Minimize CO2 emissions in tissue production

Valmet's target is to enable carbon neutral tissue production by 2030 at the latest. We offer many opportunities to reduce CO2 emissions and other environmental impacts in tissue production through a combination of process technologies, services and automation solutions.

Want to reduce your environmental footprint?

There are many ways a tissue maker could lower the environmental impact. With Valmet's offering of process technology, service and automation we can support you in this journey. We can also inspire you by sharing best practice examples and stories from our customers around the world. Explore opportunities in lowering your energy consumption, minimize water usage and evaluate your fiber mix with the content shared below.

Click on the tissue mill line image below to explore what solutions Valmet can provide for respective section.

Make a change!

Explore how our solutions can contribute to lower fiber, water and energy consumption at your tissue mill.

Contact us todayReduce water in tissue making - invest in the future

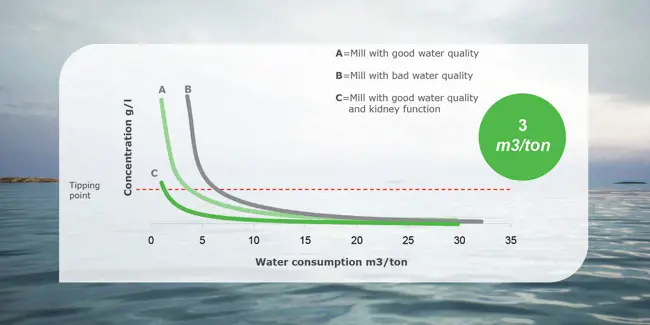

All of us need to implement water saving solutions to have access to freshwater in the future and your contribution makes a difference. Did you know that Valmet can design your tissue mill based on the amount of freshwater you have available?

Talk to us today, together we can make a change for the future!

Explore more about water usage in tissue making

Evaluate your fiber mix - lower carbon footprint and costs

Evaluating what raw material to source, the amount needed and carefully selecting the best process technology solutions can make a big difference, not only related to cost, but also for the environment.

Talk to us today, together we can make a change for the future!

Why lowering your energy consumption?

Energy consumption is the main source of human-induced green house emissions that drive climate change. Together we need to come up with new ways to lower and change the usage. This is beneficial both for the environment and for a company’s profitability.

Total saving potential

Explore the wide selection of solutions that Valmet can present to support your journey to become even more sustainable. We believe that saving potential become greater when combining shared expertise - you as tissue makers and Valmet as a technology advisor.

The calculations to the right provide an example of total saving potential for a full size tissue mill when utilizing the entire offer.

|

Energy |

CO2 |

Water |

|

495 kWh/ton |

96-131 kg/ton |

2,5 m3/ton |

Solutions for reducing your environmental footprint in stock preparation

Explore our process technologies and solutions for reducing energy, CO2, water and fiber.

| Conical Refiner Pro | Delivering performance and efficiency in refining across any application. | |

| Protection screen DX | Best coarse cleaning efficiency at lowest possible energy consumption. | |

| Refiner Fillings | A service solution to improve your refining processes. | |

| Double dilution concept | Increased stock quality with less energy consumption. | |

| White water treatment | For the highest possible filtrate quality. | |

| Vacuum system | Efficient use of the energy and reduced water consumption. | |

| Micro fibrillated cellulose | Microfibrillated cellulose to improve paper properties can make a positive impact on the environment. | |

| Ultrafiltration | Produce colloid-free, bacteria-free and ultrapure water from white water to reduce fresh water consumption. | |

| Fiber Furnish Analyzer | Increased energy efficiency and refiner segment life while maintaining the highest pulp quality. | |

| Consistency measurements | Higher consistency control performance with maximized production and savings in raw materials, chemicals, and energy. |

Reducing emission in the wet end of the tissue making process

Explore our technologies and solutions for the wet-end section of the tissue machine to reduce energy, CO2, water and fiber to minimize your environmental footprint.

| Advantage ReTurne | Recover energy from the headbox. | |

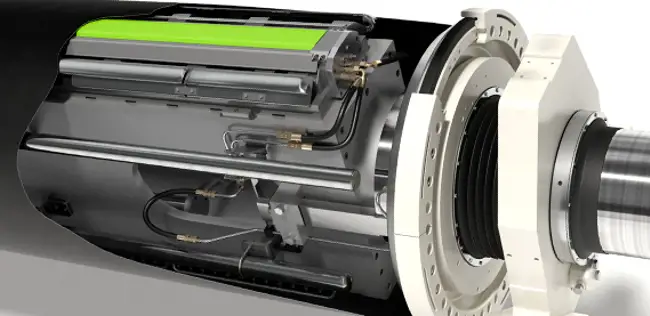

| Advantage ViscoNip Press | Energy savings, uniformity and flexibility. | |

| Advantage ReDry | Re-use the free energy you already have and save energy. | |

| Press Roll Cover PL and PH | Energy savings and improved dewatering with press roll covers. | |

| Suction Roll Upgrade Lock Seal | Suction roll seals for tissue machines for reduced water consumption and energy usage. | |

| Suction Roll Upgrade Shell Flow H | Save water whilst keeping suction roll shell clean. | |

| Nip optimization | Improve nip loading and save energy | |

| IQ Dilution Profiler | Raw material savings due to the possibility to run with lower grammages. |

Solutions for savings in the drying process of the tissue machine

Explore our technologies and solutions for saving energy, CO2, water and fiber in the drying process.

| Drying optimization service solutions | Process and production optimization for tissue making. | |

| Waste heat steam generator | Generate steam re-using the exhaust from the hood. | |

| Burners for alternative fuels | A world of possibilities among hydrogen, natural gas, LPG etc. as well as heating with steam and diathermic oil systems. | |

| Advantage Balance control | A user-freindly and personalized tool to balance your equipment and save energy. | |

| Air to water heat recovery | A smart way to heat up process water. | |

| IQ Quality control system | A Nuclear-free solution to run your tissue making process at an optimum level. | |

| IQ Steam profiler | The highest efficiency steam profiler family to increase production capacity, decrease energy consumption, and improve moisture profile. |

Mill wide technology for reducing emissions

Explore mill wide technologies for lower energy, CO2, water and fiber consumption.

| DNA Automation System |

Operate and optimize the mill efficiently with productivity increasing user interface and built-in controls. |

|

| DNA Information Management |

Real-time monitoring to be aware of the energy consumption and costs helps the operators tune the energy efficiency of the process. |

|

| Biomass boilers | Convert biomass to energy. | |

| ReGen | A sustainable way to use energy cost-efficiently. | |

| Industrial Internet | Industrial Internet applications and services for tissue efficiency. | |

| Electric boilers | External equipment provided upon request. |

Driving long-term development of resource efficient tissue production

Valmet has a long history of leading the tissue industry towards a more sustainable production. Over the years, our professionals world-wide have contributed to innovative products, solutions and processes to lower the energy, water and fiber consumption for our tissue producers. Valmet's own environmental footprint has declined steadily since the beginning of 1990.

80%

less water

47%

less energy

15%

less fiber consumption