OptiWin Pro two-drum proactive winder

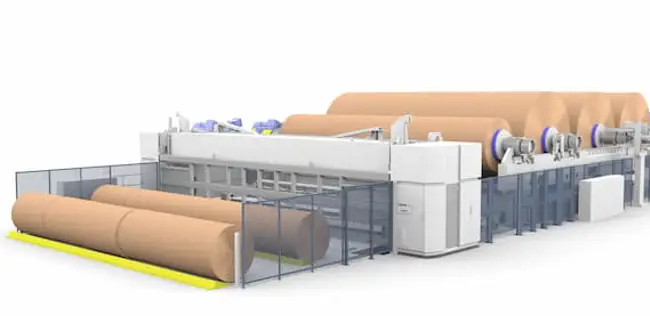

High productivity and capacity winding with just one winder

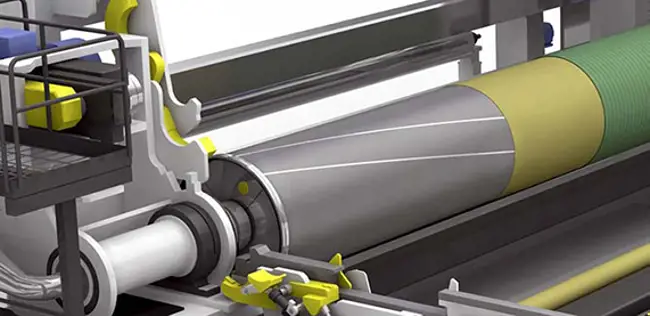

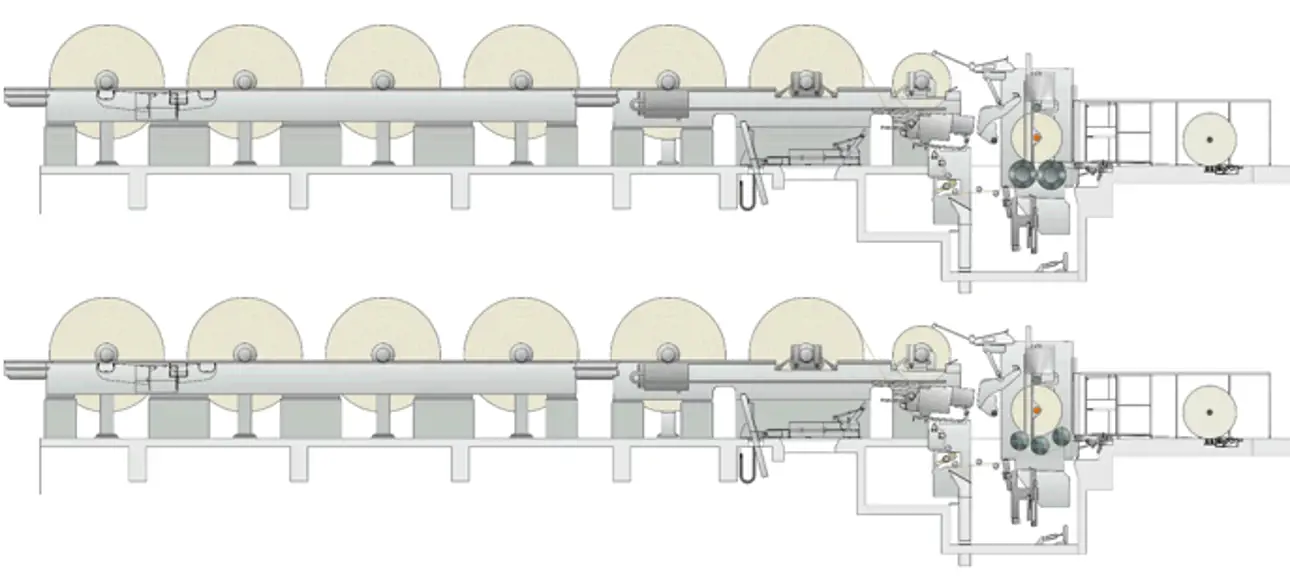

OptiWin Pro two-drum proactive winders feature same the two-drum or belt-bed winding methods than OptiWin Drum or OptiWin Belt winders. Compared to OptiWin Drum or OptiWin Belt, OptiWin Pro has even higher capacity due to its proactive winding geometry, faster sequences, and many advanced winding tools.

Extremely high capacity

Low operator costs

No broke

OptiWin Pro equals two winders

OptiWin Pro winder can be equipped with dual unwind with splicer, the fastest parent roll change system in the world.

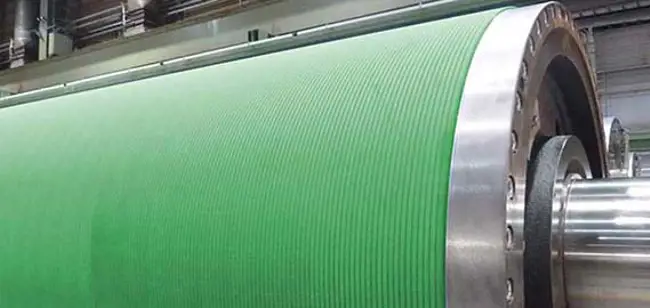

OptiWin Pro is the first comprehensive approach to eliminating vibration on winders. This is achieved by improving the resistance to vibration in all crucial winder components, such as the core locks, rider roll beam and drums. As a result with proactive geometry, OptiWin Pro makes it possible to equip vibration-prone and fast production lines with just one winder.

OptiWin Pro highlights

- High capacity based on a 15-second set change and good runnability due to excellent vibration control

- Adjustable gap between winding drums to avoid running in resonances

- Low operator costs due to high level of automation

- No broke due to excellent spreading, automated sequences and vibration control

We invite you to carry out your winding trials at Paper Technology Center. All winding technologies can be tried out with your own paper or board.

Want to talk to our winders and roll handling experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsInterested in pilot trials?

We offer the opportunity to experiment and develop paper and board products and processes without having to put your own production on hold. This is very cost-efficient compared to expensive tests in your own production. Follow the activities in the trials on site or remotely through live streaming cameras.

Contact our pilot trial expertsHow to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookPlanning a grade conversion?

The world is changing fast; the consumption of papers is decreasing and boards increasing. Update your paper machine with Valmet to produce more profitable products.

Discover moreLearn more about the services and automation solutions for winders

Explore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy