Increased winder capacity through optimized set change and gluing

Dec 11, 2018

When Steinbeis Papier in Glückstadt, Germany, started to develop papers for high-performance inkjet printing, they needed to make sure their winder was up to the challenge. They turned to Valmet to improve the winder set change time.

In 2015, Steinbeis Papier in Glückstadt, Germany, was making improvements on its PM 4 papermaking line. The mill was developing papers for high-performance inkjet printing, which demanded more from the capacity of the existing winder. The development work on lightweight coated (LWC) grades for high-performance inkjet printing meant that the customer rolls were smaller than before, making the set change times even more important.

Need for increased capacity

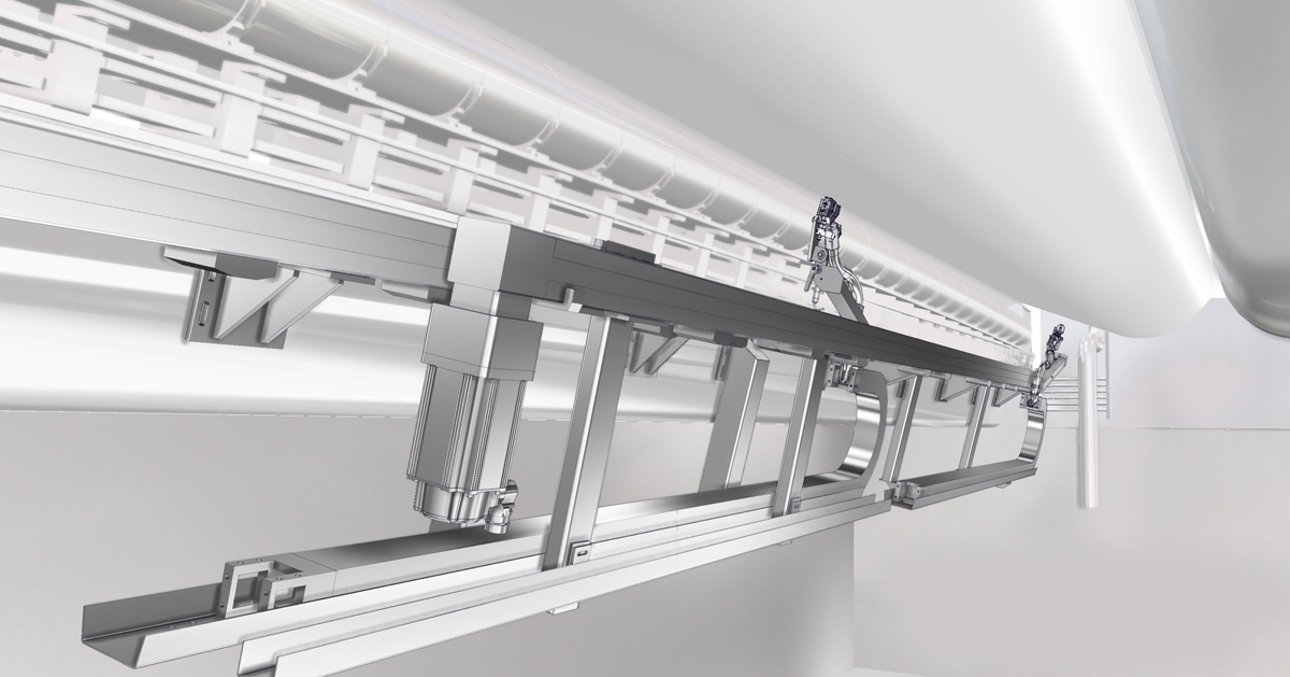

Valmet had already delivered an OptiWin Belt winder to Steinbeis Papier back in 2000, but there had been no rebuilds since the start-up: the winder had fulfilled its task, as it was designed to meet the previous production targets. Steinbeis Papier chose Valmet as their partner to develop a solution to increase the winder capacity and to implement the necessary work.

From taping to gluing

An evaluation of the potential capacity increase showed that end taping during the set change was one of the biggest time-consumers, with a direct impact on capacity. The plan was to replace the time-consuming end taping process with Valmet’s traversing end-gluing device. The delivery also included improved set change equipment – a roll ejector – which ensures further time savings and reliable operation at higher throughput rates. Steinbeis Papier was very convinced of the solutions Valmet had suggested.

Rebuild during scheduled shutdown

Both parties were pleased with the close cooperation during the project phase. The rebuild was carried out during a short, scheduled annual shutdown, and the optimizations were carried out together with the customer during the start-up. Valmet’s improvements brought the desired results and trouble-free operation.

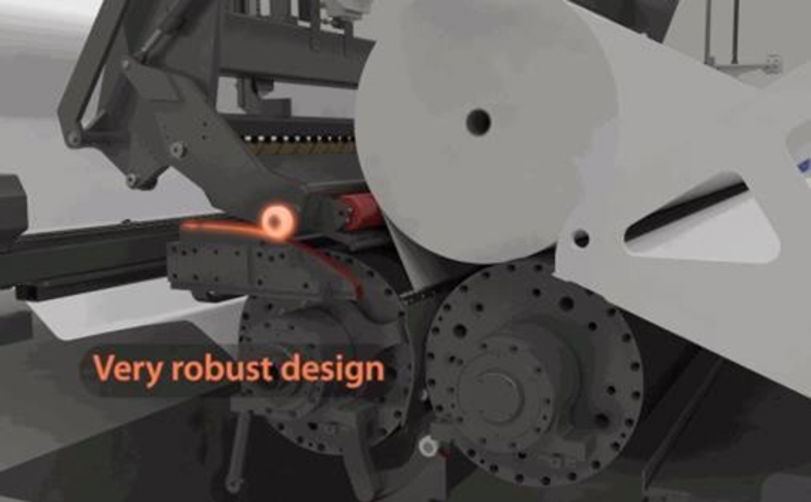

End gluing with a traversing nozzle

Automated end gluing brings several benefits

- Less manual work at the winder

- Reliable

- Fewer mechanical components

- Use of hot glue

- Less need for maintenance

- Easier to clean than the conventional systems

- Home position on the side of the paper web

- Only two nozzles compared to conventional systems with 30–100 nozzles

- Fewer spare parts required

- Clean machine surroundings

Technical solution

- Applicable with most winders

- Fast, precise control of gluing due to servo technology

- Fast linear movement.

When a set change is carried out at the winder, a strip of glue is applied to the paper web in the cross direction by a fast-moving, servo-controlled nozzle. The small inclination angle between machine direction and nozzle movement – adjusted for the web speed – ensures that the glue strip is straight. Traversing end-gluing is precisely controlled, so the glue does not get too close to the edges of the web or the slittingpoints.

The cores are received with suction cups from the core trough with vertical movement. When the customer rolls have been ejected from the winder, the core loader loads the cores accurately into the nip of the winding drum. The improved set change equipment performs the set change faster than a conventional system because a low rotational speed is no longer required during the end-gluing operation. Also, a counter blade is no longer needed for the web cutting.

Related articles