Valmet IQ Total Ash Measurement

The accurate scan averages and high-resolution CD profiles measured by Valmet IQ Total Ash Measurement (IQ Total Ash) provide a solid foundation for Valmet’s machine-direction total ash content controls.

Precisely control ash and related quality properties

Lower furnish costs by optimizing ash content and composition

Reduce startup waste with real-time ash measurements

Precise ash control

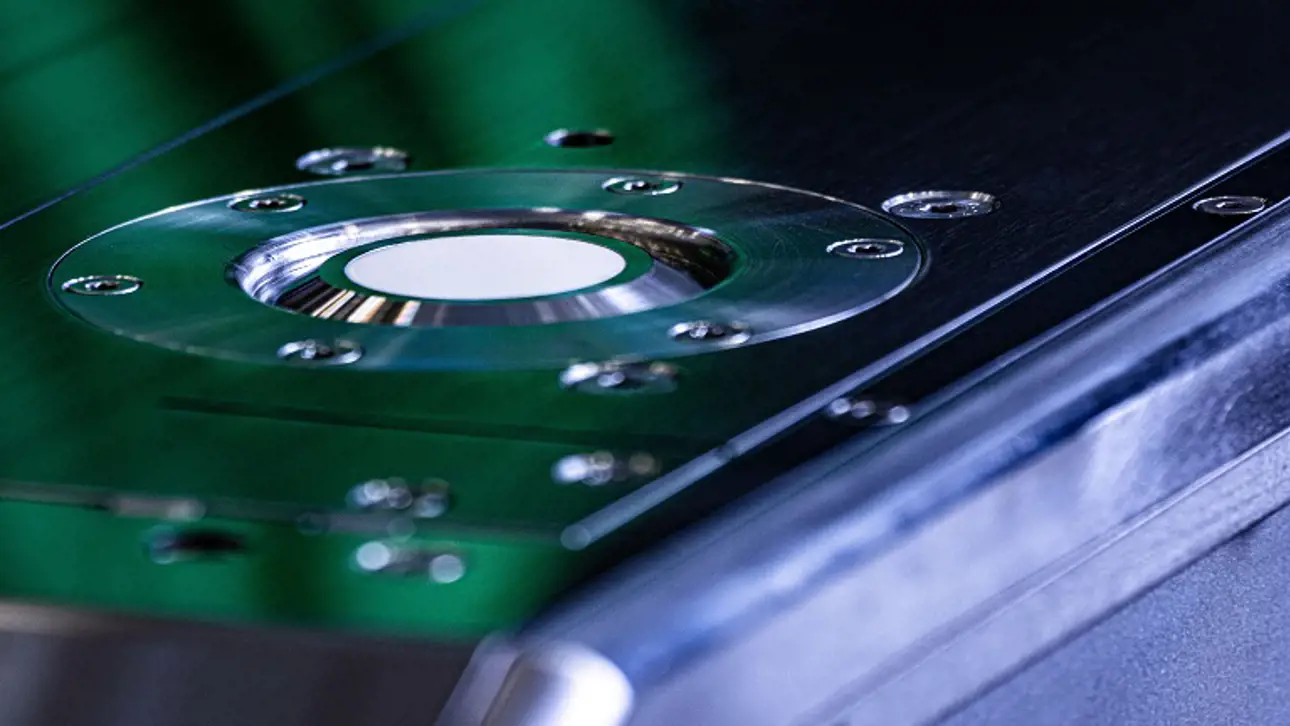

X-ray radiation from an Fe55 nuclear source is preferentially absorbed by the inorganic material in a paper sheet. As ash content increases, transmitted radiation that is captured by the ion chamber detector is reduced. This basic measurement principle is refined by using special sensor-design techniques and measurement diagnostics to provide the stable, high-resolution measurements needed for precise control. Ash content is factory calibrated for sheets containing clay or calcium carbonate or titanium dioxide.

Accurate measurement

For total ash measurement in papers containing clay or other fillers, the Valmet IQ Total Ash Measurement delivers accurate, high-resolution CD profiles of total ash in papers containing clay or other fillers. Air density, temperature and other variables that may affect the measurement are automatically compensated through intelligent diagnostics and processing.