Doctoring solutions for board and paper making

Optimized doctoring leads to improved machine performance and cost savings

Doctoring affects machine runnability, paper and board quality, production costs, and production efficiency. Runnability can be improved by optimizing doctoring parameters and blade materials. Cleaner rolls result in better end-product quality. The blades can be selected to meet customers shutdown schedule which will lead to fewer blade changes resulting in lower blade costs. The reduction of unplanned shutdowns and costly downtime periods can be avoided by reliable and trouble-free doctoring.

500 tonnes more board production

50% lower doctoring costs

20% lower annual blade costs

0,5% increase in dry content

It's not only the doctor blades - it's the overall approach to improve mills’ doctoring processes

Valmet offers a unique selection of breakthrough doctoring technologies that improve mills’ doctoring processes, both technically and economically. Our customers witness up to EURO 1 million in annual savings, better runnability, efficient dewatering, longer blade lifetimes, and improved safety.

Our complete portfolio includes doctor blades, blade holders, and support accessories that ease and improve the handling, storing, and recycling of doctoring components, and enhance operator safety.

Our expertise ranges from material consultation to professional support and troubleshooting. Depending on process conditions versus blade behavior, we know which materials work best in any given requirement, application, or machine position.

And it isn't just the technology that stands out: We provide life cycle support for mills’ doctoring needs day and night, seven days a week. Our global network ensures that no customer’s mill is left alone with its doctoring process needs.

99% of all doctoring positions can be improved...

Improvements in doctoring come from a variety of sources. It is not only the doctor blades, it is the overall approach. With Valmet’s optimized doctoring solutions paper, board and tissue producers achieve better runnability, efficient dewatering, and energy and doctoring cost savings. Valmet offers a complete portfolio of high-quality doctor blades, holders and accessories with best cost-competitiveness and expert support close to customers to improve the performance of their production process.

High level of performance with Valmet Doctor Blades

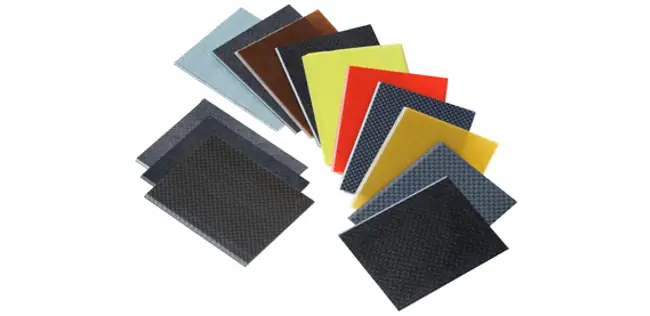

Valmet offers a comprehensive range of doctor blades for all types of machine positions and all process needs in board and paper making. The continuous development and testing of blade materials ensures the reliability and trusted quality of our doctor blades. Reliable sheet shedding and tail threading operations with cleaner rolls result in high-level performance.

Discover our full range of doctor blades

New generation durable, lightweight and corrosion-resistant blade holders

Valmet’s doctor blade holders are designed and manufactured individually for a perfect fit. The durable, lightweight and corrosion-resistant holders eliminate vibration, keep rolls and cylinders clean, and are easy to install and maintain.

View our selection of high-quality doctor blades holdersSupporting accessories for board and paper making

Valmet has a comprehensive portfolio of accessories to ease and improve blade handling, storing and maintenance. All the supporting accessories have been developed to secure operators’ safety and working ergonomics.

Learn more:

- Doctor Blade Cabinet and Trolley

- Doctor Blade Puller

- Doctor Blade Cutter

- Doctor Angle Meter

- Angle Meter – Blue tooth

- Doctor Oscillator

Do you have any questions?

If you wish to get a quotation including technical specifications, prices and expert services, or wish to discuss different solutions concerning doctoring products, fill in the contact form and our experts will contact you shortly.

Contact usValmet's doctoring expertise covers board and paper machine engineering expertise

- Board and paper process and automation expertise

- Extensive expertise in rolls, roll covers and coatings

- An understanding of the variety of factors affecting doctoring, proven by the large number of international patents Valmet holds

- Long-term R&D in doctoring designs and concepts, materials and handling processes

- Reliability from testing with specialized testing equipment

- A truly global network of doctoring professionals on every continent

Learn more about doctoring products from our latest articles and reference stories

Read more about doctoring products

Doctoring is a critical process in the paper industry that involves the use of a doctor blade to remove water, stickies and other impurities from a rotating cylinder, roll or belt. It plays crutial role in tail threading process. Doctoring is used for a variety of applications in paper manufacturing, including cleaning the surface of rolls, removing excess material or coatings.

To ensure effective and efficient doctoring, it's important to use high-quality doctor blades and doctor blade holders. Valmet specializes in providing high-quality doctor blades, doctor blade holders, and related equipment designed specifically for the paper industry. Our products are made from the finest materials and engineered for precision, consistency, and durability, ensuring that your production operations run smoothly and efficiently.

We understand the importance of doctoring and the role that doctor blade holders play in the paper manufacturing process. That's why we're committed to providing the best possible solutions to help our customers achieve optimal efficiency, reliability, and performance. Our team of experts is always available to provide technical assistance, blade maintenance, and training to ensure that your production operations run smoothly and efficiently.

When it comes to doctoring in the paper industry, you can trust us to deliver the best possible solutions. Contact us today to learn more about our products and services and how we can help you achieve your production goals.