Related

Efficient flotation with maximum aeration rate

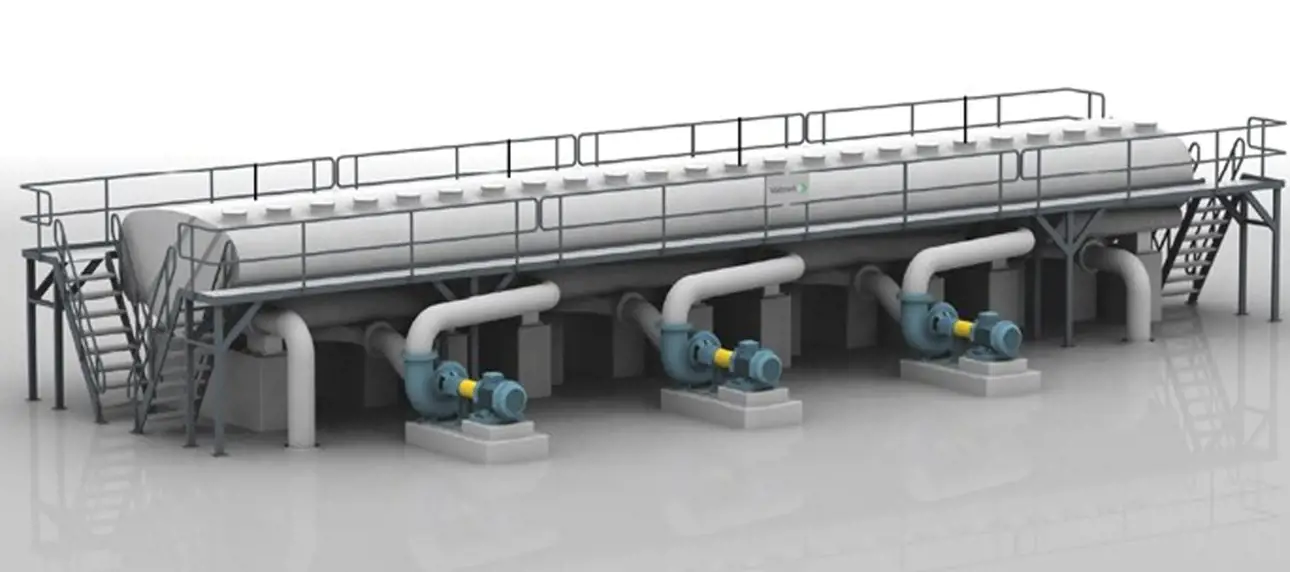

Optimize ink removal with Valmet OptiDeink Flotation

Paper, board and tissue makers rely on Valmet Flotation technology to remove ink, ash and microstickies from pulp.

A successful flotation process removes high levels of ink while minimizing secondary stage fiber losses and overall chemical consumption. Valmet’s OptiDeink Flotation technology delivers a stable solution that helps mills achieve their flotation goals with 20% better aeration and easier maintenance than conventional technology.

Key features

- Compact design to help mills save space/footprint

- Layouts available for both primary and secondary stages in both pre-and-post flotation

- Unique cell design with common control levels for optimized flows

- Optimized injector jet nozzles (providing increased jet surface area and maximum air

- aspiration flow) for better ink removal

- Efficient drainage of froth

- Easy access to air chambers and jet nozzles provide easy maintenance