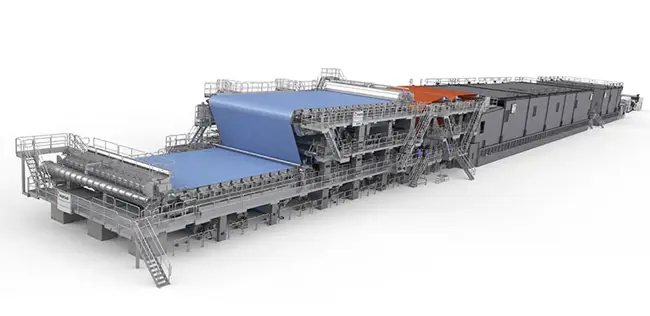

OptiRun dryer

Excellent runnability and speed records

Valmet’s OptiRun dryer section portfolio is able to provide perfect solutions for all customer needs. OptiRun dryer sections use proven technology and have a great number of references, including many of the world’s fastest machines.

Excellent runnability and productivity

Uniform quality and profiles

Low life-cycle cost

Secure investment

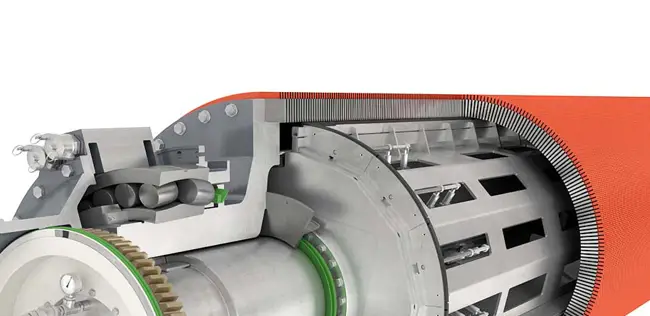

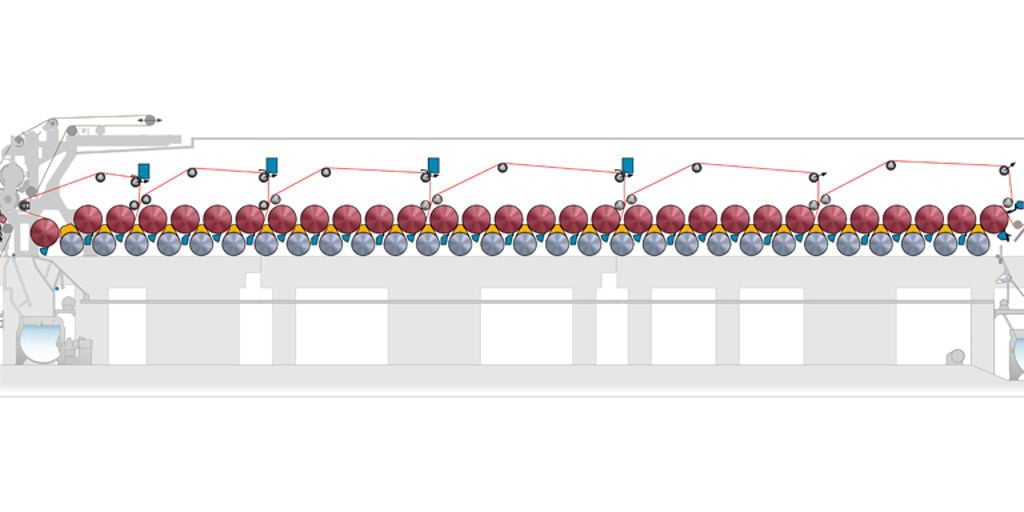

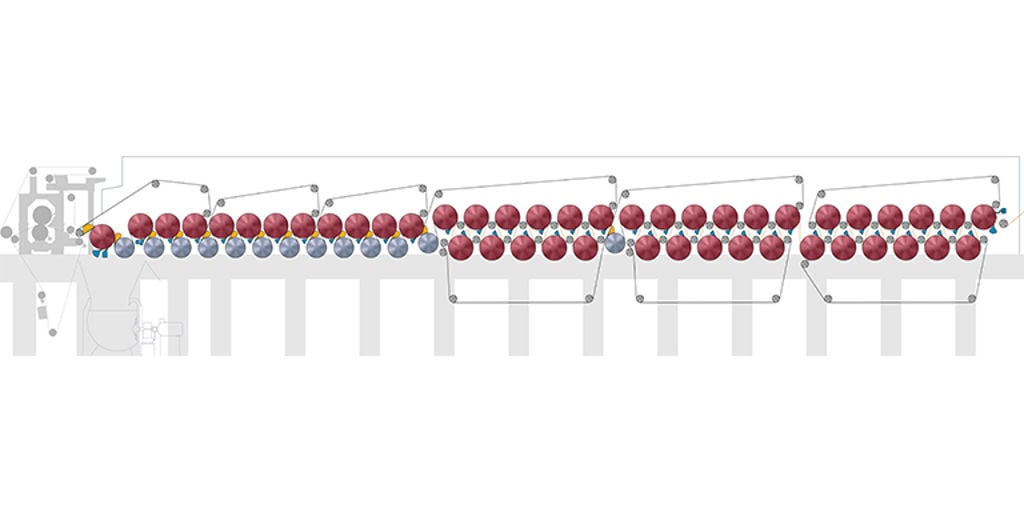

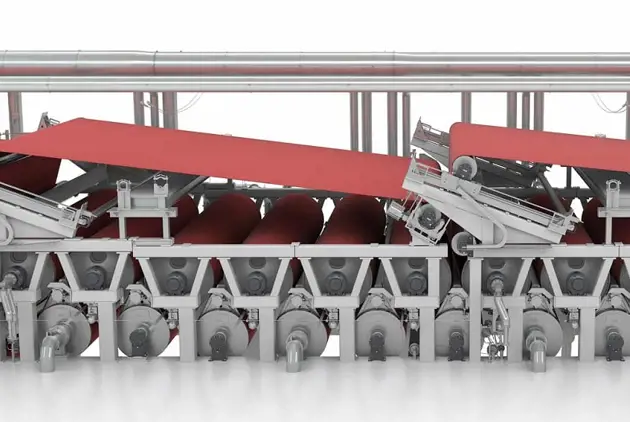

The OptiRun dryer section family consists of four solutions that cover all dryer geometries, providing optimal drying capacity and excellent runnability. Each dryer section features UnoRolls, VacRolls and/or Edge VacRolls, depending on machine speed and paper/board grade, in order to ensure smooth tail threading, runnability and energy efficiency. OptiRun dryer sections are available with both steel and cast iron dryer cylinders.

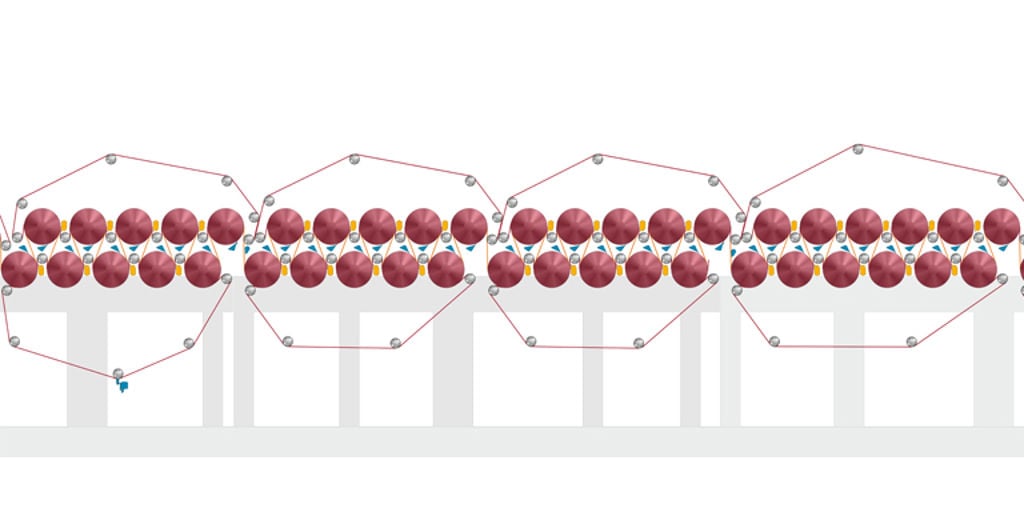

Optimal geometry ensures total web support throughout the dryer section. Support after the press and efficient runnability components produce a high strain potential, low porosity, and improved internal strength. In addition to conventional geometry, these dryers are also available with a compact geometry. The benefits include energy savings thanks to using fewer fans, improved drying capacity due to the large cylinder wrap angle, and minimal sealing wear against roll/fabric due to minor fabric bending.

OptiRun paper machine dryer solutions

OptiRun Single - For single-fabric dryer sections

- Excellent runnability and productivity thanks to total web support

- Uniform quality and profiles

- Secure investment and low lifecycle costs (steam, electricity, maintenance, etc.)

- Available in conventional and compact geometries

OptiRun Double - For double-fabric dryer sections and groups

- Double-fabric dryer groups boost drying efficiency by supplying heat to both sides of the paper

- Available in conventional and compact geometries

OptiRun Hybrid - For dryer sections with single- and double-fabric dryer groups

- Combination of single-fabric dryer groups at the beginning of the dryer section, followed by double-fabric dryer groups

- Combines best features of single- and double-fabric groups

- More compact dryer section with same drying capacity

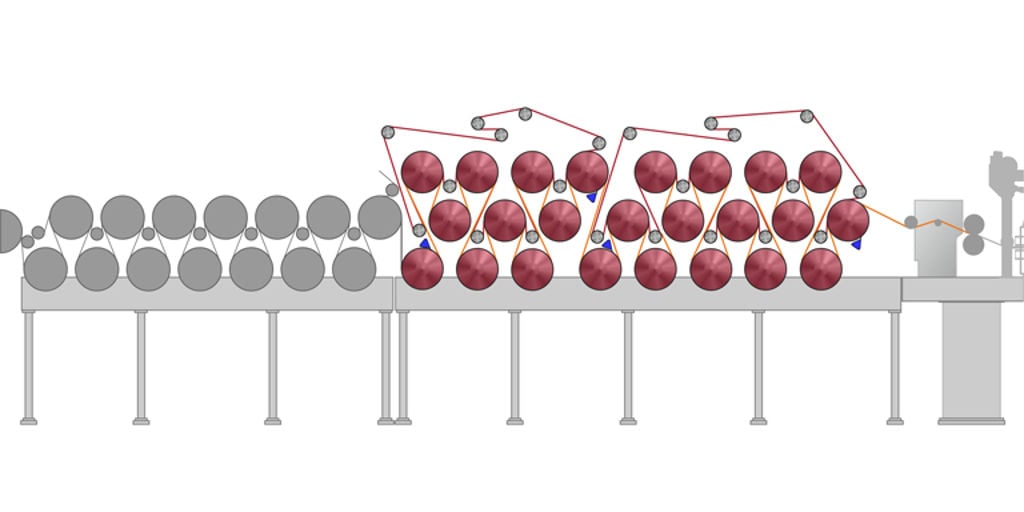

OptiRun Triple - For triple-tier dryer sections and groups

- Typical rebuild solution for adding drying capacity when space is limited

- For heavy board grades and pulp machines with low speed range up to 600 m/min

Do you want to know more about Valmet's compact concept?

OptiRun compact concept is a game-changer in paper machine dryer sections. Ensuring good runnability, improved drying efficiency and excellent tail threading, this is the biggest change in drying section design in the last 35 years.

Read the article

Want to talk to our drying experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsLearn more about the services for dryer section

Planning a grade conversion?

The world is changing fast; the consumption of newsprint and printing paper is decreasing and the consumption of containerboards or cartonboards are increasing. An old paper machine can be updated with a grade conversion rebuild to produce more profitable products. Turn a new page for your paper machine with the help from Valmet.

Discover moreExplore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy