Biosludge treatment

Valmet's biosludge treatment system helps keep the secondary water treatment working at its optimum. Valmet's solution results in a positive return on investment compared to traditional ways of handling biosludge.

Biosludge

Biological degradation is an important process in pulp mill effluent treatment. The process includes removal of biosludge, also known as secondary sludge, from the basins. The flow can be in the range of 5-15 kg dry solids per ton of pulp.

Disposal - a challenge

Biosludge is often difficult to dispose of because the heavy odor that is released during decomposition. It is difficult to dewater, which makes landfilling and incineration in a power boiler costly. Incineration can result in loss of thermal efficiency and steam generation, combustion stability problems, corrosion and increased emissions. Landfilling is no longer used in European countries.

Valmet's solution

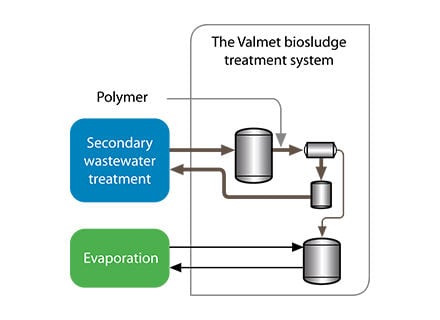

Valmet's solution is effective and efficient. The sludge is treated, mixed into the black liquor and evaporated in the evaporators.

The impact on pulp mill processes is minimal. The process is safe for operators and the environment, it requires very little maintenance and it is easy to control.

Minimized impact

When it comes to emissions of NOx from the recovery boiler, adding biosludge to the black liquor has not had any significant impact on emissions. In some cases, it has been necessary to adjust the recovery boiler air to return the levels to normal, but no rebuilds have been required.

Repeat installations

Valmet has installed the system in a large number of mills. One mill even returned to Valmet to upgrade their installation as the mill had increased the production

Contact us

Valmet's focus is to bring our customer's performance forward. To learn more on biosludge treatment, please contact Kai Lüder at Valmet, phone: +46 31 50 10 00, or use the link below.

Contact us