Raising industrial and district heat production efficiency

Valmet DNA Automation for combined heat and power plants

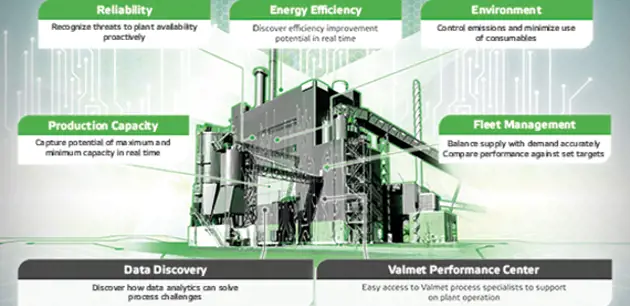

Valmet provides a full scope of products and services for control and monitoring of combined heat and power (CHP) plants. These include plant automation, safety systems, and optimization solutions for steam network and district heating network. Valmet’s expertise improves efficiency of the customer’s district heat production in an environmentally friendly way.

Control and monitoring of the entire CHP plant via a single user interface

Improved energy efficiency for industrial steam production and distribution and for district heating networks

Reduced energy procurement costs and reduced emissions

Further process optimization available with advanced forecasting tools

Maximum process optimization in CHP production

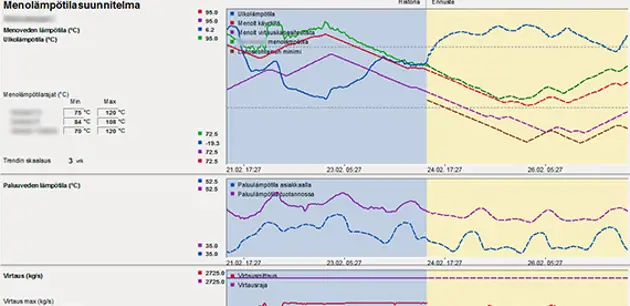

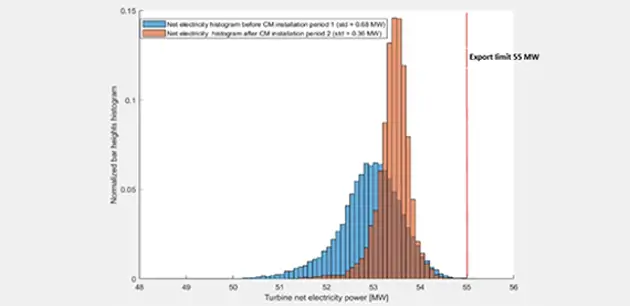

Part of the Valmet DNA Automation solutions, Valmet’s optimization system predicts transmission delays and temperature fluctuations, enhancing energy efficiency of the entire district heating network. In turn, a more optimized operating model reduces energy procurement costs and, consequently, emissions.

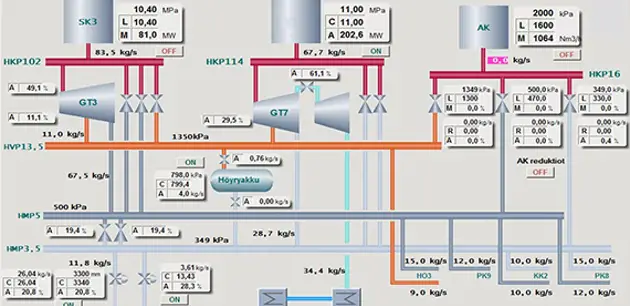

Optimization system also supervises and regulates the whole steam network of industrial plant, ensuring that steam consumption and production are always in balance – in all production situations. It supports plant operators in process risk control and management in the most cost-efficient way and improves the plant’s overall production efficiency. Process optimization is one of the tools used to achieve maximum carbon neutrality in energy production.

Valmet can also deliver tools for load and price forecasting and electricity trading as part of the solution.

High-quality results with decades of power plant automation expertise

Valmet’s references for plant control and monitoring systems include a number of conventional cogeneration plants with various types of boilers and steam turbines as well as combined-cycle cogeneration plants. The offering covers automation solutions for both industrial and district heating plants.

Power plant control system

Monitoring and reporting

Process optimization

Life-cycle solutions and services

Our partners

Would you like to find out more about our automation solutions for CHP plants?

Please let us know more about your needs – and our experts will contact you shortly.

Contact us