Automated paper testing anywhere

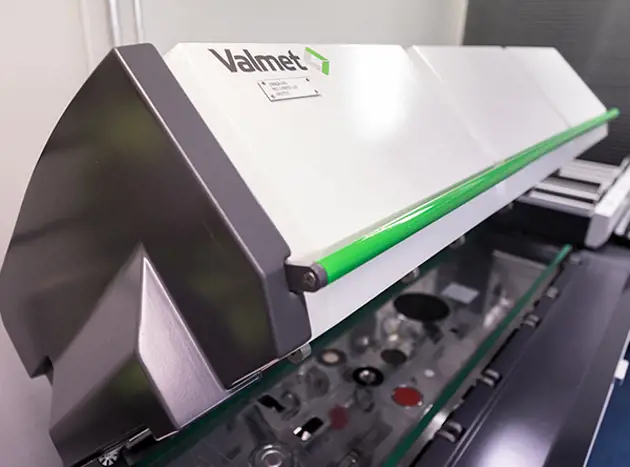

Valmet Paper Lab

The Valmet Paper Lab is an automated, mobile board and paper quality testing laboratory that streamlines your end product quality management. It gives you freedom – in the lab and right out next to the line – to get instant results where you need them for faster decision making.

Move lab testing next to the line for real-time communication and faster results

Ensure compliance with all paper industry testing standards and norms

Boost productivity through safe, easy and consistent testing

Meet the testing demands of modern makers

Long gone are the days when manual paper quality testing in a laboratory serves the needs of paper and board makers. The Valmet Paper Lab allows you to react faster – or even be proactive – to off-spec or unexpected situations.

You can use the Valmet Paper Lab to test all grades of paper and board. Compact and easy to operate, the Valmet Paper Lab frees up the lab and simplifies testing on the production floor. Speed up laboratory work or get results right off the production line.

With the Paper Lab, you can conduct industry-standard tests just minutes in the laboratory – or immediately at-line – after every reel turnup. Individual rolls can be checked before they leave the winder or sheeter to allow for proactive quality management decisions.

Reliable results with solid payback

With hundreds of units in use worldwide, the Valmet Paper Lab has a proven track record of streamlining end product quality testing for paper and board makers. In addition to machine operation optimization, the reliable and rapid measurement results can be used as a quality stamp for the end product.

Automated testing enables more frequent, accurate and repeatable test results. You can quickly make adjustments and get back to running paper production on-spec. This also helps achieve optimal raw material and energy utilization with minimized environmental impact.

The Paper Lab lets you reach your target quality grades faster. Quickly customize end products to exact customer specifications so that you focus on production performance sooner. Move beyond traditional lab limitations and find new cost-saving opportunities.

Standardized testing made easy

All Valmet Paper Lab testing modules comply with standards established by ISO and the paper industry’s major technical associations. You can rely on the results from Valmet Paper Lab measurements when evaluating your paper quality.

The dynamic and informative user interface and sample feeding system provide a much-appreciated user experience. The low noise level of Valmet Paper Lab makes the analyzer suitable for continuous use in a laboratory environment. An automatic frame opener and a shutting procedure using two separate buttons helps sure operation remains as safe as it is simple.

Operators can trust in the convenience and functionality that are cornerstones of the Valmet Paper Lab. A fully automatic, heavy duty testing system for board and paper applications with a wide range of measurement modules. Each module arrives fully factory certified and ready to perform. Accurate testing can begin in a matter of hours.

Expand testing as needed

A key feature of the Valmet Paper Lab is its modularity to better respond to your current testing needs. With tests for over 400 properties, the measurement platform comes in different sizes to provide a perfect tailor-made fit to your needs. You can begin with a few modules and grow over time.

Paper Lab components you may already have can be fully utilized as part of your evolving system. All modules work together as a seamless package, ensuring the highest level of productivity at lowest cost of ownership.

The Valmet Paper Lab is constructed of heavy-duty elements for top performance right next to the paper machines. To extend the product life cycle and lower the cost of ownership, Valmet uses Asset Predictive Performance tools in developing all product and maintenance programs.

Valmet Paper Lab Multimedia Tool

In our Valmet Paper Lab Multimedia tool, you can find thorough information about board and paper automated quality testing as well as animations and information about each measurement module.

Access the toolAvailable measurement modules

- Burst

- Tear

- Tensile Strength

- Smoothness Bendtsen top & bottom

- Smoothness Parker Print Surf (PPS) top & bottom

- Smoothness Sheffield top & bottom

- Smoothness Bekk top & bottom

- Smoothness Porosity-Oken top & bottom

- Porosity Bendtsen

- Porosity Gurley

- Porosity Sheffield

- UV-Color Diffuse

- Gloss Tappi 75° top & bottom

- Caliper

- Basis Weight

- Tensile Stiffness Orientation

- Multi-Filler

- Moisture

- Short-Span Compression (SCT)

- S-Test

- Bending Stiffness (Board and Paper models)

- Blackening

- Scarredness

- Formation

Downloads |

||

|---|---|---|

| Valmet Paper Lab Brochure | View all material | |