Total and true ash consistency for a stable wet end

Valmet Retention Measurement

The Valmet Retention Measurement (Valmet RM5) wet end sensor can be used in any application needing continuous, single line measurement of consistencies. It is the only solution on the market capable of measuring total, ash, fines consistencies, and furnish flocculation accurately.

Stabilizing consistencies - Real-time total and true ash measurements help keep processes running smoothly

Improve machine cleanliness - Reduce raw material costs, fiber material loss, and lower water usage

Accurate chemical dosages - Ensure you only use what you need and realize practical savings

Cleaner wet end for better productivity

Able to measure real total and true ash consistency, the Valmet Retention Measurement (Valmet RM5) sensor forms a solid base for advanced, integrated process monitoring and control. Improve runnability with fewer breaks and higher productivity. Make quicker grade changes and startups while running higher machine speeds.

A stable wet end also helps ensure uniform quality with better system cleanliness and fewer washings. Versatile and reliable measurements are why Valmet Retention Measurement has been the industry standard for decades.

Providing real-time, continuous monitoring of wet end consistency and retention, the RM5 is suitable for all pulp types in applications such as:

- Automated closed loop wire retention control solutions

- Paper and board machines of all types and sizes

- Headbox and white water

- RCF and DIP applications

- Tissue machines

Improve process monitoring

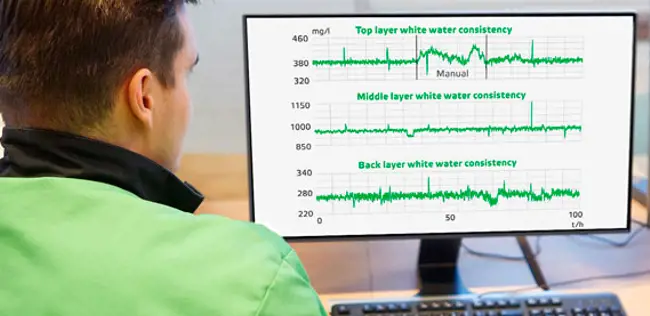

With a versatile, reliable and continuous window into wet end conditions, you can quickly see the changes happening in the process. The Valmet RM5 supports decision making and helps identify and localize problems so you can quickly find the right solutions.

Use the analyzer for online response to, for example, chemical test runs. Not only are the test runs faster, but you also get to process optimization faster with less laboratory work.

Better control over closed loops

The Valmet RM5 is the only sensor in the market for automatic closed-loop wire retention controls. Continuous online information from state-of-the-art optical measuring ensures reliability and accuracy in all situations. You can improve wet end stability, minimize needed resources (fresh water, steam, chemicals, fiber material losses, etc.) and gain higher efficiency.

The Valmet RM5 can be used to adjust filler flow to keep headbox ash consistency stable during breaks. Recover faster from breaks with less production losses by quickly reaching your paper ash target after the break. This is especially valuable with board and paper grades when final product ash is controlled with Valmet IQ quality control system (QCS).

In addition, consistency control can be used to automatically adjusts retention aid flow to keep white water consistency stable. This enables more uniform paper quality with less variation in white water and headbox consistency. The Valmet Stand-Alone Retention Control (Valmet RET) has been developed for this application, integrating the Valmet RM5 measurement and with retention control.

|

Benefits |

Measurements |

|

|

Production profitability by controlling your stock preparation and wet end process

Stock preparation and wet end processes are typically full of unknowns for board and paper makers. But controlling these process areas will enable optimization to gain energy & chemical savings, uniform quality, and better machine runnability.

Check out more info on this below.

Downloads |

||

|---|---|---|

| Valmet Retention Measurement Brochure | Valmet Retention Measurement Datasheet | View all materials |

Related solutions