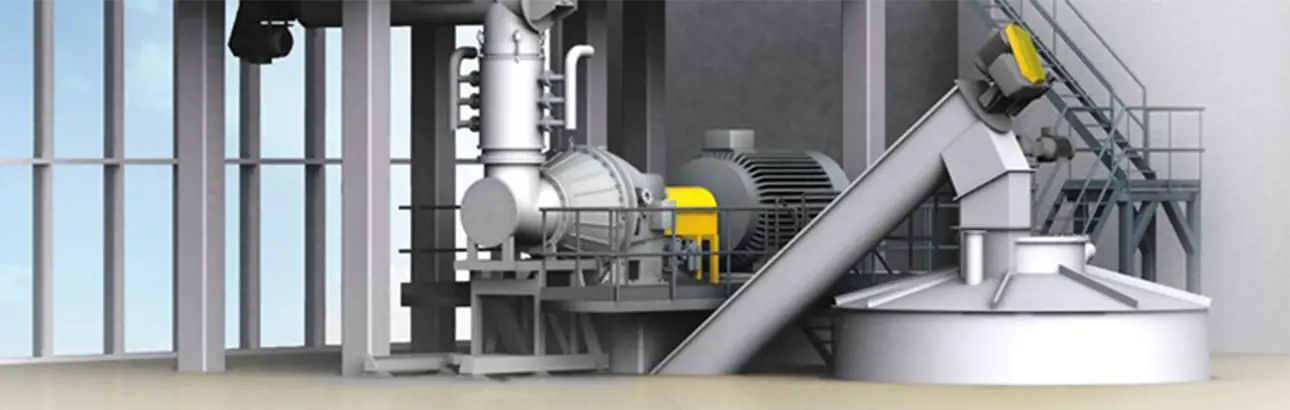

Dispersion and refining

Optimal dispersion technology improves pulp quality by reducing the particle size of undesirable contaminants affecting the downstream processes in recovered fiber systems. In demanding OCC processes, dispersion also improves fiber strength and machine runnability. Accurate refining provides smooth board machine running and determines quality and final product properties. Valmet’s OptiFiner family includes both conventional conical and double-disc refiners, securing stable operation and a uniform refining result.