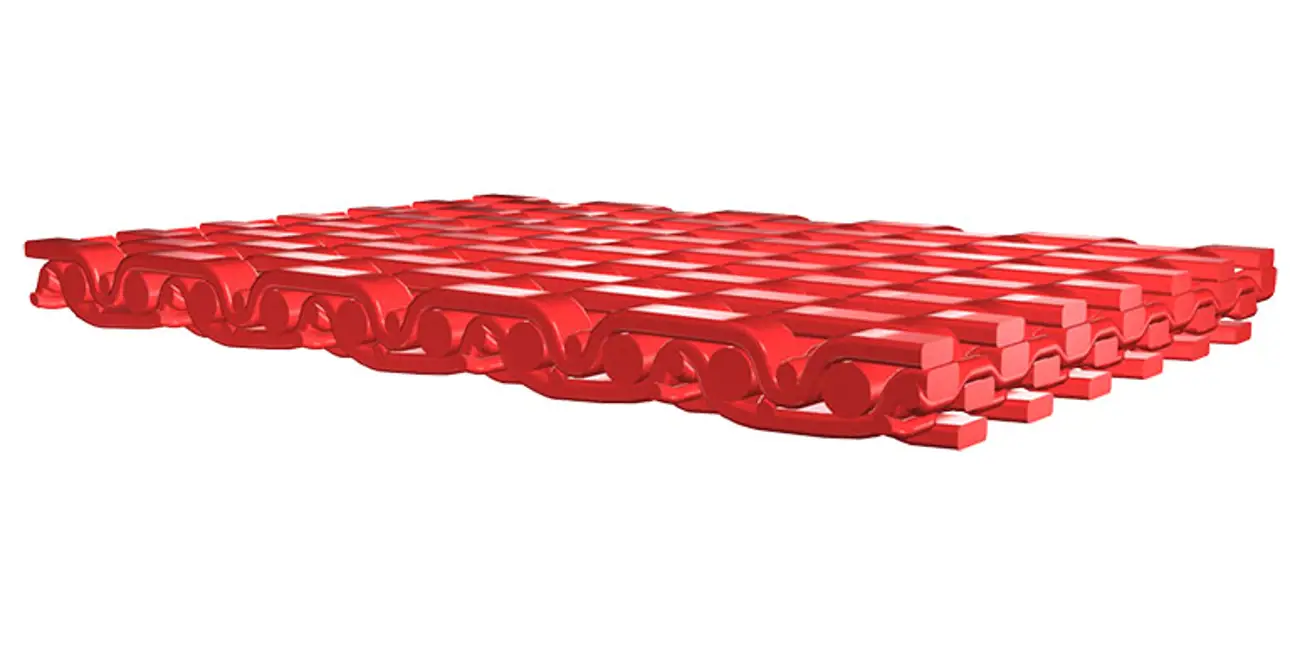

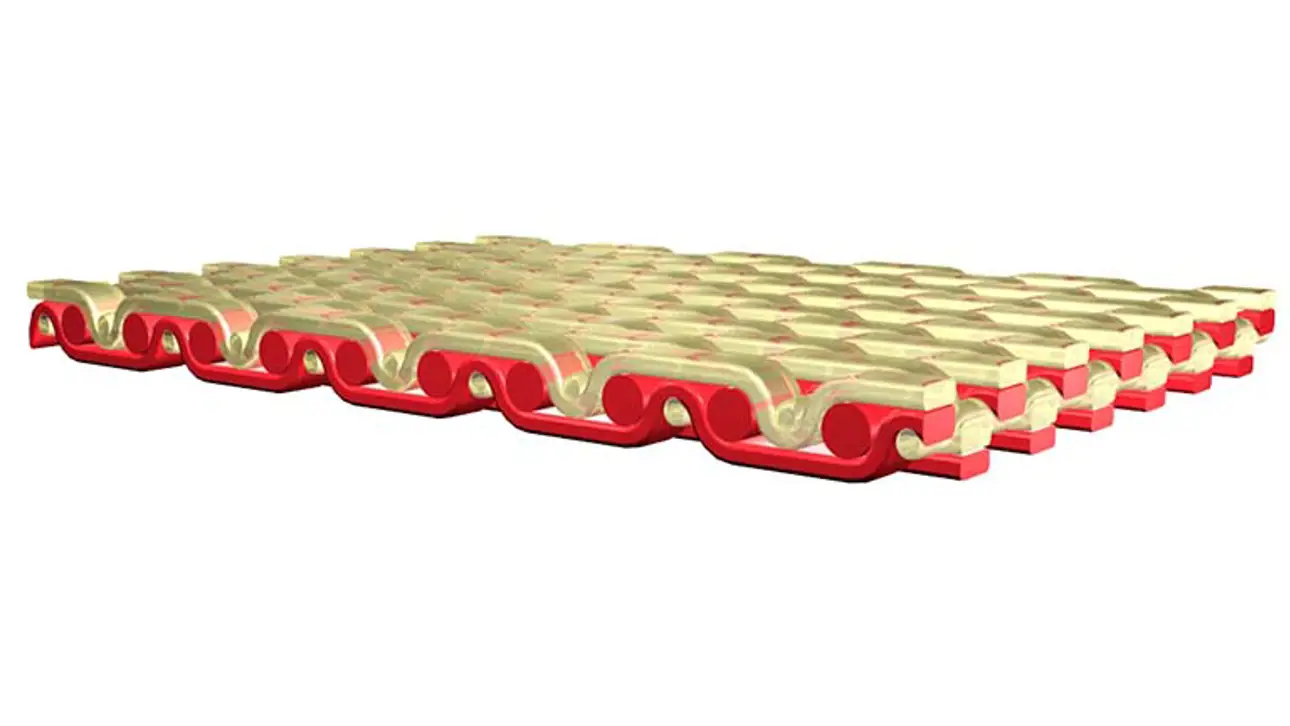

Valmet Dryer Fabric EOS

Valmet Dryer Fabric EOS has a unigue double warp structure. It has excellent accident resistance and is easy to keep clean. Valmet Dryer Fabric EOS has high diagonal stability and therefore low seam distortion, which is beneficial for an even air permeability profile. The fabric features:

- Efficient heat transfer

- Excellent wear and jam resistance

- Improved tailing and runnability

- A strong and non-marking warp loop seam

- Flexible and strong edge reinforcement

- Easy to keep clean

Valmet Dryer Fabric DG

Valmet Dryer Fabric DG is especially developed for packaging grades against contamination. The special fabric surface with low contact area prevents dirt accumulation while maintaining the air permeability of the fabric. The fabric has a double warp structure and features::

- Very good wear resistance

- Excellent strength

- Long running times

- Strong edge reinforcement

- Easy cleanliness

Valmet Dryer Fabric SSO

The SSO fabric is a special fabric for hydrolysis prone positions. It has a double warp structure having flat MD PPS yarns on the paper side and flat MD improved PET yarns. The contact area is high (up to 47 %). In addition it features:

- efficient drying

- a strong warp loop seam

- easiness to join

- excellent hydrolysis resistance.

PPS can resist chemical & thermal attack (MP a. 285 °C) and has extremely good hydrolysis resistance

Valmet Dryer Fabric SSH

SSH is a PPS dryer fabric having a double warp structure. The smooth surfaces on both sides, thanks to the symmetric double warp floats, gives good heat transfer and runnability. In addition it features;

- intensified evaporation

- good hydrolysis resistance

- a very stable and durable structure

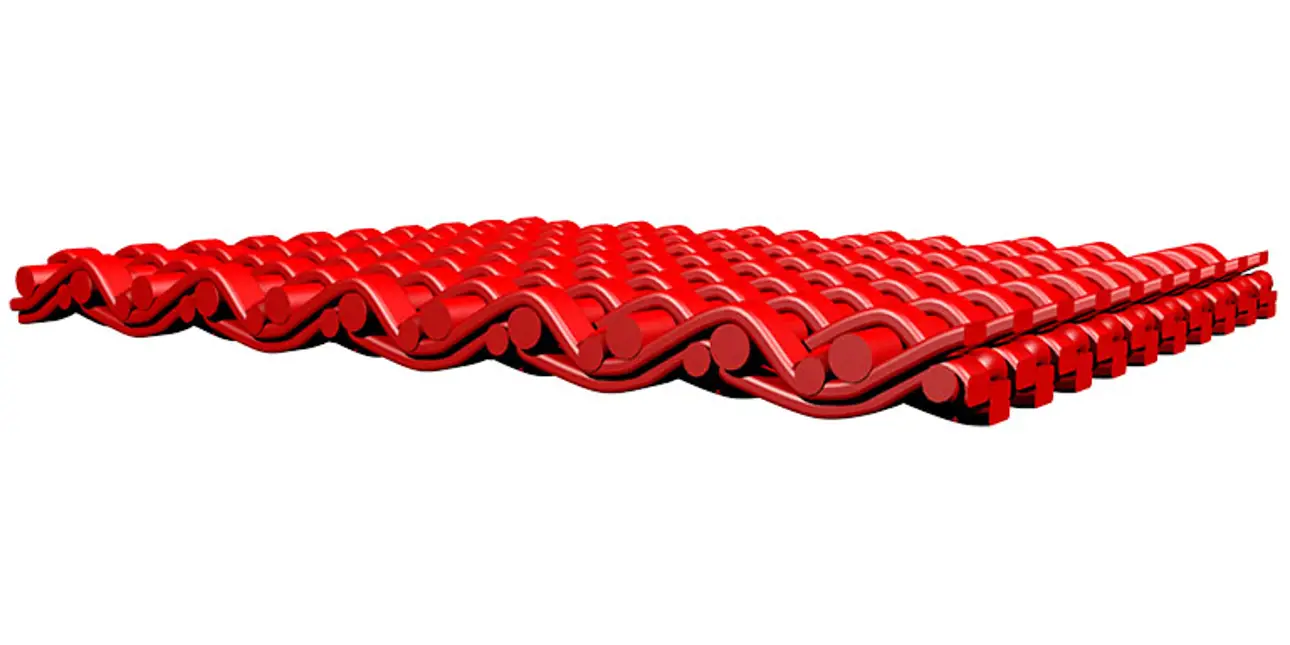

Valmet Dryer Fabric SPF

Valmet Dryer Fabric SPF is a stable spiral fabric with ”dog-bone” filler yarns. The non-twisting dog-bone-shaped filler yarns are more durable against high-pressure showers than traditional filler yarns. The fabric features:

- easy and fast installation (easy to join)

- efficient drying

- high contact area (63%)

- an invisible seam

- no weaker seam area (90 kN/m)

- flat yarns and long spirals

Need support with your dryer fabrics?

Our dryer fabric professionals are here for you. Just send us your question and we'll revert soonest.

Contact us