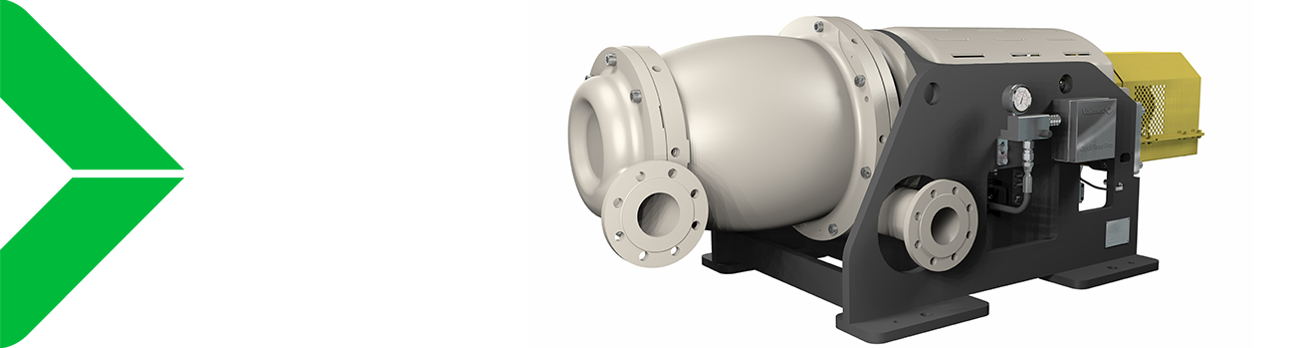

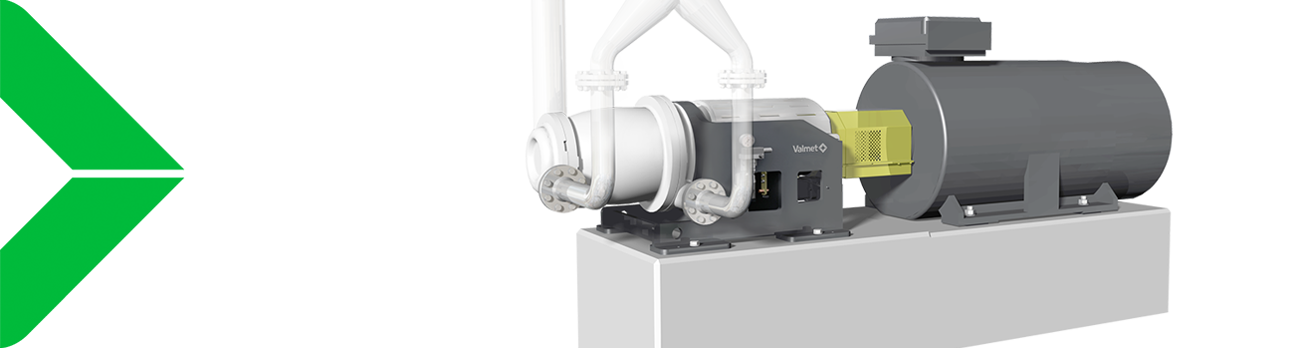

Valmet Conical Refiner Pro

Precise power control

Up to 30% electrical savings

Increased refiner capacity

One Is All You Need

A revolutionary concept in refining, the Valmet Conical Refiner Pro allows two traditional refiners to be replaced with one unit while still delivering a 30% electrical energy savings. The Valmet Conical Refiner Pro refiners are suitable for all kinds of low consistency refining applications.

High Efficiency, Low Cost

Due to allowing for a reduced number of refiners in the system, the Valmet Conical Refiner Pro increases energy efficiency and savings in operation costs all while supporting sustainable development. This ultimately leads to a reduction in maintenance costs, a lower entire life cycle cost, and less environmental stress.

Unique Flow-Through Technology

Stock is spread evenly across the bars where fiber treatment occurs. After treatment is completed, the fiber exits from the refiner. The design ensures that all the stock is treated evenly, providing higher refiner loadability and better energy efficiency.

Exceptional efficiency

The Valmet Conical Refiner Pro enables a higher installed power and throughput while also featuring a lower and more even pumping curve when compared to conventional refiners. Additionally, the refiner’s hydraulic capacity is not sensitive to fillings wear.

A Quick and Precise Power Control

Gap control is made by a moving rotor with a new generation loading system comprising of a servo motor and control.

- A single Valmet Conical Refiner Pro can replace two traditional refiners while delivering a 30% electrical energy savings

- No-load power is reduced by 50%

- Stock is treated evenly, providing higher refiner loadability and better energy efficiency

- A Significantly smaller investment cost

- Suitable for all kinds of low consistency refining applications

We're Here to Help

Looking to see how new technology can impact your process? The Paper Technology Center in Finland can mill scale laboratory trials to using your actual production conditions. Whether it's standard laboratory tests, tear and tensile measurements, or the evaluation of fiber morphology through microscopic analysis, we have the industry experts to help. Read more about our pilot testing facilities here.