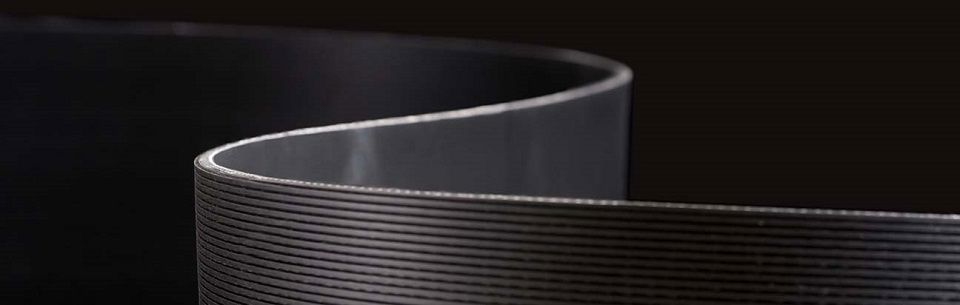

When the quality of Valmet Black Belt H leaves you impressed

Valmet Black Belt H was introduced to the market in 2017. One of the first board makers to run a trial on the new belt was Buchmann Karton – making them a satisfied customer ever since.

Buchmann Karton, today part of the Weig Group, is a German company with a history of over 120 years and an extensive product portfolio for folded boxboard. Buchmann Karton has around 330 employees working at its mill in Annweiler, where it produces 260,000 tons of cardboard each year.

For a good belt supplier, Buchmann Karton has precise requirements.

“We expect deliveries to be on time and assistance to be available during belt changes if something unpredictable happens. We also value services that fit our current needs but hope to get insights for future development of belts too,” says Thomas Kurz, Leader of the board machine BM3 at Buchmann Karton.

According to Kurz, Valmet has been able to fulfill the requirements in an excellent manner.

“I personally appreciate the good cooperation between Valmet and our machine crew very much – it is only through continuous interaction that we will be able to improve our performance. Throughout the years, we have discussed various issues related to belts with Valmet and implemented changes in our production parameters according to the advice we have received,” he says.

Valmet Black Belt H leads to improved dry content at BM3

Buchmann Karton was one of the first board makers to run a trial with Valmet Black Belt H when it was introduced back in 2017. The new design was to feature high durability, improved dewatering with less decrease in void volume over time and minimized crack development.

“Right from the start, we were satisfied of the performance of Valmet Black Belt H and have continued to rely on that design ever since. We have been able to increase the dry content after the press section by as much as 1-2 percentage points over the years, which is an excellent result. What is also worth mentioning, is that the belt keeps its dewatering properties throughout its lifetime, which in our case has varied between 400 and 800 days,” Kurz says.

Building the future together

Thomas Kurz expects Buchmann Karton to continue producing cardboard successfully for the next generations. The mill and its processes are being constantly developed to meet the company’s sustainability targets and growing customer needs.

“For a successful future, we will surely need to cooperate with partners such as Valmet. When it comes to belt development, I believe Valmet will continue adapting to our changing requirements as they have until now,” Kurz says.

Text: Marianne Valta