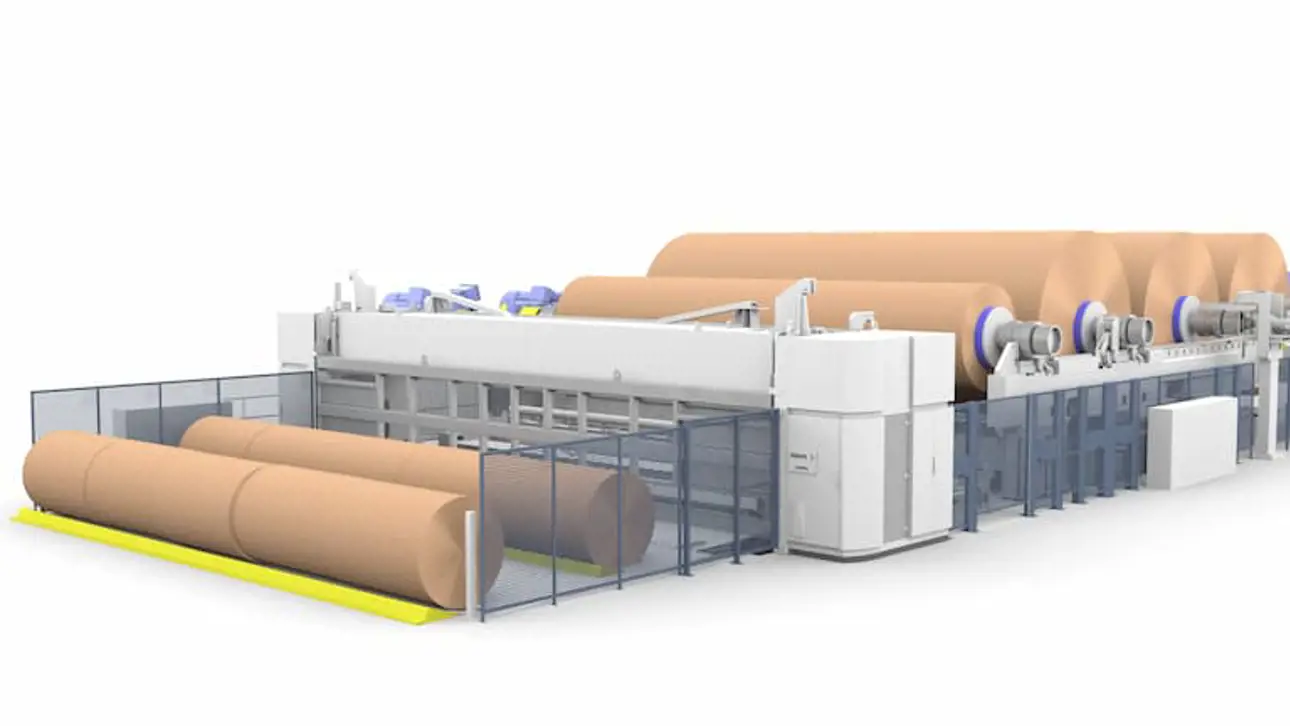

Winder improvements for board and paper making

Solutions for improved production and maintenance efficiency

Our winder solutions improve production or maintenance efficiency and ensure good customer roll performance at the printing house or converting plant. The improvement process looks deeper into your winder to identify and solve known or hidden problems and to find opportunities for improvement.

Excellent customer roll runnability in the printing press or converting machine

More capacity and less manual work through automated functions

Extended winder lifetime

Improved occupational safety

Enhance efficiency and reliability for winders

The traversing end-gluing device for winders not only enhances the efficiency of your operations but also contributes to a more reliable and cleaner work environment, offering a step towards a more streamlined process. The automatic tail gluing feature reduces manual labor at the winder, thereby improving safety. The device’s reliability is improved by fewer components, while the hot-melt glue ensures strong, durable bonds. Maintenance is simplified thanks to easy cleaning, a convenient design, and fewer nozzles required. Compatible with most winder types, its servo technology enables fast and precise control over the gluing process and rapid linear movement.

Solutions to your needs

Your improvement solution is created based on the analysis and your targets.

Customer roll quality improvements

- Excellent customer roll runnability in the printing press or converting machine

- Minimized surface and core waste

- Minimized dust content in the roll

Capacity and runnability improvements

- More capacity and less manual work through automated functions

- Easier production planning with automatic back splicing

- Better runnability through elimination of disturbances like bouncing and vibration

- Improved occupational safety

Condition management improvements

- Fewer unexpected failures – more production

- Extended winder lifetime

- Increased knowledge and motivation of operators and maintenance personnel

Do you want to know more about process upgrades?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usLearn more about our winder offering