Deflaking

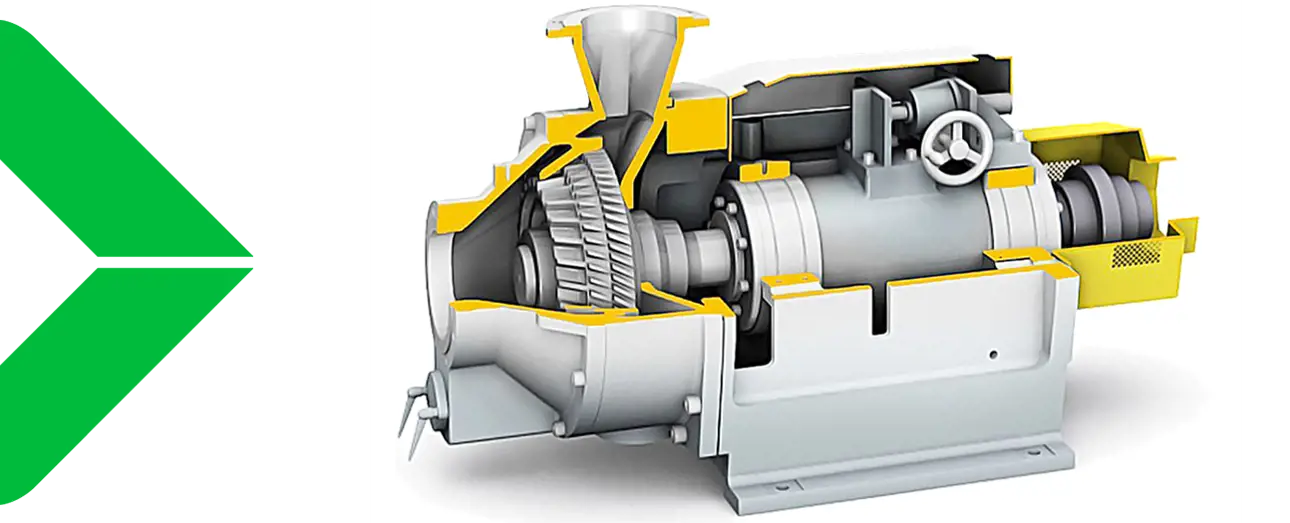

Increase Broke Efficiency With the Valmet Deflaker

The Valmet Deflaker ensures homogeneous stock with excellent deflaking and defibering performance in bale pulping lines, broke lines and for wet-strength grades.

Ensure excellent deflaking and defibering in bale pulping lines, broke lines, and for wet-strength grades with Valmet Deflaking Technology.

What Is Deflaking?

Deflaking offers a tool to eliminate process disturbances in an early process stage. By eliminating large particles from broke, deflaking contributes to a reduced number of web breaks and less screening rejects. Typically, deflaking is applied in CTMP, flash-dried bale pulping, in various coated paper and board machines as well as in tissue broke lines.

Designed to ensure homogeneous stock for further processing through defiberizing of fiber bundles and flakes utilizing pulsation and the friction between the fibers. Proven Valmet Deflakers feature a controllable fillings gap to efficiently break down the fiber bundles and flakes.