Closer is better – The Valmet compact dryer concept

Dec 5, 2023

Valmet’s OptiRun compact concept for paper machine dryer sections ensures good runnability, while delivering better drying efficiency and absolutely excellent tail threading. It’s the biggest change in dryer section design in the last 35 years.

Valmet’s compact concept brings a new level of performance to dryer sections, however, it has been under development for over 15 years. Juha Kaihovirta, Product Manager, Dryer, Valmet, explains. “Back in the early 2000s, paper machine speed was the main driving force for development. As machines got faster, runnability became more and more important, especially with lightweight paper. That’s why we started working on runnability systems and one of our ideas was to position the VacRoll closer to the drying cylinder to create underpressure.”

“Then the global recession happened and the market changed totally,” says Kari Juppi, Senior Development Manager, Dryer, Valmet. “Fewer machines were sold and these were smaller, slower and narrower, so there wasn’t so much need for runnability systems. It took years before the market recovered. However, although this delayed development, we had already tested the first compact concept on our pilot machine in Jyväskylä. It gave very good results.”

Valmet’s compact dryer concept has given great results.

Improved runnability and web support

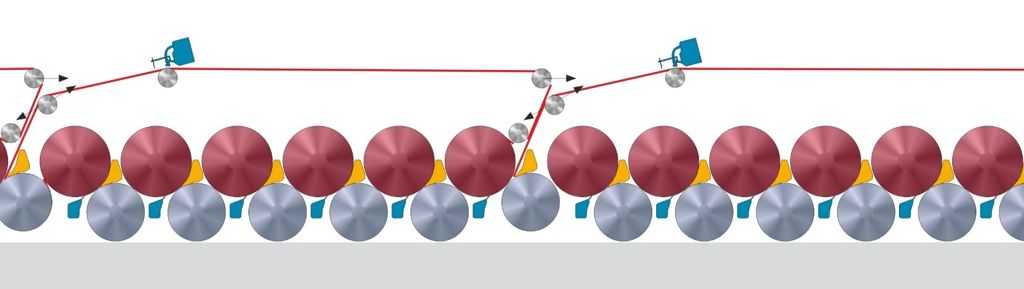

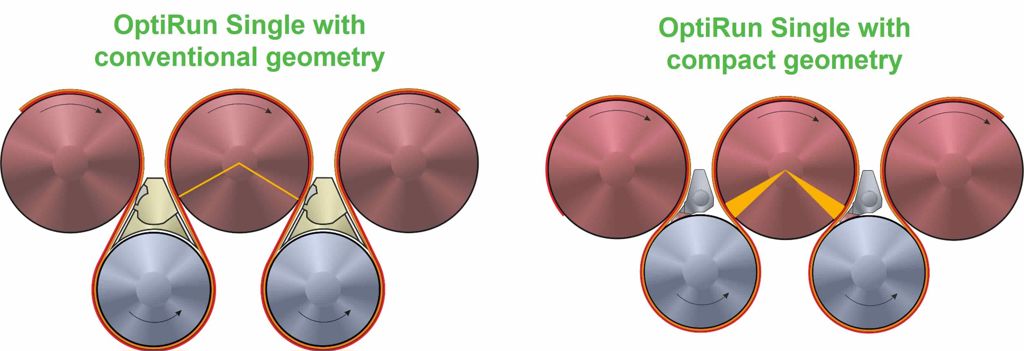

“A common problem in dryer sections is that the paper web follows the hot dryer cylinder, which can lead to wrinkles, web breaks, and poor runnability,” explains Elina Villikari, Senior Manager, Runnability Systems, Valmet. “With conventional dryer geometry, there’s a quite a long distance between the vacuum roll and the dryer cylinder. This means that the fabric has a long free draw, the vacuum is relatively weak and the web isn’t supported.”

“Now, with the Valmet compact concept, we can focus underpressure where it’s needed and solve runnability problems throughout the entire dryer section, and in different dryer groups,” says Villikari. “In the OptiRun compact concept, the VacRoll is positioned closer to the dryer roll than in conventional dryers. This enables us to use high underpressure all the way from cylinder to VacRoll, which supports the web very efficiently, resulting in better runnability. Because there’s now only one underpressure zone, the control and operation of the system is much easier. Together, these elements ensure better drying performance, better runnability and maximum web stability.”

In Valmet’s compact dryer concept, the distance from the vacuum to dryer rolls is shorter than in conventional dryers and the runnability component is also more compact.

Proven in practice

“After excellent experiences on our pilot machine, we began to deliver the compact concept to customers a few years ago,” says Jarkko Nurmi, Product Manager, Impingement Drying, Valmet. “Our first delivery in China had a grooved roll with a compact suction box. We installed it in the last pre-dryer group because that was an easy and safe location from a runnability point of view. It gave very good results.”

“The next delivery was to a customer in Europe. They started with one box first, and they soon ordered two more. Now, with our most recent delivery, also in Europe, we have installed the compact concept throughout the dryer section,” Nurmi says. “It includes a total of twelve pre-dryer boxes in the second and third dryer groups, and nine after-dryer boxes. It’s been running for a couple of years now and the results are so good there’s no question about how well it works. It’s a proven concept.”

The results are so good there’s no question about how well it works.

Big benefits and more flexibility

“The compact geometry increases the wrap angle of the web on the cylinder surface, giving a higher drying capacity, with better contact and a longer wrap on the dryer roll,” says Nurmi. “However, I would say that one of the biggest benefits with the compact concept – maybe the number one thing – is that tail threading is absolutely excellent. “With conventional geometry, there’s a really long pocket zone, with an underpressure of only 200-400 Pa. With the compact geometry, there’s a much shorter distance between the fabric and dryer cylinder and vacuum roll. The short distance enables a single high underpressure zone, which results in much better tail threading.”

“We have also learned a lot from running the compact geometry in production machines,” adds Villikari. “For example, it can improve energy efficiency, as well. Compared to the previous models of the Valmet Hirun System with conventional geometry, Hirun Compact can achieve considerable energy savings as we have also found that we don’t need such a high under pressure thanks to the optimal geometry. This gives us flexibility to optimize underpressure levels throughout the dryer section and reduce relative energy consumption further.”

Hirun Compact can achieve considerable energy savings thanks to the optimal geometry.

Taking the compact concept further

“Now that we know the vacuum levels can be lower, we can also think about reducing the amount of duct work that’s needed and using lower powered fans,” says Juppi. “When we minimize air use, we can also minimize energy consumption and lower system costs.”

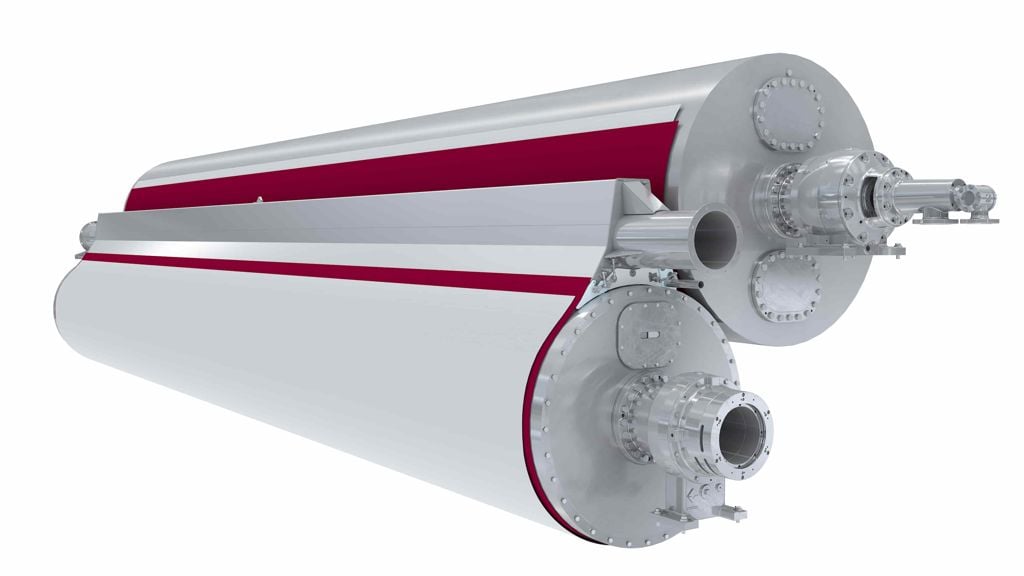

“So far we have delivered the compact concept to high-speed machines with VacRolls and OptiRun drying systems,” adds Kaihovirta, “but we are also developing the concept for other types of machines. For example, we will soon be delivering a compact concept for a mid-speed machine that uses UnoRolls in the dryer section. This means that Valmet can now offer the compact concept for two types of rolls: VacRoll and UnoRoll, and in the future, we’ll have yet more to offer.”

Text: Peter Cura

Want to talk to our drying experts?

If you wish to get further information, fill in the contact form and our experts will contact you shortly.

Contact our expertsInterested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsRead more

Want to talk to our drying experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our experts