Smurfit Kappa successfully uses Valmet Bale Tester

Jan 25, 2024

At Smurfit Kappa Belgrade mill, the Valmet Bale Tester has enabled optimized production process and improved the paper quality. Valmet Bale Tester is a reliable and real-time measuring system for analyzing the quality of recovered paper.

Smurfit Kappa is the global leader in paper-based packaging with over 350 production sites around the world. In Belgrade, the capital of Serbia, Smurfit Kappa operates the country's oldest paper mill and produces over 120,000 tonnes of recycled containerboard annually.

To continuously improve its operations, Smurfit Kappa invested in Valmet Bale Testers for several of its mills, one of them being the Belgrade mill. The mill’s Production Engineering Manager, Tomislav Juričić, considers the Valmet Bale Tester an effective solution to better control the quality of the recycled raw material used at the mill.

“The raw material we use in the production, OCC which is recycled packaging paper, is very specific, and there are many challenges related to its quality. The key driver for the investment was the need to better analyse the quality of the raw material delivered and increase the automation level of the quality control process,” Juričić says.

Valmet Bale Tester enables automated quality control

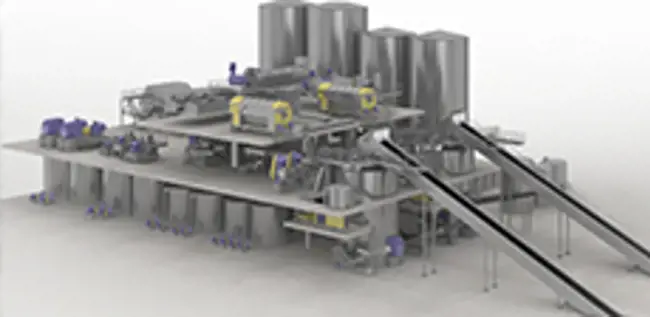

Valmet Bale Tester is an automated quality control system for recycled raw material. The device measures the moisture and other contaminants such as plastic and ash of the raw material in real time. The information is automatically stored in the customer´s database and accessible by the mill´s ERP system where the data can be easily analyzed and further utilized in the production phase.

“All in all, Valmet’s solution offers faster measurement of the raw material delivered at the mill. The automated process, measurements’ accuracy and the random selection of samples guarantee an equal treatment of all suppliers. Knowing the composition of the bales also makes it possible to optimize the production process accordingly, resulting in better product quality,” Juričić says.

“In addition, it has enabled us to develop a bonus system for our suppliers – the better the quality of the recovered paper delivered, the higher the compensation for it, and vice versa” he adds.

Good communication leads to successful installation

The installation of Valmet Bale Tester at Smurfit Kappa Belgrade was completed as planned despite a few unexpected challenges caused by a carrier strike and a broken component.

“The communication with Valmet’s team was excellent and the work was very well organized on both sides, enabling quick adjustment of plans when necessary. I appreciate Valmet’s professionalism and availability during the project as well as their commitment to the mutually agreed safety standards. We have felt fully supported during and after the installation of the device,” Tomislav Juričić concludes.

Tomislav Juričić, the mill´s Production Engineering Manager, considers the Valmet Bale Tester an effective solution to better control the quality of the recycled raw material used at the mill.

Contact us

If you want to learn more about Valmet Bale Tester, contact our Project Manager Iraide Larrea.

ContactRead more about Valmet Bale Tester