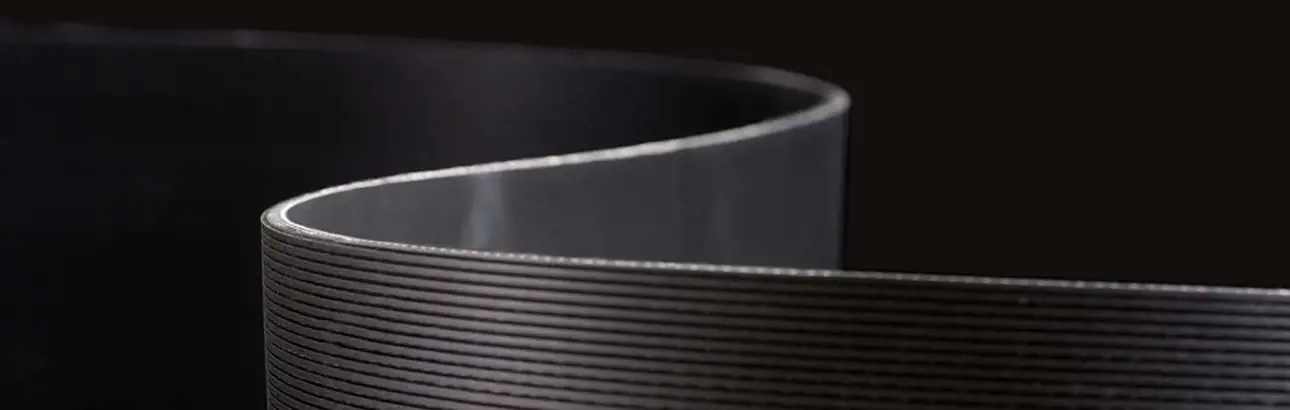

Valmet Black Belt shoe press belts for board and paper machines

Efficient dewatering and excellent wear resistance

Valmet Black Belt is a unique shoe press belt made of high performance elastomer material reinforced with dimensionally stable synthetic yarns. The belt is available in different reinforcing structures and surface options to fulfill the demands of every shoe press. Black Belt is wear, chemical and heat resistant which ensures long and trouble free running.

Excellent wear resistance

Efficient dewatering

Chemical and heat resistant

Long lifetime

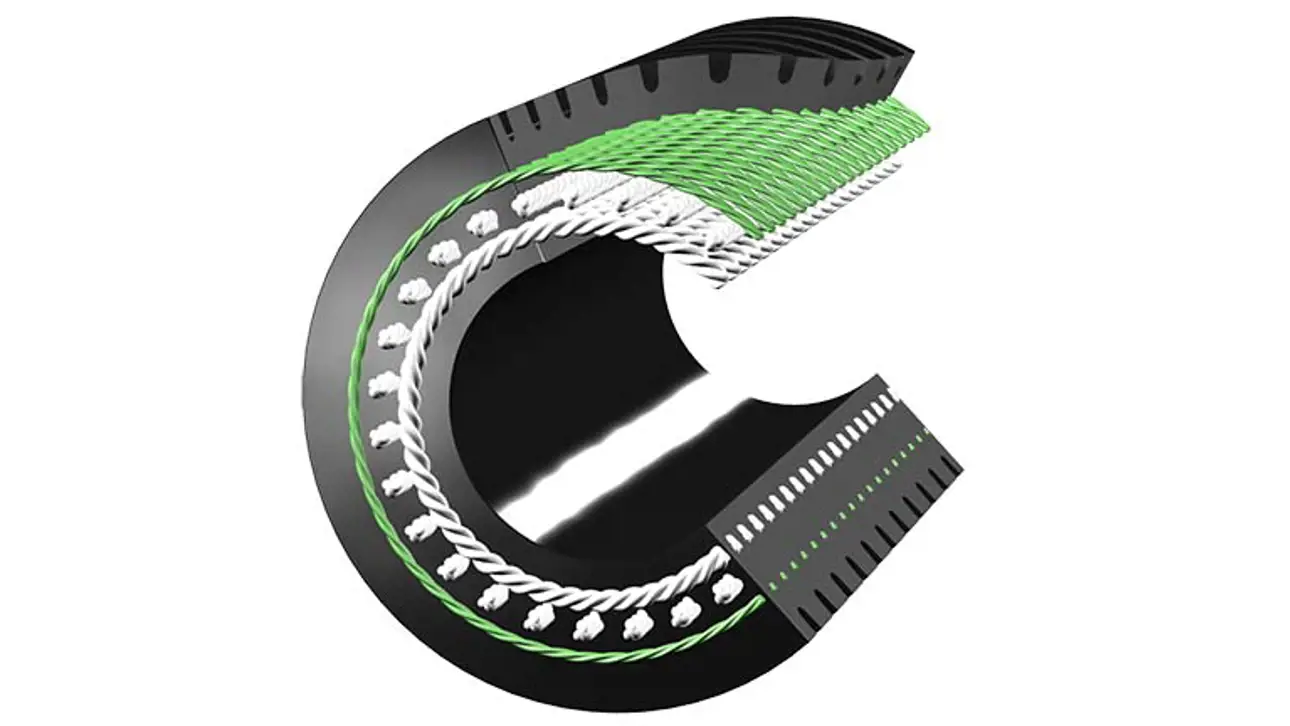

Valmet Black Belt H

Black Belt H (high performance) is especially designed for the shoe press positions of board and paper machines. With the H design you reach longer lifetime and constant dewatering. The belt features:

- High durability

- Better dewatering with decreased water absorption and less decrease in void volume

- Minimized crack development

- Partly transparent elastomer for exact control of the casting process and quality

Need support regarding shoe press belts

Our belt professionals are here for you. Contact us and we'll revert soonest.

Contact usBelt structures

Black Belt is made with double or triple layer reinforcement to fullfil the requirements of every shoe press.

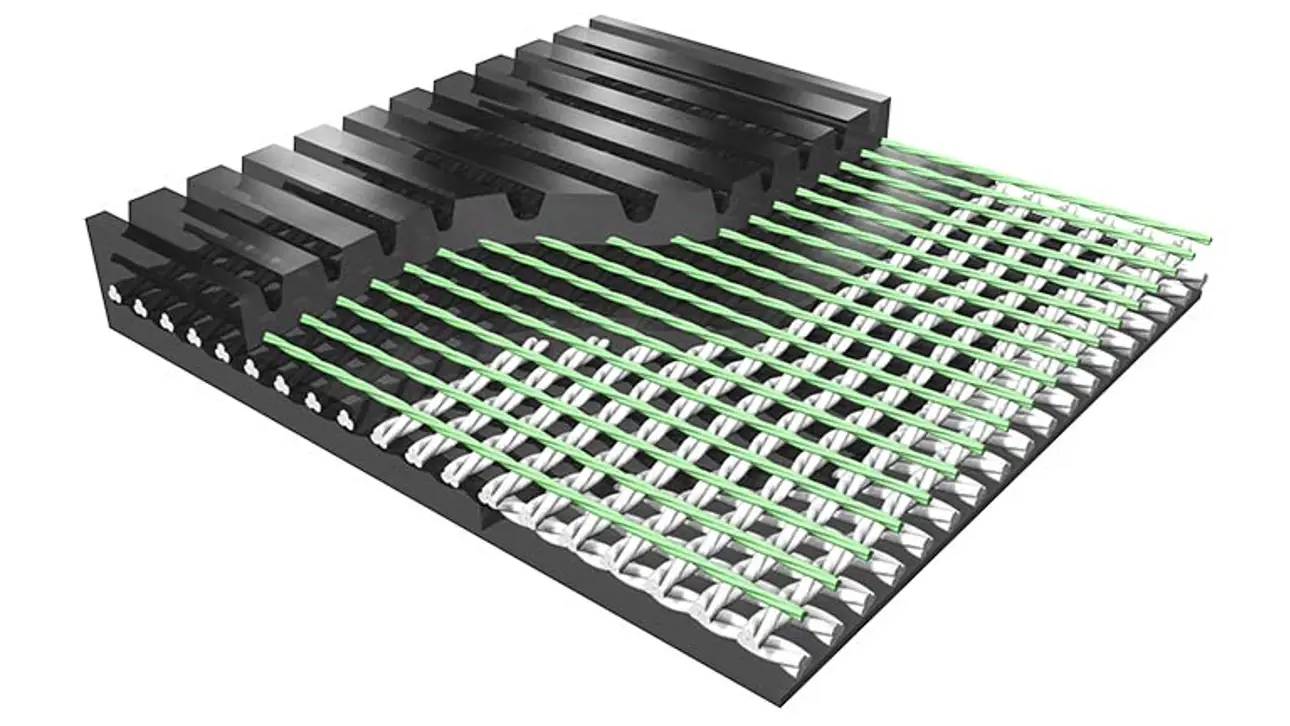

Belt surface options

Smooth

Plain belt for shoe presses with no nip dewatering.

Discontinuous grooves (DG)

Discontinued grooves prevent water to flow backwards in the nip.

Semi grooved (SG)

Semi-grooved belt for high water contents to add the void volume of the press felt. The water is absorbed out of the grooves by the felt. Target grades pulp and fluting.

Grooved

Grooved belt for fast paper machines

High density grooved (HD)

High density grooves for marking prone positions.

Articles and news