Enhanced recovery boiler efficiency and availability

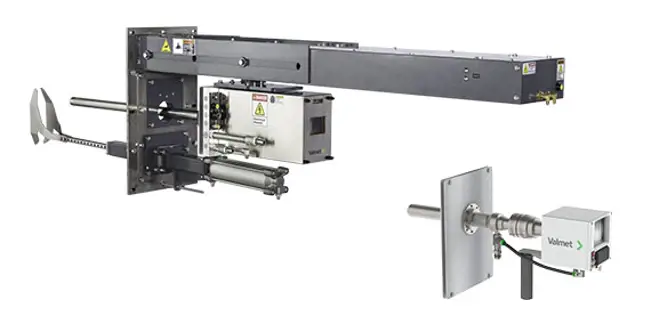

Valmet Recovery Boiler Optimizers

The Valmet Recovery Boiler Optimizer and Valmet Recovery Boiler Sootblowing Optimizer help ensure you get maximum performance out of your recovery boiler.

1-4% - increased steam production

30-60% - higher green liquor stability

40% - extended recovery boiler operation

2-6% - higher liquor throughput

Improve energy generation and chemical recovery, while maximizing green liquor concentration with the Valmet Recovery Boiler Optimizer. Smart controls stabilize and carefully regulate the combustion of black liquor. The optimizer increases liquor throughput capacity and enables longer operation periods with better safety from a stable furnace.

The Valmet Recovery Sootblowing Optimizer goes hand-in-hand with the Recovery Boiler Optimizer. The amount and quality of dust and potential carry-over are a direct result of the burning process in the boiler furnace. By optimizing sootblowing, you can decrease fouling and improve the recovery boiler efficiency, while also extending operation with longer water washing intervals.