OptiPress Linear

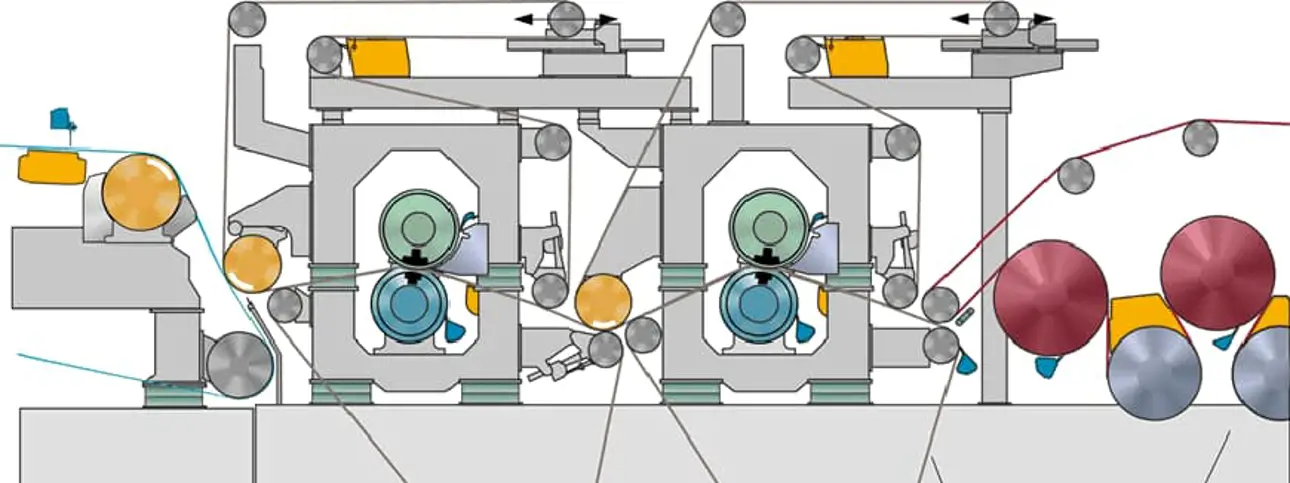

Double-nip press with linear web run

Wet pressing is a vital part of paper and board processing and benefits both runnability and quality. The ultimate target of wet pressing is to increase sheet dryness to ensure paper and board machine drying capacity and also to enable web runnability at the beginning of the dryer section. The press section also has a great effect on sheet surface properties. Valmet’s OptiPress Linear, double-nip press with linear web run, is an ideal solution to fulfill papermakers’ requirements for effective pressing.

Excellent runnability and high production efficiency

Outstanding end-product quality

Good moisture profile and high dewatering capacity

Potential for furnish optimization

Excellent end product properties, high dewatering capacity and good runnability

The operating performance of OptiPress Linear press section has proven that the design principles employed – no open draws, shoe press technology, and full-width tail threading – provide excellent end-product quality, high-level dewatering capacity as well as good runnability. This results in a press section where press-related runnability bottlenecks, such as open draws, are a thing of the past.

The closed web run significantly reduces web breaks and thus improves runnability. OptiPress Linear press section also provides very good paper and board quality with symmetrical sheet properties, good moisture profiles, excellent dry content, and high production efficiency.

Shoe pressing with proven SymBelt technology

A press section with two shoe nips provides superior quality properties at the desired bulk level. As a rule of thumb, the first shoe press nip controls the bulk, and the second press nip controls the dryness and bulk.

OptiPress Linear features SymBelt shoe press technology, which provides longer dwell times and higher press impulses that improve dryness after the press section. A high web dry content brings savings also in drying energy. The two straight press nips of OptiPress Linear produce a strong web and ensure good moisture profile in the web after the press section.

OptiPress Linear for containerboard grades.

Want to talk to our press section experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsExplore our latest board and paper press releases

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States

- Jul 8, 2024Discover Valmet MTC Wizard at Tissue Innovation Days 2024: the latest technology enhances Client benefits in Tissue Folding

- Jul 2, 2024Valmet to supply a high-capacity winder to Wuzhou Special Paper in China

- Jun 26, 2024Valmet to supply both a papermaking line and a paper machine rebuild to a customer in Asia-Pacific

- Jun 25, 2024Valmet to deliver a tissue machine to Andhra Paper in India

- Jun 19, 2024Valmet receives the second order of converting lines to Metsä Tissue in Mariestad, Sweden

- Jun 13, 2024Valmet and Flootech enter partnership to advance water treatment for the board, paper and tissue industry

- May 30, 2024Valmet enters joint venture with Körber to advance the digital offering to the tissue industry

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China