Creating additional value streams

In modern pulp production, operating sustainably is a continuous goal – pulp producers around the world are aiming for closed circles and are working to minimize waste and harness side streams. By working closely with our customers and placing heavy emphasis on R&D, we continuously expand our offering with new solutions. These solutions turn different production side streams into new value-adding products such as lignin and sulfuric acid.

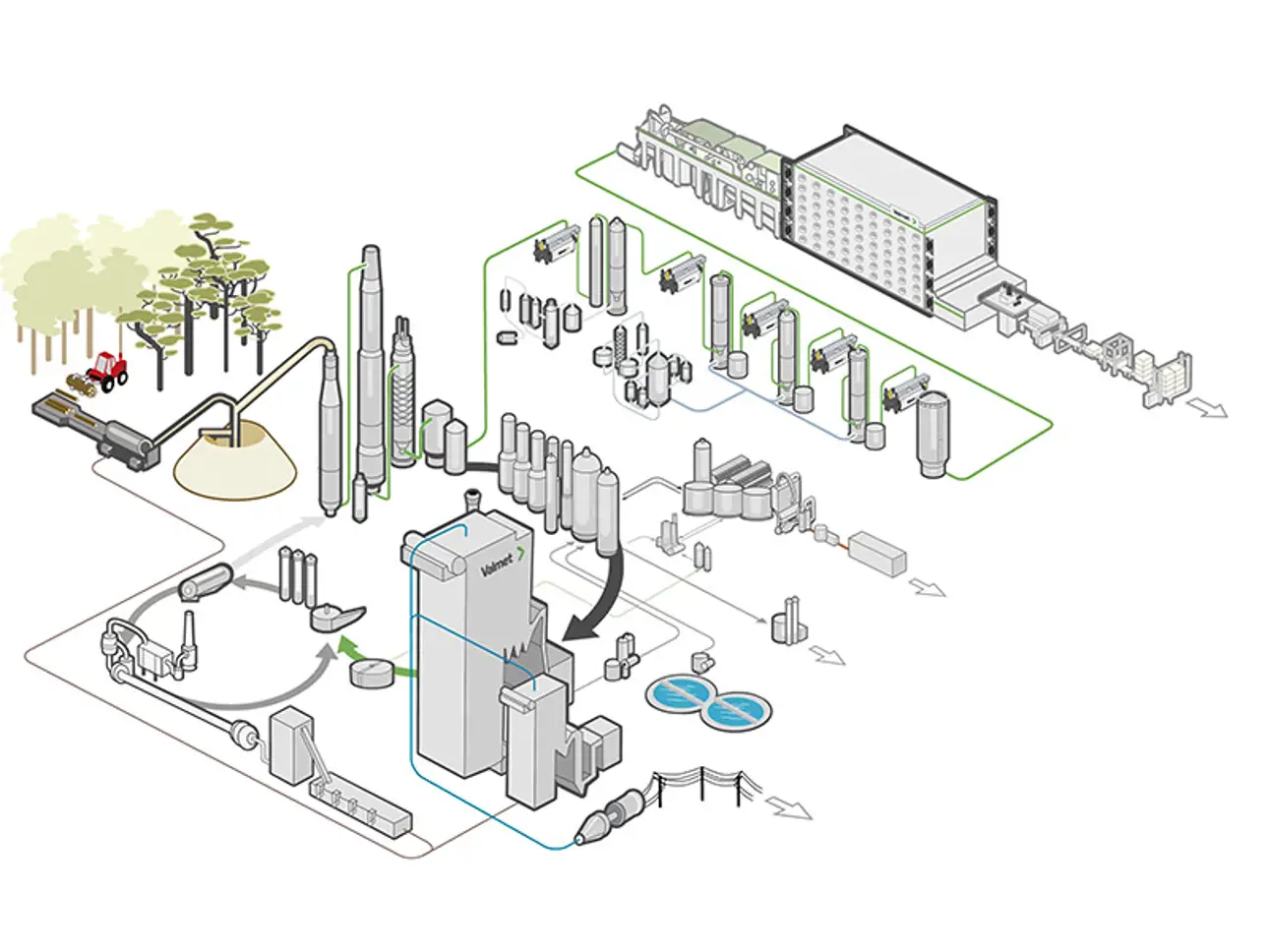

Our solutions