Precise roll grinding with 3D roll shape measurement

Precise roll grinding with 3D roll shape measurement Aug 10, 2015 When a worn-out paper or board machine roll is in need of grinding, the first step is thorough measurement. Grinding machines with conventional two-point measuring devices struggle to produce a true roll shape, since geometric imperfections on the rotating roll corrupt the measured surface shape. As a result, grinding machine operators cannot really see what they are getting from grinding.

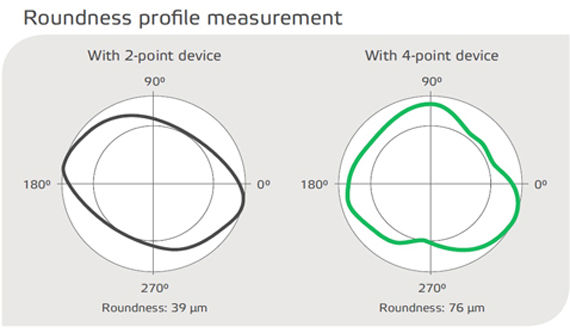

An accurate four-point measurement system is necessary to provide a precise 3D picture of the roll shape. Getting accurate grinding results also needs 3D compensation of the grinding head based on the 3D measurement.

Grinding the roll on its own bearings

In addition to providing a smooth surface, roll grinding permits smooth roll rotation in paper machines. If you grind the roll on its own bearings, the rotation and the shape of the surface is a mirror image of the irregularity of the bearings. While it is normally much faster and easier to grind the roll on its own bearings, it requires a tool to compensate for these irregularities. This tool is proper 3D measurement of the roll in combination with 3D-compensated grinding. The use of 3D grinding results in a perfect roll, meaning that the only uncontrolled element in final use is the precision of the bearings.

Unlike a conventional two-point measuring device (left), a modern four-point (right) measurement system is capable of providing a precise 3D picture of the roll shape.

Extended roll running times and minimized vibration

Advances in roll grinding techniques are providing better roll cover performance for Valmet’s customers. Implementing advanced 3D grinding in combination with state-of-the-art technology brings clear benefits in terms of maintenance work and the end uses of rolls. The quality of roll grinding has a major impact on maximizing roll running times and minimizing vibration.

Using 3D measuring allows roll grinding tolerances to be set and tuned according to the customer’s particular needs. Maximum running time for covers can be achieved without spending unnecessary time on roll grinding.

Tailor-made, cost-effective solutions for all kinds of rolls

Valmet applies the latest 3D grinding technology and expertise all over the world, meaning that grinding quality targets are always met and the result is fit for purpose. By transforming local competence into global expertise, Valmet’s reliable 3D grinding methods means we are able to meet every customer’s individual surface finish requirements.