Roll maintenance for board and paper machines

Roll maintenance services ensure your machine keep running smoothly

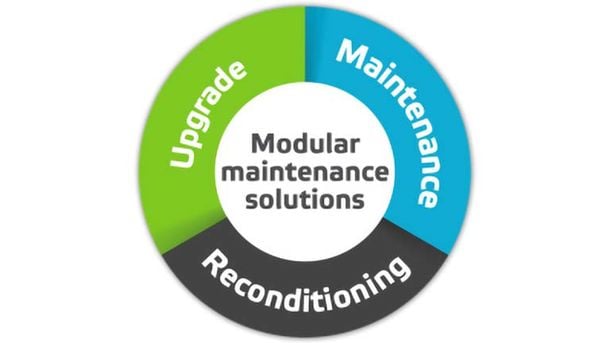

Valmet’s modular maintenance service solutions consists of roll maintenance, roll reconditioning, and roll upgrade services. These solutions help board and papermakers achieve maximum performance with transparent and consistently high-quality maintenance services.

Lower your maintenance costs

Enhance performance and machine runnability

Maximize roll maintenance intervals

Right combination of roll maintenance services for your board and paper machines

No matter what is the set of roll maintenance services you are looking for we can harness it with our modular offering scope. These clear offering modules can be mixed and matched to easily build the service combination you need thus saving both time and money.

Maintenance services available for different roll types:

- Deflection-compensated rolls (shoe, CC and swimming rolls)

- Suction rolls

- Press rolls

- Tube rolls

- Spreader rolls

- Thermo rolls

- Sizer and coater rolls

- Calender rolls

- Reel spools

Clear roll maintenance offering modules

- Maintenance services

The basic scope of the work is to ensure components are in acceptable operational condition, saving on long-term maintenance costs. - Reconditioning services

Thorough inspections of present component condition, an inspection report and proposals for possible additional work and part replacements needed to bring component to “as new” condition. - Upgrade services

Offering upgrades on existing components with modern features, based on customer needs, to enhance performance and productivity.

Your nearest service center can provide proper recommendations on which service module is best for you. In addition Valmet’s on-site roll services provide maintenance services, analyses and audits at the mill site to solve your problems and simply make your life easier.

Benefits of modular maintenance service solutions

- Easy to build the service combination you need from the modules

- Clear offering and scope

- You only pay for the necessary work

- You approve all additional work, including parts and repairs, before it is carried out

Roll maintenance plan for optimal reliability

The basic scope of the maintenance work is to ensure components are in acceptable condition, saving on long-term maintenance costs. Preventive maintenance measures ensure your machine is in operational condition. A scheduled maintenance service plan guarantees the quality level of the end-product and machine runnability for 1-2 years. From receiving to delivery, our specialists can guide you through maintenance processes and selecting spare parts that will be optimal for your board and paper machine.

From timely to condition based-maintenance

The condition-based maintenance services enable planning maintenance actions based on the actual condition of your rolls. Customers can see a significant reduction in maintenance costs as root causes of faults can been identified and maintenance of rolls will be improved leading to extended roll lifetimes and optimized maintenance intervals. Monitoring based on iRoll nip profiles, vibrations and optimization data are some examples where roll condition information is analyzed.

Clear and visual overview to your roll population

Valmet Asset Manageris a web-based computerized system which contains all critical roll-related information in one place. It includes, for example, up-to-date roll status and location information to indicate where each roll is in given time frame, availability of spare rolls and running period statistics. Valmet Asset Manager is easy-to-use tool for mill-wide information sharing.

References and articles

keyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}