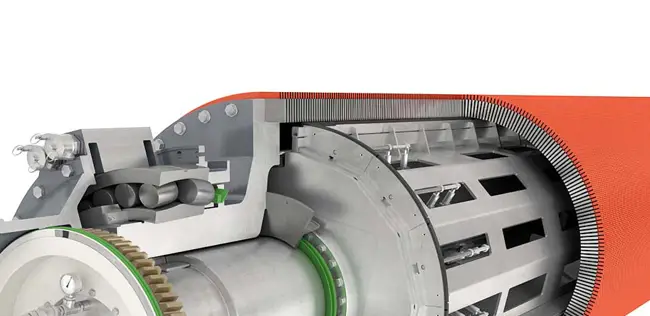

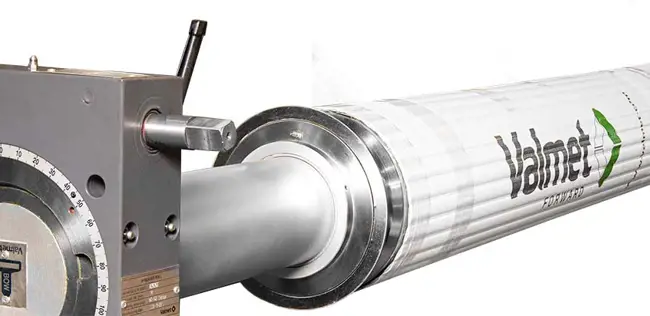

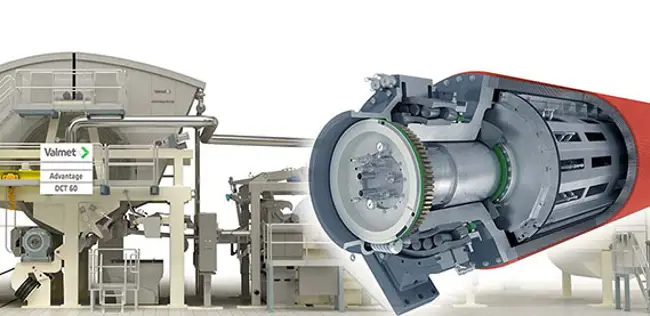

Rolls for tissue production

Maximum performance with high-quality rolls

With over 50 years of roll manufacturing experience, innovative R&D, and the process know-how of a paper machine builder, Valmet offers highly reliable roll solutions that provide maximum performance and extend maintenance intervals for your tissue making line.

Excellent operating performance

Low vibration levels

Fewer sheet breaks

The latest manufacturing technology

The long operational life of new rolls is ensured by accurate dimensioning, durable materials, and functional roll design. With decades of experience, we have access to a vast library of original roll manufacturing drawings, which are used to engineer fully compatible spare rolls for all tissue machine applications, regardless of the original machine supplier.

Roll solutions for all needs

Roll upgrades |

Improved spare rolls |

Spare rolls |

|

|

|

Value added with Valmet's roll solutions

| Revenue | Life cycle cost | Assets | Minimizing risks |

|

|

|

|

References and articles

keyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}