Roll upgrades for board and paper machines

Upgrade services improve roll performance

Upgrade services provide improved roll performance and productivity by applying new innovations into your existing roll base. Valmet modular maintenance solutions such as upgrade services are especially targeted for critical process rolls e.g. deflection-compensated rolls and suction rolls in board and paper making.

Better machine runnability

Improved machine efficiency

Extended machine time

Reduced energy consumption

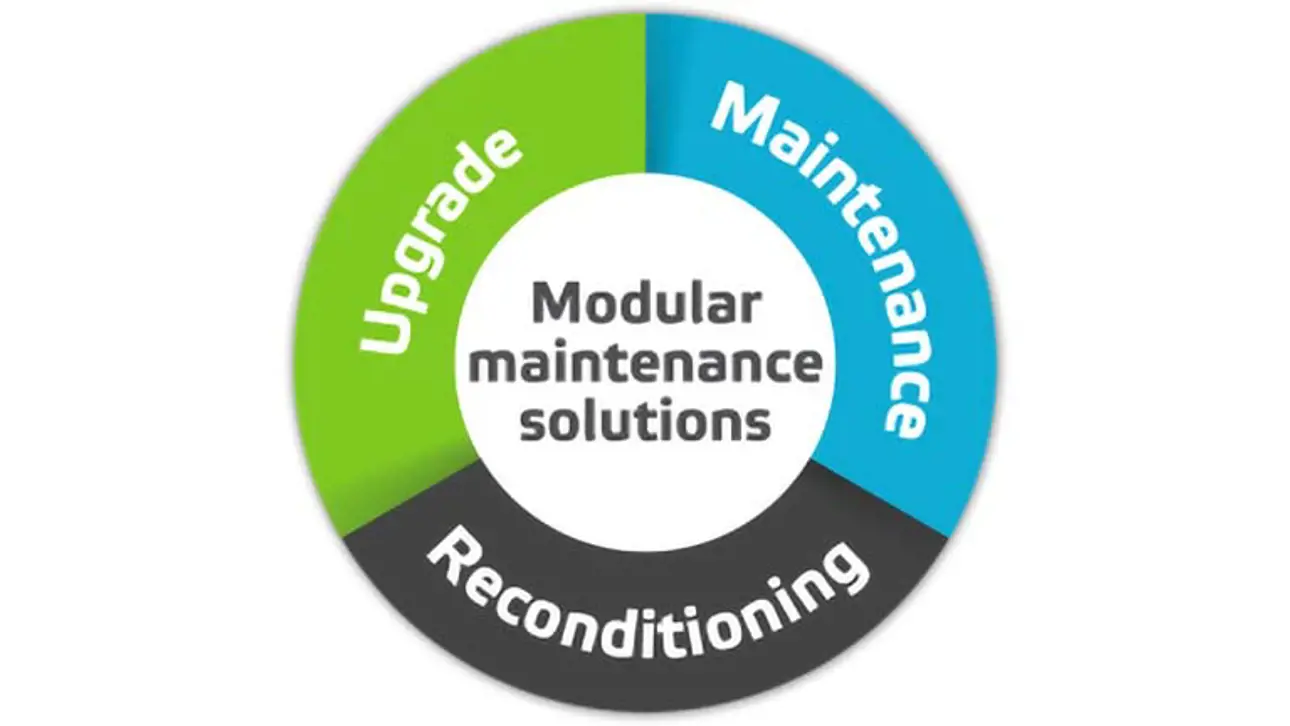

Modular maintenance solutions

Valmet's modular service solutions consist maintenance, reconditioning and upgrade services. Roll upgrades for existing components with modern features enhance performance and productivity in board and paper production.

Your nearest service center can provide proper recommendations on which service module is best for you.

Up to 50% water savings with roll upgrade

One example of upgrades is Suction Roll Upgrade Seal Flow. With Seal Flow, it is possible to achieve savings of up to 50% on the water used in the showers (calculated for 9 meter shell length).

| Comparison | Water consumption l/s/m | Water consumption m3/y | Annual water cost |

| Original | 0.22 | 59,900 | EUR 59,500 |

| Seal Flow | 0.11 | 29,250 | EUR 29,950 |

| Potential annual savings: | EUR 30,000 |

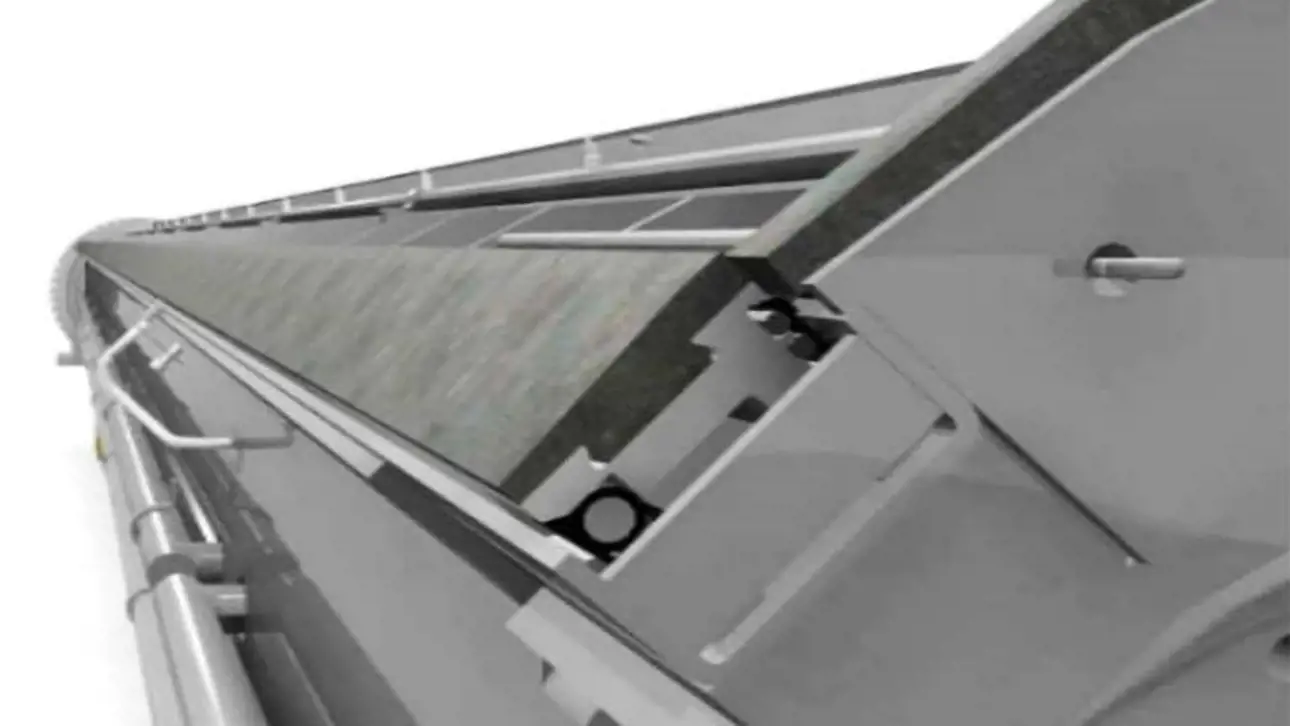

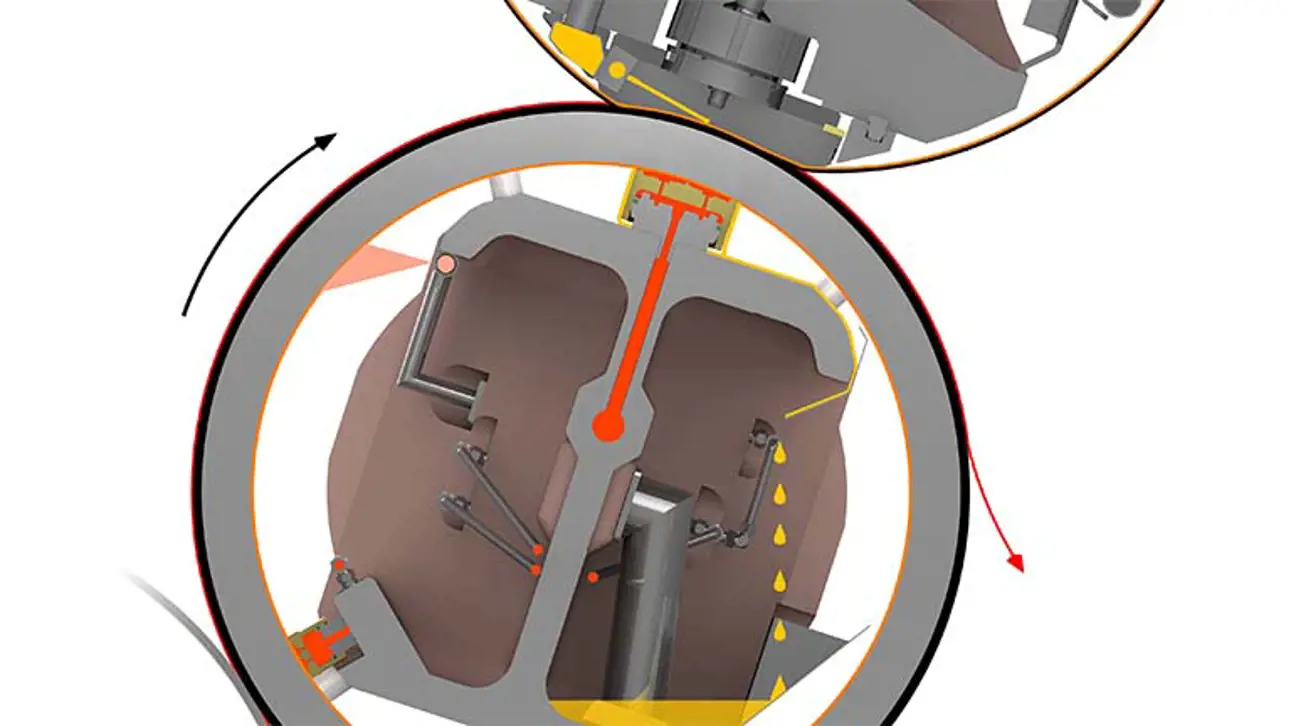

Suction roll upgrades

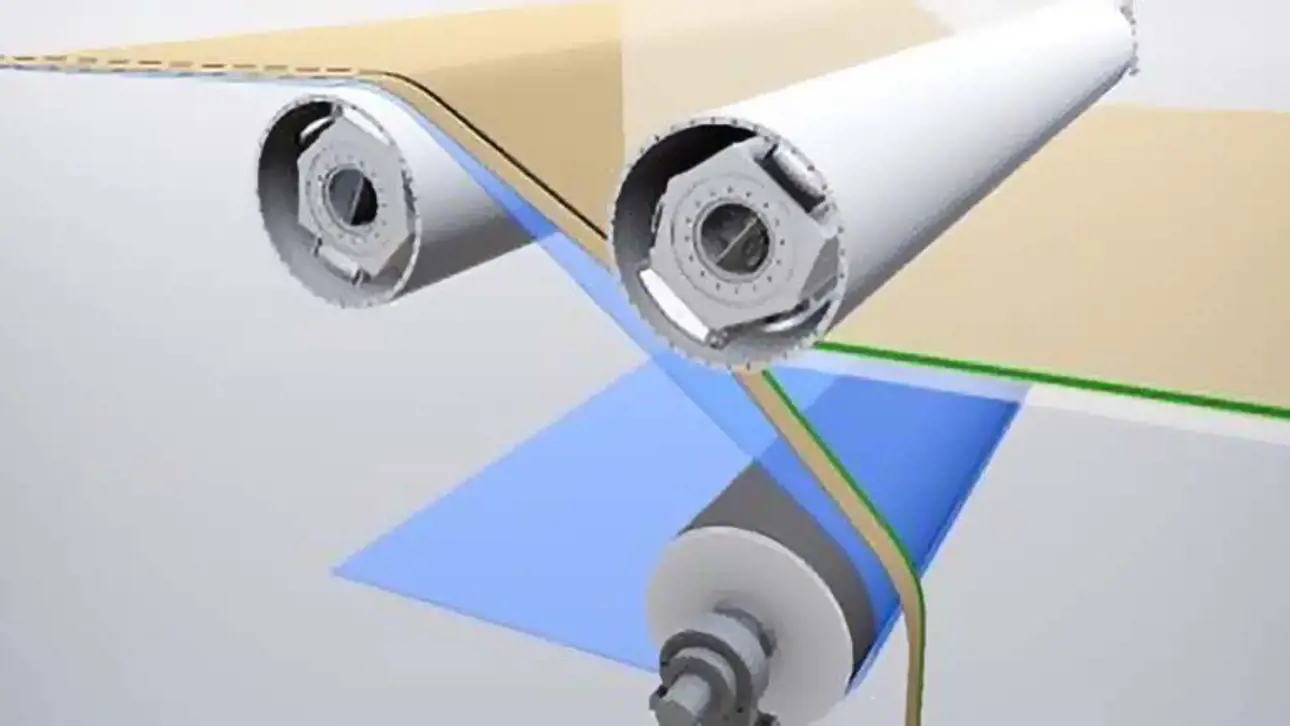

Valmet Suction Roll Upgrade Seal Flow

- Uniform axial seal lubrication

- Minimized re-wetting

- Up to 50% less water consumption

- Up to 30.000 m3 annual water savings

- Extended axial seal life

+1000 deliveries

Valmet Suction Roll Upgrade Lock Seal

- Reduced power consumption

- Longer axial seal lifetime

- Longer shell lifetime

- Lower axial seal noise

- Improved moisture profile and less rewetting

- Up to 10% decreased power consumption

- CO2 savings 0,14 kg/ton

+900 deliveries

Valmet Suction Roll Upgrade Shell

Flow H

- Cleaner shell through holes

- Maximum dewatering capacity

- Improved CD moisture profiles

- Up to 85% less water consumption

- Up to 6.000 m3 annual water savings when using for 10 min time period every 8 h

+100 deliveries

Valmet Suction Roll Upgrade Edge Blow

- Less web breaks

- Improved machine efficiency

- Cleaner shell edge areas

- Cleaner felt edges

- More accurate vacuum width adjustment

- 0,2% more production (+1223 ton/a.)

- Up to 250 t CO2 savings/year due broke reduction

+200 deliveries

Valmet Suction Roll Upgrade Edge Light

- Easy vacuum zone (CD & MD) adjustment

- Improved runnability

- Improved energy efficiency

- Maximized dewatering

+25 deliveries

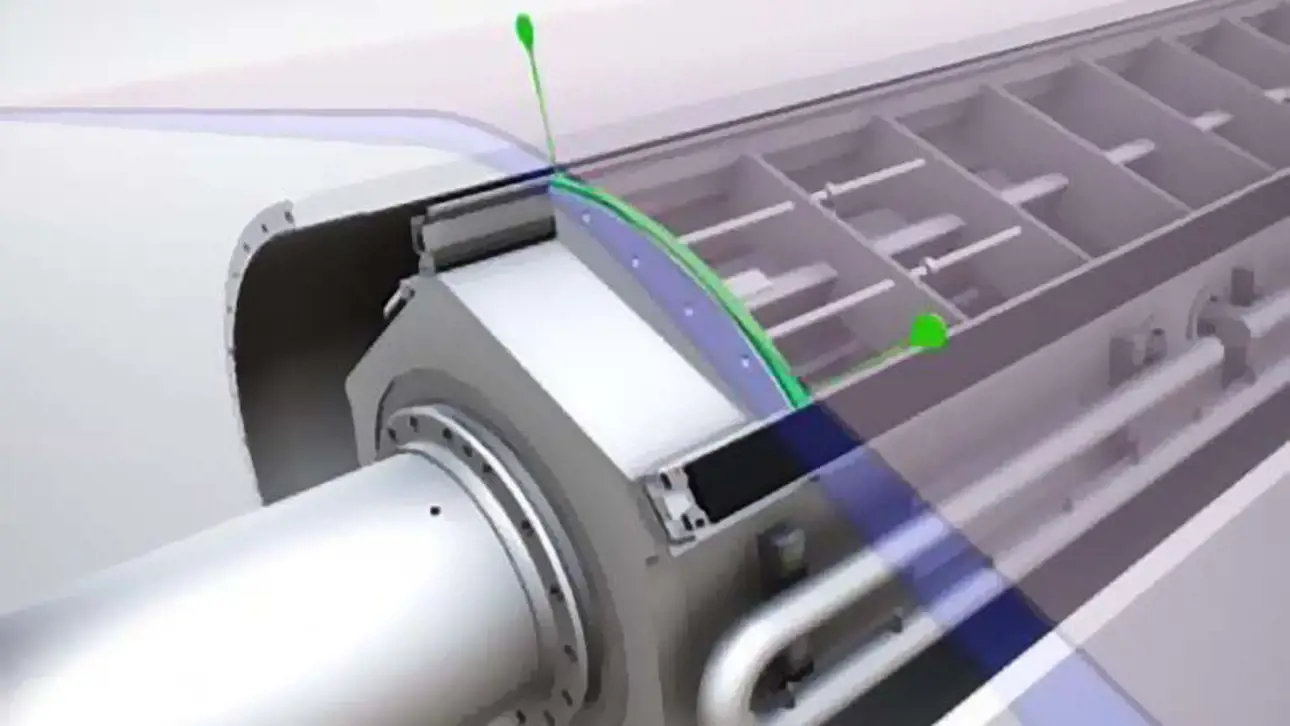

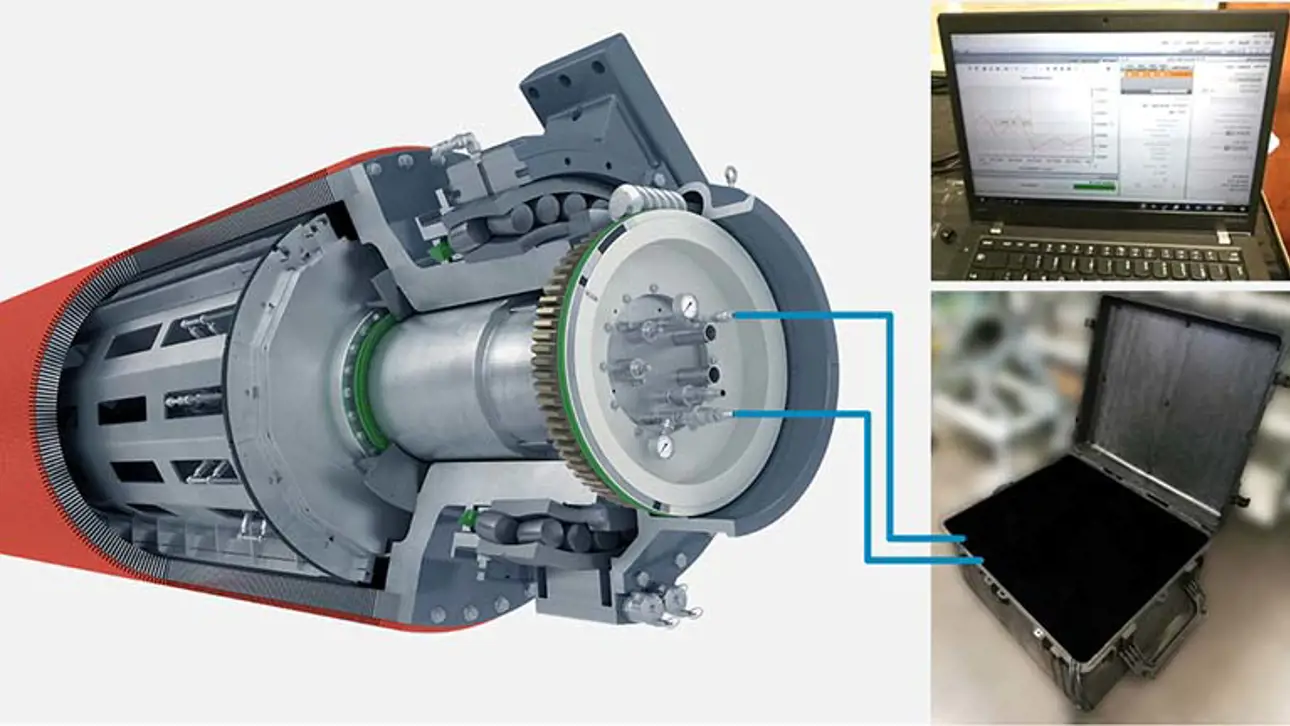

Valmet offline axial seal wear and leakage test

- Measurement of axial seal loading hose air volumes which correlates axial seal wear amount

- Increased run cycle based on actual seal wear

- Ideally timed replacement of suction roll axial seal

- Leakage of loading hoses can be detected

- Prevented unplanned maintenance

- No high investment needed for new axial seal system

+ 10 roll measurements

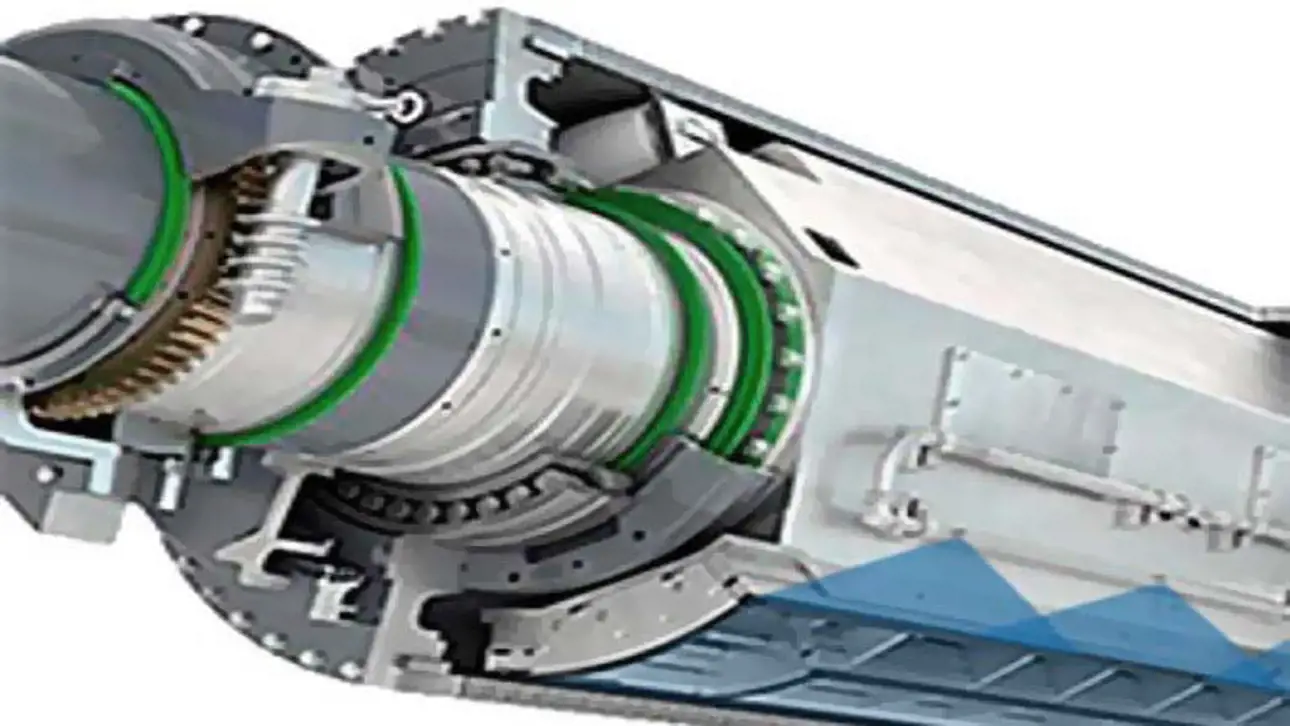

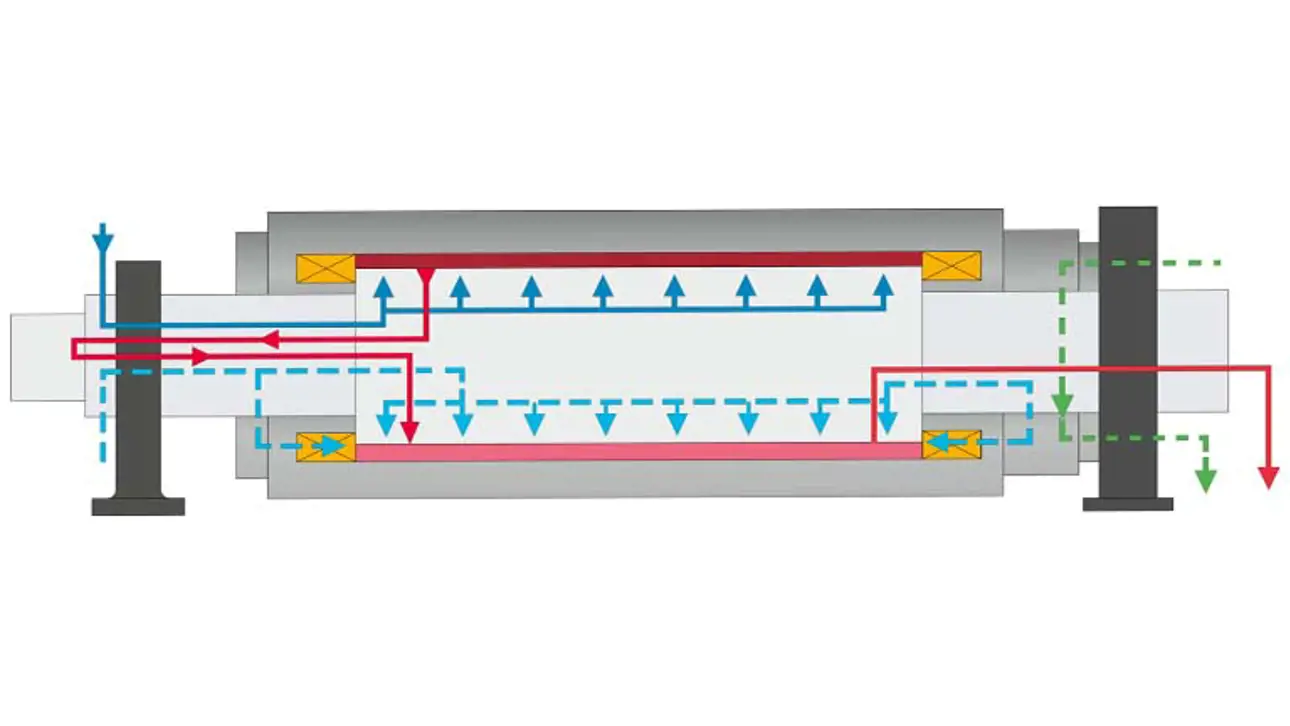

Deflection-compensated roll upgrades

Oil viscosity upgrade for energy savings

- Energy savings up to 14%

- Improved oil condition

- Optimized roll internal cooling capacity to secure long cover lifetime

- Unnecessary roll internal cooling shower and umping capacity removed

- Up to 14% less power consumption

- CO2 savings 1,2 kg/ton

+10 deliveries

Cooling and lubrication upgrade

- Optimize roll internal cooling capacity to secure long cover lifetime

- Remove unnecessary roll internal cooling shower and pumping capacity

+10 deliveries

Double oil circulation

- Additional cooling capacity allows increased machine speed

- Uniform temperature and nip profiles

+80 deliveries

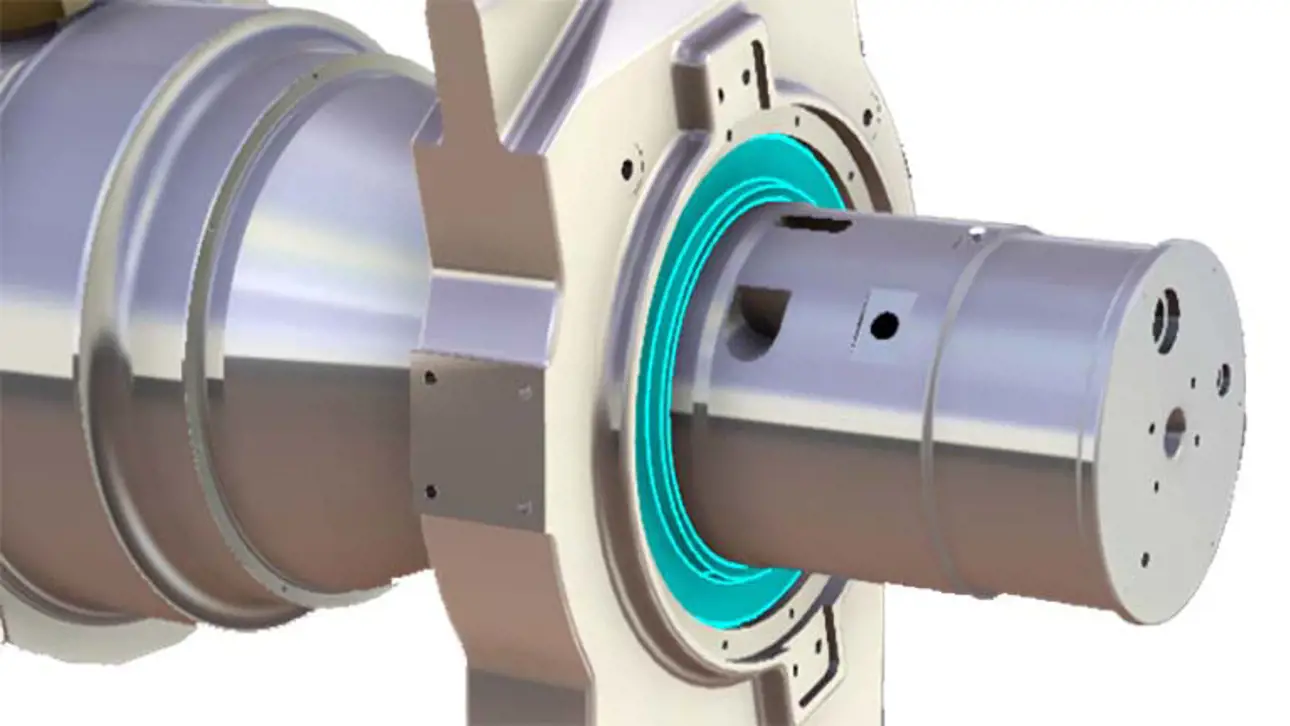

Plain bearing lubrication upgrade

- Prevents corrosion and the bearing from seizing to the center shaft or the pedestal

- Improved lubrication due to grooved plain bearings

- Longer lifetime for bearings

- Guarantees easier and cheaper maintenance

Plain bearing lubrication +10 deliveries

References and articles

Related pages