Improve performance, quality and efficiency in wet pressing

Metal belt technology

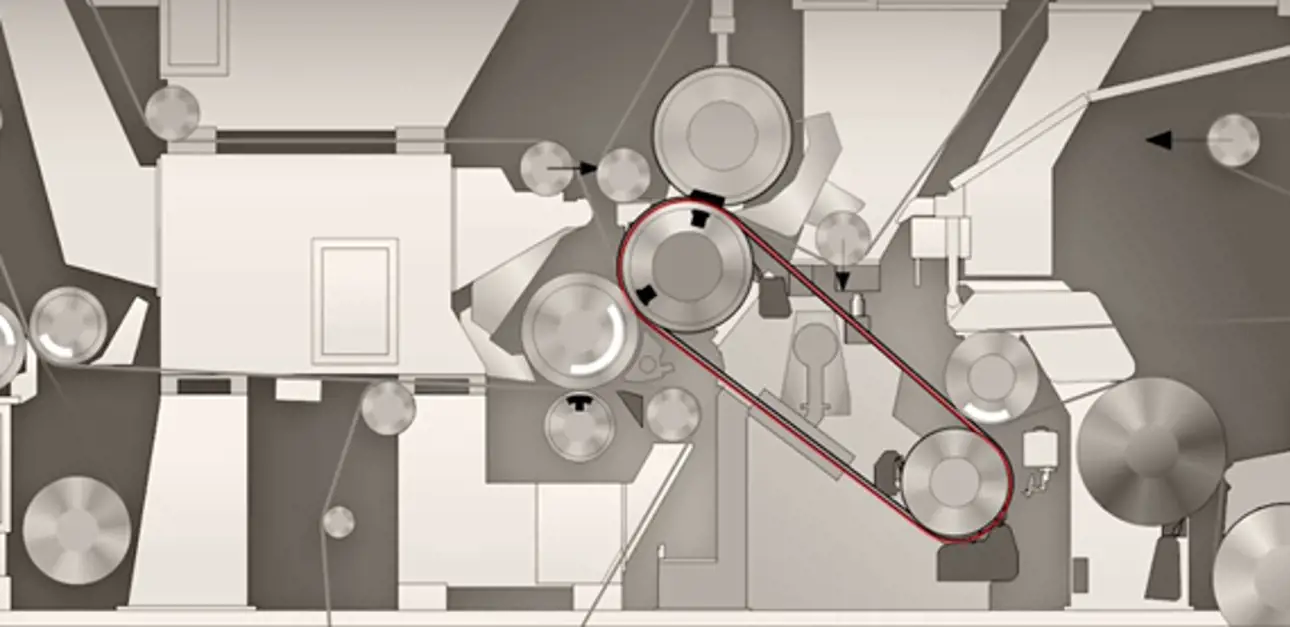

The newest OptiPress Center press section concept has a smooth, heated metal belt that goes around the center roll and guide stretcher roll. The steam-heated metal belt improves press section performance, as the temperature of the paper web increases on both sides of the press nip.

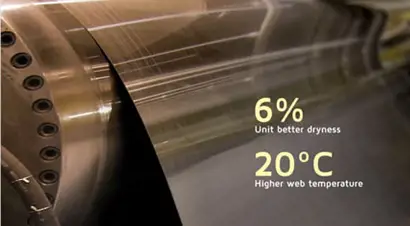

Up to 20% more effective water removal at press section with metal belt technology

Metal belt technology has made a major breakthrough as a revolutionary new calendering concept for papermaking. Now the benefits can also be utilized in wet pressing, too. The OptiPress with metal belt technology boosts production capacity by eliminating unsupported open draws. It also increases the dry content after the press by up to six percentage points due to more effective water removal at the press nip and evaporation over the hot metal belt. Furthermore, it improves several end product qualities, such as strength and porosity.

Ideal concept for rebuilds

The new concept is compact and increases dry content significantly, making it ideal for rebuilds to increase capacity by removing bottlenecks such as limited drying capacity or runnability.

Valmet’s new metal belt technology closes the draw between the press and dryer section, increases dryness and improves end-product qualities such as strength and porosity.

How do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. But where do you start? Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Download e-bookCustomer success story with metal belt technology: Even thinner label papers thanks to new metal belt

PM 8 at the Tervasaari mill, which produces label release base papers, went through a renovation that included a press section rebuild along with modifications throughout the paper machine line. The targets were to increase speed and further improve paper quality, as well as increasing the capacity of the paper machine by 30,000 tonnes annually.

The heart of the investment in PM 8 was the rebuild of the existing center roll-based press section with Valmet’s latest innovation: a new steam-heated metal belt application.

The new press section with metal belt technology has delivered what was promised: The draw between press and drying section has decreased significantly. Water removal is more effective as the dryness after the press has increased significantly. The concept also has positive effect on paper quality. Runnability has also improved and thanks to the rebuild the maximum speed of the paper machine has considerably increased.

Want to talk to our press section experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsExplore our latest board and paper press releases

- Jun 13, 2025Dr. Jin-Doo Kim awarded with a Medal for Extraordinary Achievement for decades-long work for promoting board and paper technologies

- May 26, 2025Valmet to supply a fifth Advantage tissue production line to Lila Group in Turkey

- May 21, 2025Valmet to supply a major paper machine rebuild to Sylvamo in North America

- Mar 27, 2025Successful start-up of Zhejiang Forest United Paper’s PM 6 production line

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China